Leave it to the Airborne to come up with a great mod for an XS. Tadracer (101st) had an excellent modification for a cam chain tensioner in a previous post. Unfortunately it involved machining a block of aluminum. I kept looking at it and wondering how I (2/75th) was going to turn a piece of aluminum down to make my own housing. Then I stripped my tensioner locking bolt, and suddenly it hit me - I already had a housing.

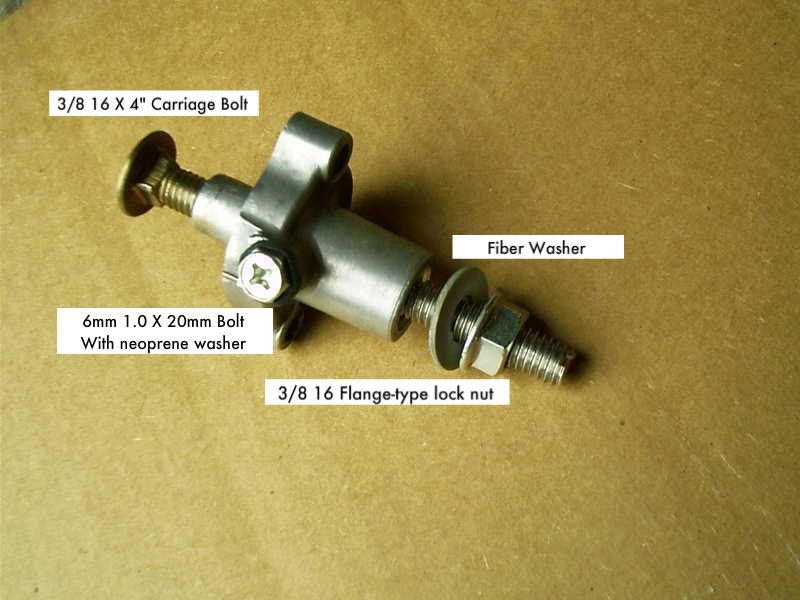

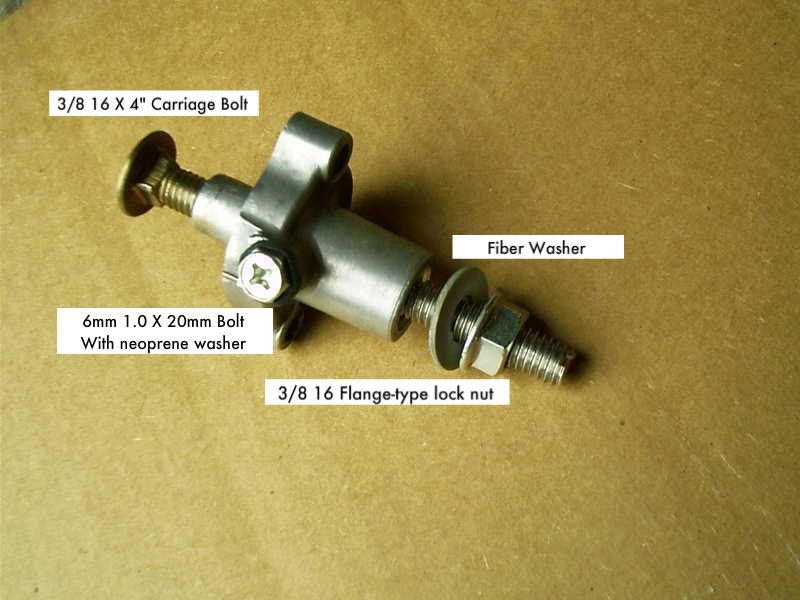

I took the existing tensioner, tapped the tensioner shaft tunnel and installed a 4" stainless steel carriage bolt with the face ground flat. The tunnel is the perfect size for a 3/8 16 tap with no drilling required. I know what your going to say - 'That ain't metric, you savage.' I looked high and low for a metric carriage bolt, but couldn't find one in the right size, so I just went with sae. My appologies. Make sure the tap you use has teeth that overhang the shaft such that you can run it all the way through - it's a deep tapping operation. I took one and ground the shaft down so that it would work.

I took a locking flange nut, held it with a deep socket, and ground the ridges off the face and installed with a fiber washer.

I tapped out the stripped locking bolt hole and installed a bolt with a neoprene washer. Filling it with JB Weld would work just as well, and the next time I have it off that's what I intend to do.

