I think you should perhaps, at times, question your mechanic's sources.

oil on the good foot

Collapse

X

-

This is the one that I installed on my XS11.

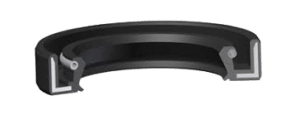

It worked for a few thousand miles. It was during the hot summer months pushing a sidecar. I'm guessing it got real hot and started to wear. The install must have gone well because it did not leak for a long time indicating a wear issue and not a tear or abrasion during install. It was also not a directional seal as was the factory original. I'm not sure if the double lip was a factor. I had posted here info from a seal company that a double lip seal needs lubrication in between the two to keep it from drying out and abrading. I used red rubber grease in between but I suspect that is a low temp grease and failed with high heat. Maybe Mobile 1 synthetic grease next time with a Viton seal. I will install this soon.

Comment

-

Another thought: If Buna is good until 257°F and your oil is around 250°F on a hot summer day. Well...there it is. It will work but not forever. It would have to start breaking down in that environment. Starting with a weep and ending with a larger leak. Wear issues.Comment

-

Phil you have the buna https://www.oringsandmore.com/metric...-ref-cr563065/

I now have the viton https://www.oringsandmore.com/fkm-oi...rice-for-1-pc/

80 GComment

-

I went back and checked my purchases and yep, Eric you are right, Buna rubber for the ignition side. The one I used for the alternator side I bought from a different source and they didn't list which type it was, but it also is still holding up.2H7 (79) owned since '89

3H3 owned since '06

07 Triumph Tiger 1050

"If it ain't broke, modify it"

☮Comment

-

GEARBOX SEAL: FKM OR NBR ?

How self-evident is the correct sealing of a gearbox? A standard rubber seal is used in many gearboxes. But these seals often do not fulfill the requirements of a gearboxes due to the high speeds, dynamics and duty cycle of the application. And what if an application is placed in a special environment? Or when it is a special application?

How self-evident is the correct sealing of a gearbox? A standard rubber seal is used in many gearboxes. But these seals often do not fulfill the requirements of a gearboxes due to the high speeds, dynamics and duty cycle of the application. And what if an application is placed in a special environment? Or when it is a special application?

In this article we discuss the characteristics and properties of High-end sealing materials and the questions that you might ask yourself before you make a choice.

GEARBOX SEALING MATERIAL

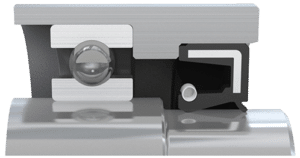

To keep the lubricant inside and contamination outside of our gearboxes, Apex Dynamics is using seals for its gearboxes. The seals on the input and output side of the gearbox of Apex Dynamics are vulcanized around a steel support, so that the seal is form-retained and can always be found with a metal detector. Depending on the application, two high-quality materials are used as standard: FKM and NBR.

VITON® / FKM SEAL

VITON® / FKM SEAL

Viton® is the trade name of this type of elastomer from inventor Dupont. But in practice we also call it Fluorocarbon or FKM. In this article we will use the name FKM.

NBR SEAL

NBR is also called Nitrile or Nitrile rubber and stands for Nitrile Butadiene Rubber. If it is hydrogenated, it becomes HNBR (Hydrogenated Nitrile Butadiene Rubber).

FKM and NBR are two commonly used elastomers for high-end sealing applications, and not without reason. Both materials are suitable for a wide range of applications. They offer excellent compression resistance and both are resistant to most oils and lubricants, especially petroleum-based lubricants. In addition, applications with moderate temperatures between -15° C and 110° C are suitable for both types, making both materials a very good choice for heavy industrial use.

WHICH SEAL IS OPTIMAL FOR YOUR APPLICATION?

Due to the wide range of available materials it is sometimes difficult to determine which seal is most suitable for your project. In many cases, a fairly simple assessment of the elasticity or tear resistance that your application requires is sufficient, but sometimes it is crucial to pay more attention to the choice of materials.

Due to the wide range of available materials it is sometimes difficult to determine which seal is most suitable for your project. In many cases, a fairly simple assessment of the elasticity or tear resistance that your application requires is sufficient, but sometimes it is crucial to pay more attention to the choice of materials.

Important circumstances to consider are:- Temperature of your application/environment

- Chemical resistance

Standard FKM connections can continuously seal at temperatures up to approximately 205° C. Standard NBR, on the other hand, is only effective for continuous sealing at temperatures up to 110° C. But at temperatures below -20° C, standard FKM seals are again less effective because they become relatively hard and inflexible. Special FKM joints can offer low temperature capacities of -40° C, but standard NBR works successfully at -35° C and even up to -55° C with a special composition.

CHEMICAL RESISTANCE

FKM has a wide range of chemical resistance, making it ideal for most applications with oils, fuels and mineral acids. FKM also offers excellent resistance to oxidation, ozone, exposure to UV radiation, weather and fungi. Although NBR also supports some of the same chemical resistances, it is much less universally resistant than its FKM counterpart, and is affected by weather and ozone exposure. But NBR has superior wear and tear resistance and is therefore better suited for heavier, industrial applications.

CHOICE OF SEALING MATERIAL

CHOICE OF SEALING MATERIAL

In short, consider the following conditions to get a good idea of which sealing material fits the best your application:- Fabrics in process and environment

- Required tear and abrasion resistance

- Temperature

- Chemical resistance

- Lifespan

80 GComment

-

Napa makes 2 that are the right size:

https://www.napaonline.com/en/p/NOS12736 Looks to be viton

https://www.napaonline.com/en/p/NOS12749 Looks to be buna

80 GComment

-

Thinking about this, with a double lip seal, do both lips actually make contact on the crankshaft? From my memory I would say no because the crankshaft in our engines is too short. There are triple lip seals available so maybe this could be an option!?

Not a triple lip, but the Timkin brand should be good quality, 70 durometer nitrile....

https://www.directpneumatics.com/290...x48x8-r2ls32-s

Wondering about the quality of some of these seals, could some be made in China and be a lesser quality? May be time to get one of the best quality.Last edited by bikerphil; 02-22-2024, 09:52 PM.2H7 (79) owned since '89

3H3 owned since '06

07 Triumph Tiger 1050

"If it ain't broke, modify it"

☮Comment

-

The entire seal is against the crankshaft, but the second lip may only protect the first from contamination.

Oil should not reach the second lip so it needs grease.

oringsandmore.com is out of virginia.

I'm curious about the napa Transfer Case Rear Output Shaft Seal

Spring Loaded, SKF Patented Bi-Directional Wave Seal, Positive Fluid Control,Chemical & Abrasion Resistant Rubber, Temps From -40 Deg F to 400 Deg F

https://www.napaonline.com/en/p/NOS12736

I may ask them to order it and look at it without buying it to see if it looks like it could work for this.

I am not buying any while my foot is dry...900+ mi

And, the right side seal is still available directional and installable without splitting cases.

https://www.partzilla.com/product/ya...eeb19b62f81350Last edited by speedlimit85; 02-23-2024, 12:59 PM.80 GComment

-

Right. No sleeve.

I may have happened upon a good installation by not letting the bike cool off. The seal before leaked in 30 mi so I did it again right away.

It went in clean and easy. These kind of seals seem more brittle but durable.

If I get a drop of oil on my toe, I'll let you know.80 GComment

-

OK, made some time this morning to re-do this seal. Removed Buna double lip and installed a Viton single lip. It can take higher temps and it's single lip like the original. I wrapped the crank end with black electrical tape to install. 36MM socket to gently tap in.

Comment

Comment