The area of the bowl that surrounds the pin is close enough to the towers to prevent the pin from coming out.

stuck float pin/ Float pin tool

Collapse

X

-

-

Re: Question?

I cleaned another bike carb (small kawasaki?) that retained the pin with the sides of the bowl. Otherwise it slid back and forth.

Originally posted by mro

Would anything bad happen if the pins were "sloppy" in the post holes.

Wouldn't the bowl keep them from falling out???

mroSkids (Sid Hansen)

Down to one 1978 E. Stock air box with K&N filter, 81H pipes and carbs, 8500 feet elevation.Comment

-

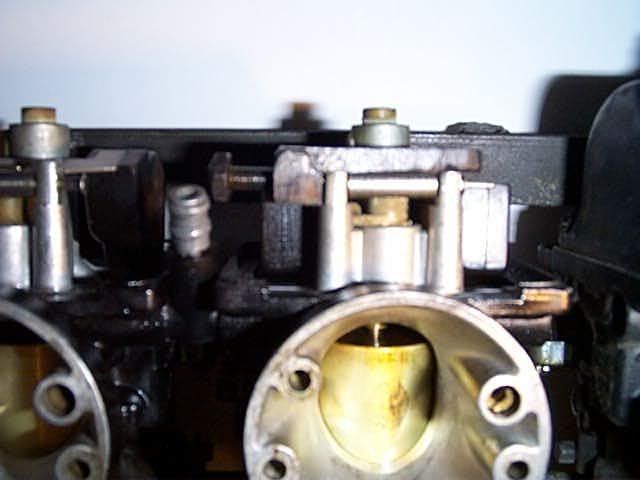

.. here ya go CUBuffs, the shiny new one on the left, i had just bought today from the national tool guy for about 15 bucks.

the one on the far right is the one i purched from the snap on guy over a year ago for too much money.

the one in the middle is the one you DON'T want, i bought it from the mack guy for about 15 bucks also, it has too much hammer force and it WILL break your carb!

.. i have bought tools that had the brand name Lisle on it from Sears, you might find this there for less money

Comment

-

Using the micrometer tonight on both an old style and a new style carb, I found that the posts are the same distance apart on both, so a "double-leg chain breaker-type" tool should work for all models. Rather than go in from the side, the tool could slip down on top of the posts. It would clear the float and pivot if the post support legs were 2mm long. The business end of the threaded pusher can be 2mm diameter, and it needs to sit 5mm to centreline below the top of the posts. I'll try to work up another drawing, this time to scale.Originally posted by GNEPIG

.. how about a support hook on the back side of both of the posts while using the short pressure bolt. if done this way this tool would be model specific unless the supports were made to be adjustable

Ken TalbotComment

-

-

"Another fine thread"

Ken, I note that for the screw in your recent drawing, you've switched to one with a fine thread. (no comment, just observation)

While perusing Harbor Fright for airhose fittings, found something interesting. (Well, actually, two things interesting. They currently have those little plastic, stackable, storage bins/drawers on sale, 20 fer $6. Bought two sets)

Anyway... always on the lookout to acquire another bad habit, I was looking at their vice's(vises), in regards to our current exercise. I have two problems with the current design proposed. The main one being... (sure, I can tap a hole), I don't have the equipment to machine a device such as this, and I can think of nothing lying around that I could modify to a similar, and exact shape and function. Second, (and this is just my vast expertise as a non-engineer) moving the device to the top, though easier to construct, is a more risky venture. Attacking from the side put the whole of the stress on the thick part of the post. Here, the stress is placed at the tops of the posts, and when force is applied, the posts would tip and snap at their weakest point, that being where they have the least material... the area where the hole for the float pin is drilled. I see either the pin moving out to the left, or the post tops moving off to the right. Half of the force used here is applied to the pin, and the other half is applied to the posts, which is the cause of the snapping.

To overcome this, ideally force must be applied to the pin only, and not transferred to the post that it's stuck in. The problem as I see it, is in stopping the force from being applied to one post but not the other. Or in applying the force to the tips of the posts, but not the rest of the length of the posts. Hence, my study of vises. Initially, I thought of those welder's visegrips, those ones with the clamping bar welded to the jaws. But, they only come in large sizes with too large of clamping bar lengths. Sure, they could be cut shorter, but I was concerned about an uneven pressure. Harbor Fright has many sizes of small vices, like around 4 or 6 inches long, that may be adaptable.

