Final Drive overheating

Collapse

X

-

XS1100F 1980 European model. Standard. Dyna coils. Iridium plugs. XS750 final drive (sometimes). Micron fork brace. Progressive front springs. Geezer regulator/rectifier. Stainless 4 into 2 exhaust. Auto CCT (Venturer 1300) SOLD. New project now on the go. 1980 European model. -

X2 Espescially the second paragraph so fer "Chrissake" as Fred would say enough about the torque. Your cages lug nuts spec at 100 ft. lbs. and a girl can change a tire so 108 ft. lbs. on the BIG axle nut is recommended so a heavy hand doesn't strip the threads off of the axle.The burned lube is not good, particularly if there was enough in there (and 10 oz should be enough). The metal on the drain plug isn't good either. I'd pull the F/D off the swingarm and check the gear lash as per the manual, maybe even pull the ring gear out of the housing to check how smooth the ring and pinion bearings spin. I'd say there's a very good chance one or both of those bearings are failing. If that's the case, you'll need to replace the final drive; you don't want that seizing on you while riding, at anything above much more than 10-15 mph that's a good way to go down.

The axle torque should have nothing to do with this; none of the torque is transferred to the bearings, all of it is taken by solid spacers if they're all in place. There is one spacer that can fall or be knocked out; located in the wheel on the drive side, you should have a small short spacer (part #15 on the parts diagram) protruding from the grease seal on the drive-side wheel bearing. If that's missing and you installed the wheel and ran the bike, the axle torque would be transferred to the ring gear bearing and it has failed. Time for a replacement FD.....

Also, gargoyle_house, if your present FD is toast you may want to check into the FD 750/850 Swap Mod depending on what style of riding you primarily do, as they are a higher gear ratio which results in lower rpms at highway speeds.

Here's a link:

1980 XS1100G "Dolly G" Full Dresser (with a coat of many colors )

)

1979 XS1100SF (stock-euro mods planned)

1984 XV700L Virago (to be hot-modded)

1983 XJ750MK Midnight Maxim (semi-restored DD)

1977 XS650D ( patiently awaiting resto)

Sometimes it takes a whole tank of gas before you can think straight.

Comment

-

That spacer has a lip on it's inner edge, such that it will not come out unless the seal comes out.There is one spacer that can fall or be knocked out; located in the wheel on the drive side, you should have a small short spacer (part #15 on the parts diagram) protruding from the grease seal on the drive-side wheel bearing. If that's missing and you installed the wheel and ran the bike, the axle torque would be transferred to the ring gear bearing and it has failed. Time for a replacement FD.....

The spacer/ dust collar on the other side is easy to drop out, but makes it apparant that something is missing when you go to put the axle in.

I'm betting on the FD being bad. CZComment

-

replaced final drive, installed wheel, binding as I tighten....

So guys, I've 1) rebuilt the rear brake master cylinder, it was rusty, not working well, and probably was not binding (works great now)

and then 2) bought a used final drive, in great condition and installed it. Greased the splines well, reassembled -- and started to tighten the axle nut. Wheel spins great until some pressure is applied (like about 30 lbs) and it starts to bind -- so I stopped. When nut is loosened, wheel spins fine. There's no 'wobble' on bearings -- and when I spun them with my fingers before reassembling them, they seemed smooth. But, I'm guessing with a new final drive, a correct assembly with all the parts-- it's got to be the bearings.

I tried to see what 'part #15' was -- but couldn't (see earlier posts) but I doubt I lost any spacer from the wheel -- the gasket (rubber) on the drive side of the wheel is in place...and I understand the spacer is behind the gasket. Before I tear the wheel bearings down I'm ordering some from a guy on here who posted that he has them....

Will take pictures tonight and post them -- maybe I'm doing something wrong -- but doubt it. I'm pretty meticulous about parts when I tear something down...

Thanks for any new advice...Comment

-

HAD them, I'm afraid. I just PM'd you. Please see my recent post about this. I think I can guess what your vote in the poll will be

By the way, the best way to examine bearings properly is to degrease them entirely by immersing them in gasoline or solvent (don't smoke at the same time and watch for sparks off battery chargers etc). Then, spin the bearings and listen/feel. I've found that seemingly good bearings can be worn, with pitted races, noisy and a crunchy feel to them.XS1100F 1980 European model. Standard. Dyna coils. Iridium plugs. XS750 final drive (sometimes). Micron fork brace. Progressive front springs. Geezer regulator/rectifier. Stainless 4 into 2 exhaust. Auto CCT (Venturer 1300) SOLD. New project now on the go. 1980 European model.Comment

-

I disagree with that statement James. Any solvent on a bearing isn't a good thing simply because solvents break down grease and it's virtually impossible to get all the solvent out of the bearing therefore defeating the purpose of the grease.