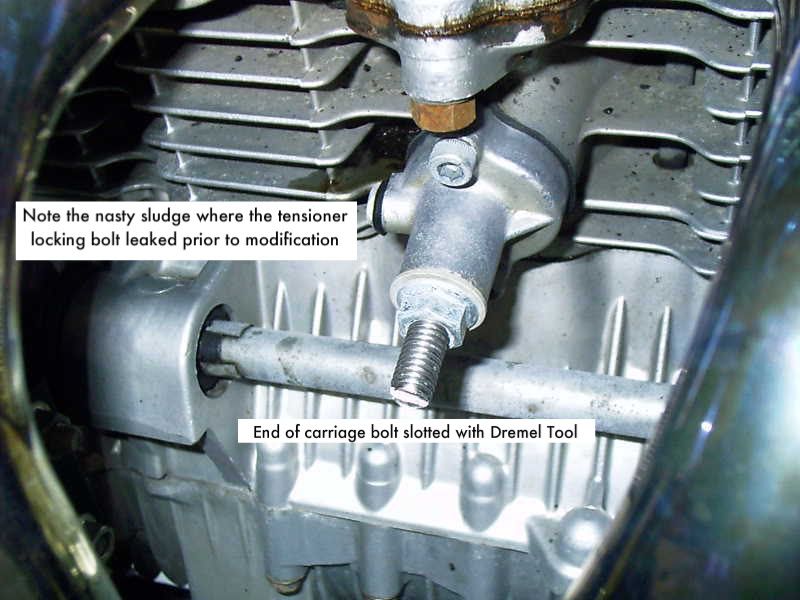

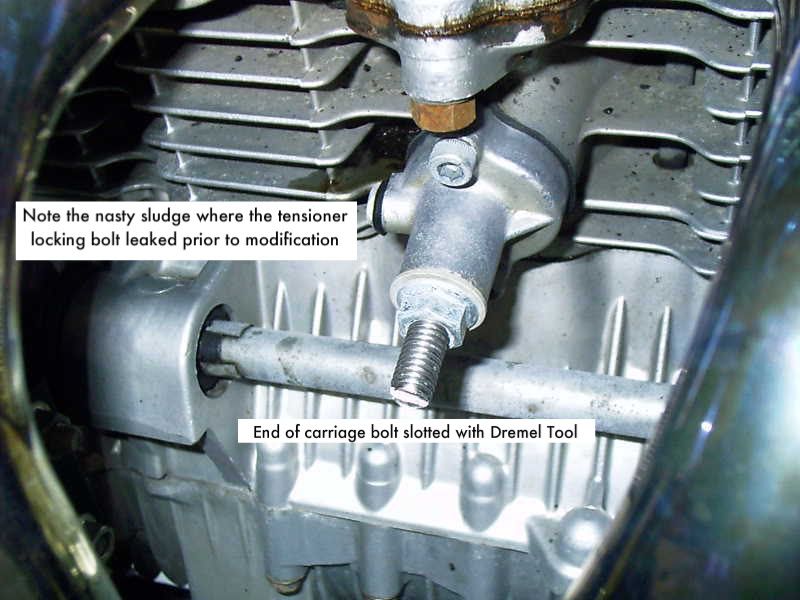

I cut a slot in the end of the carriage bolt to accomodate a flat-bladed screwdriver.

To tension the chain, set the timing plate to 'C', loosen the locking nut, turn the stem in hand tight, hold the stem with a screw driver to prevent it from turning and re-tighten the locking nut. Doesn't need to be too tight. If you're going to try this on a hot motor, I recommend using a screwdriver to adjust, turning with the shaft not the handle to avoid over tightening, and a crowfoot wrench for the locking bolt - unless you like muffler burns. Or just do what I do, and adjust it cold.

Originally I wrapped the threads with teflon tape to avoid any possibility of leaks. It made it too difficult to turn by hand, so I took it off and reassembled without it. I doesn't leak at all, so the teflon tape wasn't needed. You want the carriage bolt to turn easily so you can get the correct tension on it.

This mod works GREAT. It doesn't slip, and it doesn't leak. Total expense was about $6, not counting tools.

As there may be some legs reading this post, I better add some pics (that was for your amusement, Mike Giroir)

(that was for your amusement, Mike Giroir)

And here it is installed:

I took the existing tensioner, tapped the tensioner shaft tunnel and installed a 4" stainless steel carriage bolt with the face ground flat. The tunnel is the perfect size for a 3/8 16 tap with no drilling required. I know what your going to say - 'That ain't metric, you savage.' I looked high and low for a metric carriage bolt, but couldn't find one in the right size, so I just went with sae. My appologies. Make sure the tap you use has teeth that overhang the shaft such that you can run it all the way through - it's a deep tapping operation. I took one and ground the shaft down so that it would work.

I took a locking flange nut, held it with a deep socket, and ground the ridges off the face and installed with a fiber washer.

I tapped out the stripped locking bolt hole and installed a bolt with a neoprene washer. Filling it with JB Weld would work just as well, and the next time I have it off that's what I intend to do.

I cut a slot in the end of the carriage bolt to accomodate a flat-bladed screwdriver.

To tension the chain, set the timing plate to 'C', loosen the locking nut, turn the stem in hand tight, hold the stem with a screw driver to prevent it from turning and re-tighten the locking nut. Doesn't need to be too tight. If you're going to try this on a hot motor, I recommend using a screwdriver to adjust, turning with the shaft not the handle to avoid over tightening, and a crowfoot wrench for the locking bolt - unless you like muffler burns. Or just do what I do, and adjust it cold.

Originally I wrapped the threads with teflon tape to avoid any possibility of leaks. It made it too difficult to turn by hand, so I took it off and reassembled without it. I doesn't leak at all, so the teflon tape wasn't needed. You want the carriage bolt to turn easily so you can get the correct tension on it.

This mod works GREAT. It doesn't slip, and it doesn't leak. Total expense was about $6, not counting tools.

As there may be some legs reading this post, I better add some pics

(that was for your amusement, Mike Giroir)

(that was for your amusement, Mike Giroir)

And here it is installed:

), and no problems. When I adjusted it I just turned it in finger-tight. I think you would have a hard time over-tightening if you just use your finger tips. I was somewhat concerned that the metal against the teflon runner could cause some wear. I'm looking for a little plastic cap to put over the end of the carriage bolt just to satisfy my anal-retentive tendencies

), and no problems. When I adjusted it I just turned it in finger-tight. I think you would have a hard time over-tightening if you just use your finger tips. I was somewhat concerned that the metal against the teflon runner could cause some wear. I'm looking for a little plastic cap to put over the end of the carriage bolt just to satisfy my anal-retentive tendencies

Comment