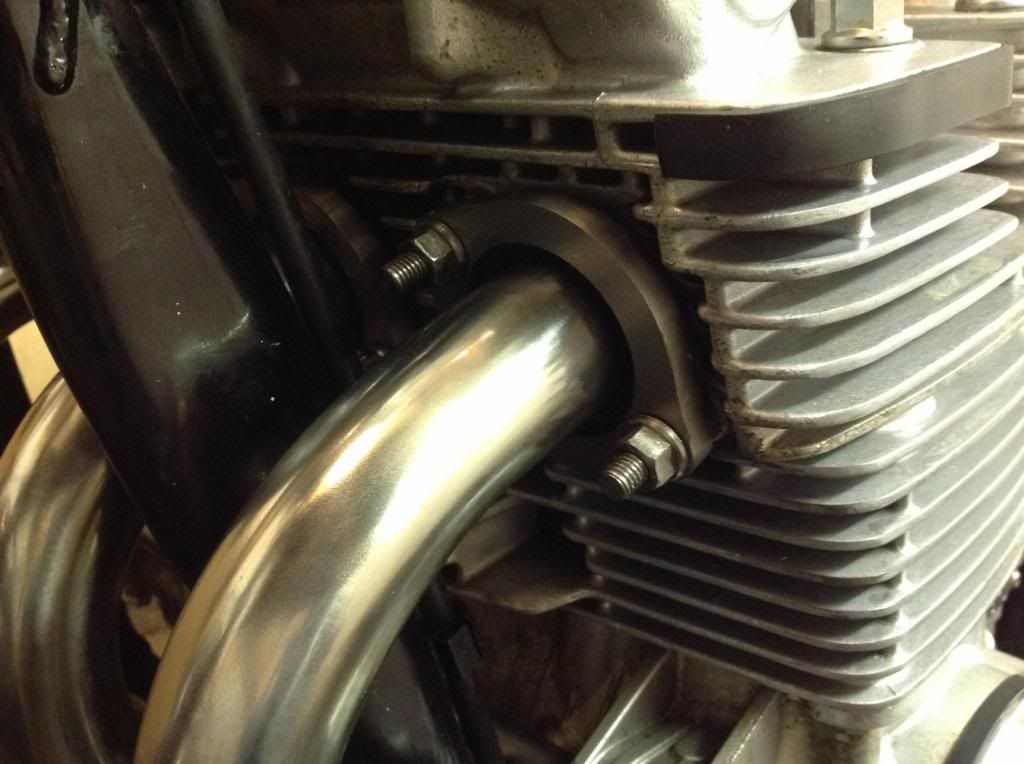

I know what you mean re appearance and there's no need to apologise for your attention to detail! Also it's an important point you make re corrosion of protruding threads and the use of acorn nuts. The corrosion thing isn't a problem in this case though as the studs, nuts and flanges are all titanium. I did want to leave a bit of margin because I replaced the OEM flange gaskets with copper ones which came with my stainless pipes and I wasn't sure how long the studs needed to be. In fact, they are 5mm longer than OEM because the bulge in the middle is 10mm, not 5mm.

I may get the hacksaw out but...that would mean removing them and I'm kind of all studded out mentally at the moment!

I may get the hacksaw out but...that would mean removing them and I'm kind of all studded out mentally at the moment!

.

.

Comment