I don't know how much mechanical experience you might have but if you have ever taken a hub on a vehicle apart and a slimey gooey substance that should be bearing grease drips out of the hub that is a result of bearings and/or a hub that has been cleaned with solvents and the residue broke down the grease.

Not saying that just to argue, 30+ years of experience being in the automotive service field.Greg

Everybody is a genius. But if you judge a fish by its ability to climb a tree, it will live its whole life believing that it is stupid.”

― Albert Einstein

80 SG Ol' Okie;79 engine & carbs w/pods, 45 pilots, 140 mains, Custom Mac 4 into 2 exhaust, ACCT,XS850 final drive,110/90/19 front tire,TKat fork brace, XS750 140 MPH speedometer, Vetter IV fairing, aftermarket hard bags and trunk, LG high back seat, XJ rear shocks.

The list changes.

Comment

-

Greg, when I got into the mechanic trade (before switching to electrical), that's how I was taught to clean bearings; flush them out with solvent. You do have to make sure you get them perfectly dry before repacking them, but I've never had any issues by doing this and still do it to this day. Now, I don't don't know about gasoline; that does leave 'stuff' behind when it dries and I was told specifically not to use gas and I never have.Fast, Cheap, Reliable... Pick any two

'78E original owner - resto project

'78E ???? owner - Modder project FJ forks, 4-piston calipers F/R, 160/80-16 rear tire

'82 XJ rebuild project

'80SG restified, red SOLD

'79F parts...

'81H more parts...

Other current bikes:

'93 XL1200 Anniversary Sportster 85RWHP

'86 XL883/1200 Chopper

'82 XL1000 w/1450cc Buell, Baker 6-speed, in-progress project

Cage: '13 Mustang GT/CS with a few 'custom' touches

Yep, can't leave nuthin' alone...Comment

-

I usually use aerosol cans of brake and clutch cleaner, with the bearing in a small plastic container. I haven't really encountered a problem with any solvent remaining in the bearing though. I just let the solvent evaporate and spin the bearing to a different position, leave it again and so on. Or put the bearing on a radiator to warm up. I suspect that, done in a hurry (eg by someone in a garage, where time=money), there could be residue left in there and form the goo you mentioned but, done at home by an enthusiast, there really is not a problem if the bearing is left long enough afterwards.XS1100F 1980 European model. Standard. Dyna coils. Iridium plugs. XS750 final drive (sometimes). Micron fork brace. Progressive front springs. Geezer regulator/rectifier. Stainless 4 into 2 exhaust. Auto CCT (Venturer 1300) SOLD. New project now on the go. 1980 European model.Comment

-

Opinions vary but the important part is the person doing the work. Brake and some other cleaners typically evaporate quick but if you use a carburator cleaner some of them do not dry well and leave residue. If you do not dry it out you get the runny mess. The other issue with solvents is they liquify all grease but at times you have material that forms like a crust that a simple spray or two will not clear you have to work the bearing. When you clean it, its best to make sure it is clear of the crusty residue and any goop. Most times the blame is put on what was used to clean rather than the true issue of the person just not cleaning and drying properly before reaplying grease. The important part is make sure the bearing is clear and dry. I prefeer a brake cleaner for final cleaning but have used a mix of detergent oil and gas to soak parts in before final cleaning.

As far as the bind you may want to just take the brake caliper off and check the wheel to make sure the bind is not in the brakes alignment with the disk. You may be fighting the wrong issue.To fix the problem one should not make more assumptions than the minimum needed.

Rodan

https://www.youtube.com/watch?v=khm6...liHntN91DHjHiS

1980 G Silverbird

Original Yamaha Fairfing and Bags

1198 Overbore kit

Grizzly 660 ACCT

Barnett Clutch Springs

R1 Clutch Fiber Plates

122.5 Main Jets

ACCT Mod

Mac 4-2 Flare Tips

Antivibe Bar ends

Rear trunk add-on

http://s1184.photobucket.com/albums/z329/viperron1/

http://s1184.photobucket.com/albums/z329/viperron1/Comment

-

Now what?

So guys, I've pulled the entire wheel off, removed the bearings, wiped them clean, rolled them with my fingers as much as I could and they were in great shape -- not a pit, not a crunch, not a shimmy. The rear brake doesn't bind at all (works great actually) now that it's rebuilt. Put the bearings back in -- didn't drop a part, and when the castle nut is torqued to anything over about 45 lbs the wheel starts to seize -- at 70 lbs it's hardly movable. It's not the brakes (can push the pads back so they don't even touch the disk, no problem), and I'm adding pics of the installed wheel--the right side as the spacer between the caliper and the plate, and yes, I had the pinch bolt loose, oh so loose, when I torqued the nut on the left. The picture of the left shows the new (reused) final drive installed with the washer and the castle nut. There's a clearance between the dust cover and the FD (can slide paper between them, all around, so no binding there).