The idea would be, like in your drawing to attack the problem from the top. One would pinch BOTH posts with the vice, and them tap the pin out with a center punch or something. This setup would not be held in a larger vise or anything, but would be free, both carb and vise, to move around the work bench to absorb the shock. I don't want the vise to remain stationary, nor the bank of carbs, but for both to move together if need be.

Advantages: Both posts remain fixed together, no possability of one being forced closer or further away from the other(snapping) The force applied to the pin, for the most part, is only applied to the pin. Any force that was applied to the post would be absorbed by BOTH posts, or the carb body as a whole. Whether the vise should be applied only to the posts above the pin hole, or to the whole tapered section of the posts, may or may not matter, the consideration there being not to compress the area where the pin resides, making it even tougher to get out.

Thoughts?"Damn it Jim, I'm a doctor, not a mechanic!' ('Bones' McCoy)Comment

-

'I flush, but still get Floaters!"

I keep forgetting that the whole idea is to remove the pin to remove the float! The vise cannot be applied below the pin hole, as the float is in the way. Applied to the tips, then.Whether the vise should be applied only to the posts above the pin hole, or to the whole tapered section of the posts"Damn it Jim, I'm a doctor, not a mechanic!' ('Bones' McCoy)Comment

-

Re: "Another fine thread"

I was thinking of starting with a piece of something like 3/8" thick aluminum plate, 10mm by 40mm. A hacksaw and/or Dremel would look after the major removal , and a file could look after the rest. It also came to me that by coming at it from the top, there could be a suppport on each side of each post because there would be no interference from the pivot or float this way. This would be even easier to machine. Stay tuned for another sketch.. Hey, now we're having fun!!Originally posted by prometheus578

The main one being... (sure, I can tap a hole), I don't have the equipment to machine a device such as this, and I can think of nothing lying around that I could modify to a similar, and exact shape and function. Ken Talbot

Ken TalbotComment

-

Hhhmmm... I don't have any aluminum plate lying about. But I do have a stainless steel plate in my head, which they remove from time to time to rearrange the rocks in there. My tool would be a lot more shiney than yours. I like shiney things. And tapping threads in stainless would be more accurate... I wouldn't want to be accused of having a screw loose now, would I?"Damn it Jim, I'm a doctor, not a mechanic!' ('Bones' McCoy)Comment

-

Here we go again - support on both sides of the posts, approaching from the top. Still in concept stage as the screw detail needs some work when I can get onto my better drawing programme at home...

Ken Talbot

Ken TalbotComment

-

-

.. the force that your push bolt will exert against the end of your pin will go to the left, the force that your holder will exert on the top of your posts (the equal and opposite reaction) will go right.

so what if you made the bump on the far left out side(of your tool, in your picture) extend all the way down to the base of the left post and put a hole in it just larger than the head of the pin. this would spread the force over a greater area insted of just on top of the posts where it is known to be the weak spots.. two weak spots are better than one but it is still weak

.. use the force LukeComment

-

In shop today, didn't feel like working so decided to remove pins

out of 80LG. Carbs appear to have never been taken apart and

unlike my 80G these puppies are aluminum and stuck tight. Took YOUR IDEA and made this. works well but not as pretty as your design.

Comment

-

mro........way to go!!!!

You got it right on the money. I was going to post that we still had the problem of unrestrained pressure on the carb posts because of the position of the leg that held the turnscrew. Putting it up against the post instead of being offset IS the answer to the problem.

A little refinement and we got a new tool. Royalties to be divided equally RIGHT!!!

Comment

-

Wet Rock

"A little refinement and we got a new tool. Royalties to be divided equally RIGHT!!! "

Sounds good to me.

about $0.19 for material

weld/drill/file and tap and blamo, the XS super pin remover.

should be millionaires after we sell only about 20 million of em!!!

course we would have to split w/GNEPIG/Ken/prom and skids too.

Guess you could call it the:

Gnkeprowetskid-mo pin remover tool.

mro

btw

forgot to mention that the tool needed to be "hardened” too. Otherwise little "Punch" (end of screw) bendsComment

Comment