Yeah, I don't think you're going to see a CPS or Hz below 200, and I suspect higher. If you only use one diode (for a half-wave output), that would cut it in half to 100, but would still exceed the capabilities of the meter. You would get a reading, but it wouldn't match the calibration/meter scale so you couldn't really tell what you have.

Somebody with an oscilloscope could quickly tell you what you have...

Somebody with an oscilloscope could quickly tell you what you have...

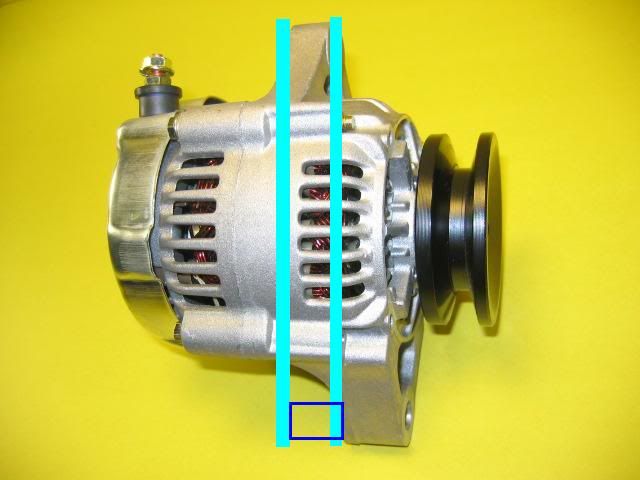

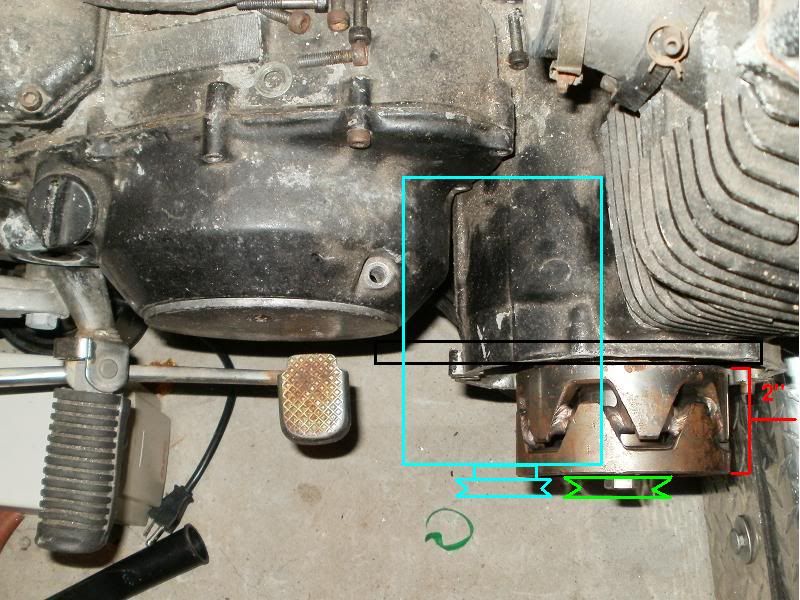

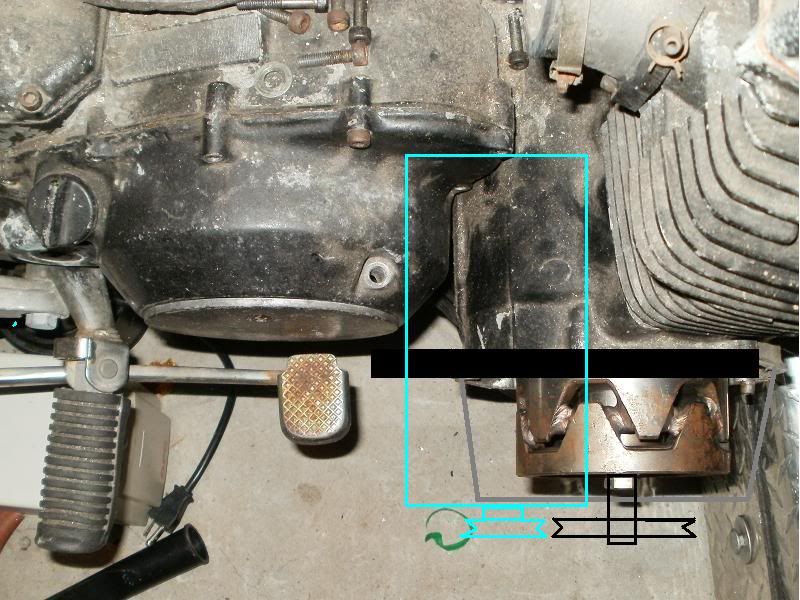

SO....it looks like the OEM Alt and Casing cover would still need to be removed, so as not damage them in case of returning to OEM, and being able to access the crankshaft/Rotor assembly to mount the extra ALT mounting bracket(s) as well as the crank pulley.

SO....it looks like the OEM Alt and Casing cover would still need to be removed, so as not damage them in case of returning to OEM, and being able to access the crankshaft/Rotor assembly to mount the extra ALT mounting bracket(s) as well as the crank pulley.

). A cogged belt would be best (low rotating mass, so it could take the rpms), no lube needed, only needs to be tight enough to keep the teeth engaged, and relatively commonly available (used in NASCAR, other racing). But not cheap; a drive system like this I expect would set you back at least $100, if not much more. These are also wider than a conventional belt drive, so now you're back to space considerations.

). A cogged belt would be best (low rotating mass, so it could take the rpms), no lube needed, only needs to be tight enough to keep the teeth engaged, and relatively commonly available (used in NASCAR, other racing). But not cheap; a drive system like this I expect would set you back at least $100, if not much more. These are also wider than a conventional belt drive, so now you're back to space considerations.

Comment