Right on, you got the frequency, Kenneth!

D'oh! I did not see the stator wires before but now that you mention them I sure do.That'll make it a lot easier to tap than pulling the diode bridge but you really, really, should find out what the two unmarked mystery terminals are supposed to do, don't guess. It could make things easier or prevent tears after doing a benchload of work.

The Yellow wire is 7V because it's tied to all the other phases. It sees half the voltage so it's 7V, not 14V. You can use the 7V relay for whatever you want, just make sure you put in a fuse because the O.E.M. relays are getting harder to find every year. You already have two White wires, one with a diode, in Godzilla's harness. You could put them both on the same phase leg and not upset the higher output alternator much or you could balance the load between two legs. You know how the guys in white coats did it when they designed the XS but it's up to you.

For reference: A couple of days ago I discovered that the XJ1100 does not use a headlight relay, it uses the Start button to make/break the headlight circuit. I included both XS1100 relays and the wire colors because you know someone is going to try this with a '78/'79 and wonder about the differences in the lighting circuit!

D'oh! I did not see the stator wires before but now that you mention them I sure do.That'll make it a lot easier to tap than pulling the diode bridge but you really, really, should find out what the two unmarked mystery terminals are supposed to do, don't guess. It could make things easier or prevent tears after doing a benchload of work.

The Yellow wire is 7V because it's tied to all the other phases. It sees half the voltage so it's 7V, not 14V. You can use the 7V relay for whatever you want, just make sure you put in a fuse because the O.E.M. relays are getting harder to find every year. You already have two White wires, one with a diode, in Godzilla's harness. You could put them both on the same phase leg and not upset the higher output alternator much or you could balance the load between two legs. You know how the guys in white coats did it when they designed the XS but it's up to you.

For reference: A couple of days ago I discovered that the XJ1100 does not use a headlight relay, it uses the Start button to make/break the headlight circuit. I included both XS1100 relays and the wire colors because you know someone is going to try this with a '78/'79 and wonder about the differences in the lighting circuit!

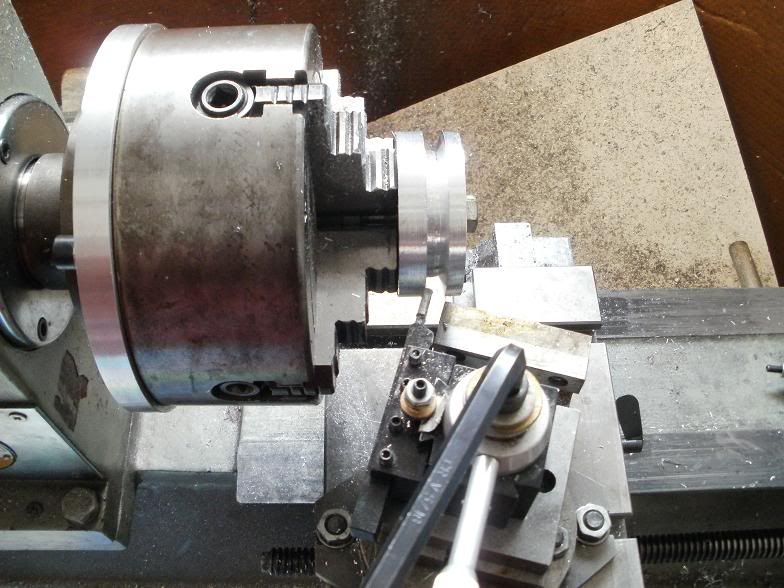

I had forgotten about the small incremental tool advance slide on my LATHE, and that I could ANGLE it to get the "V" shape!

I had forgotten about the small incremental tool advance slide on my LATHE, and that I could ANGLE it to get the "V" shape!

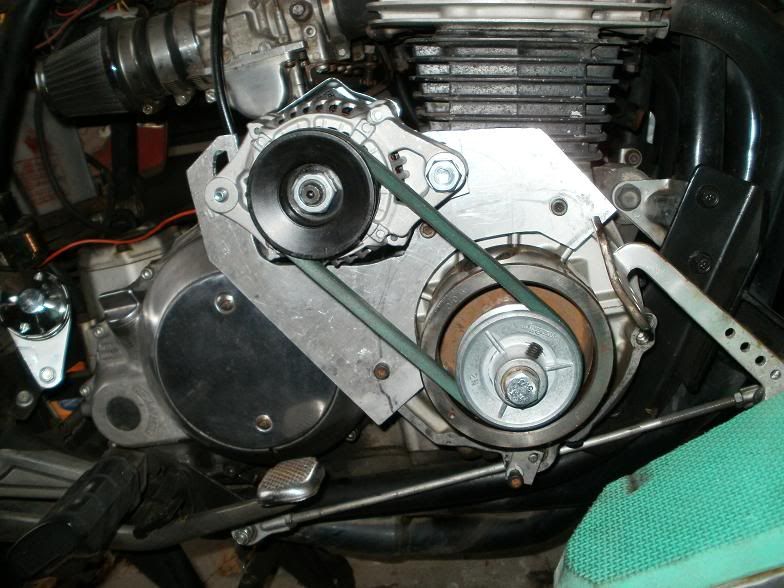

I used the OEM ALT Case cover as a template to draw on the plate the areas for cutout.

I used the OEM ALT Case cover as a template to draw on the plate the areas for cutout.

Comment