The sleeve inside the LHS bearing slides freely when not assembled -- it drops out if you leave it there, so no binding there. The spacer inside the wheel is installed -- the bearings were tapped into place with care -- so I'm truly at a loss.

I hate to fix something that's not broken -- like, bearings that run smooth. But I can't find anyone with this problem. Could the sleeves inside the bearings have 'flared' a bit (like a very small bit) that allows the spacers to move just a few mm closer and so the torque is tightening the sleeves on the bearings? what else can rub? The large rubber ring between the wheel and the FD moves with the wheel/FD so it's can't be the thing that ground down.

I love this bike and can't stand that I can't ride it....

Last edited by gargoyle_house; 04-08-2012, 09:52 AM.Comment

-

Well I was taught 35 years ago (and I am still in the trade) I was told NOT to use solvent and was shown why as I explained. It seems unnecessary to clean the grease out anyway. If the bearing is good so is the grease.Greg, when I got into the mechanic trade (before switching to electrical), that's how I was taught to clean bearings; flush them out with solvent. You do have to make sure you get them perfectly dry before repacking them, but I've never had any issues by doing this and still do it to this day. Now, I don't don't know about gasoline; that does leave 'stuff' behind when it dries and I was told specifically not to use gas and I never have.

I'll just wipe them off and repack.Greg

Everybody is a genius. But if you judge a fish by its ability to climb a tree, it will live its whole life believing that it is stupid.”

― Albert Einstein

80 SG Ol' Okie;79 engine & carbs w/pods, 45 pilots, 140 mains, Custom Mac 4 into 2 exhaust, ACCT,XS850 final drive,110/90/19 front tire,TKat fork brace, XS750 140 MPH speedometer, Vetter IV fairing, aftermarket hard bags and trunk, LG high back seat, XJ rear shocks.

The list changes.

Comment

-

Is the caliper anchor bracket on the stop knob (for lack of a better description) on the swingarm slid in properly?So guys, I've pulled the entire wheel off, removed the bearings, wiped them clean, rolled them with my fingers as much as I could and they were in great shape -- not a pit, not a crunch, not a shimmy. The rear brake doesn't bind at all (works great actually) now that it's rebuilt. Put the bearings back in -- didn't drop a part, and when the castle nut is torqued to anything over about 45 lbs the wheel starts to seize -- at 70 lbs it's hardly movable. It's not the brakes (can push the pads back so they don't even touch the disk, no problem), and I'm adding pics of the installed wheel--the right side as the spacer between the caliper and the plate, and yes, I had the pinch bolt loose, oh so loose, when I torqued the nut on the left. The picture of the left shows the new (reused) final drive installed with the washer and the castle nut. There's a clearance between the dust cover and the FD (can slide paper between them, all around, so no binding there).

The sleeve inside the LHS bearing slides freely when not assembled -- it drops out if you leave it there, so no binding there. The spacer inside the wheel is installed -- the bearings were tapped into place with care -- so I'm truly at a loss.

I hate to fix something that's not broken -- like, bearings that run smooth. But I can't find anyone with this problem. Could the sleeves inside the bearings have 'flared' a bit (like a very small bit) that allows the spacers to move just a few mm closer and so the torque is tightening the sleeves on the bearings? what else can rub? The large rubber ring between the wheel and the FD moves with the wheel/FD so it's can't be the thing that ground down.

I love this bike and can't stand that I can't ride it....

https://picasaweb.google.com/lh/phot...eat=directlinkGreg

Everybody is a genius. But if you judge a fish by its ability to climb a tree, it will live its whole life believing that it is stupid.”

― Albert Einstein

80 SG Ol' Okie;79 engine & carbs w/pods, 45 pilots, 140 mains, Custom Mac 4 into 2 exhaust, ACCT,XS850 final drive,110/90/19 front tire,TKat fork brace, XS750 140 MPH speedometer, Vetter IV fairing, aftermarket hard bags and trunk, LG high back seat, XJ rear shocks.

The list changes.

Comment

-

Some closer more detailed pics would help a lot.Nathan

KD9ARL

μολὼν λαβέ

1978 XS1100E

K&N Filter

#45 pilot Jet, #137.5 Main Jet

OEM Exhaust

ATK Fork Brace

LED Dash lights

Ammeter, Oil Pressure, Oil Temp, and Volt Meters

Green Monster Coils

SS Brake Lines

Vision 550 Auto Tensioner

In any moment of decision the best thing you can do is the right thing, the next best thing is the wrong thing, and the worst thing you can do is nothing.

Theodore RooseveltComment

-

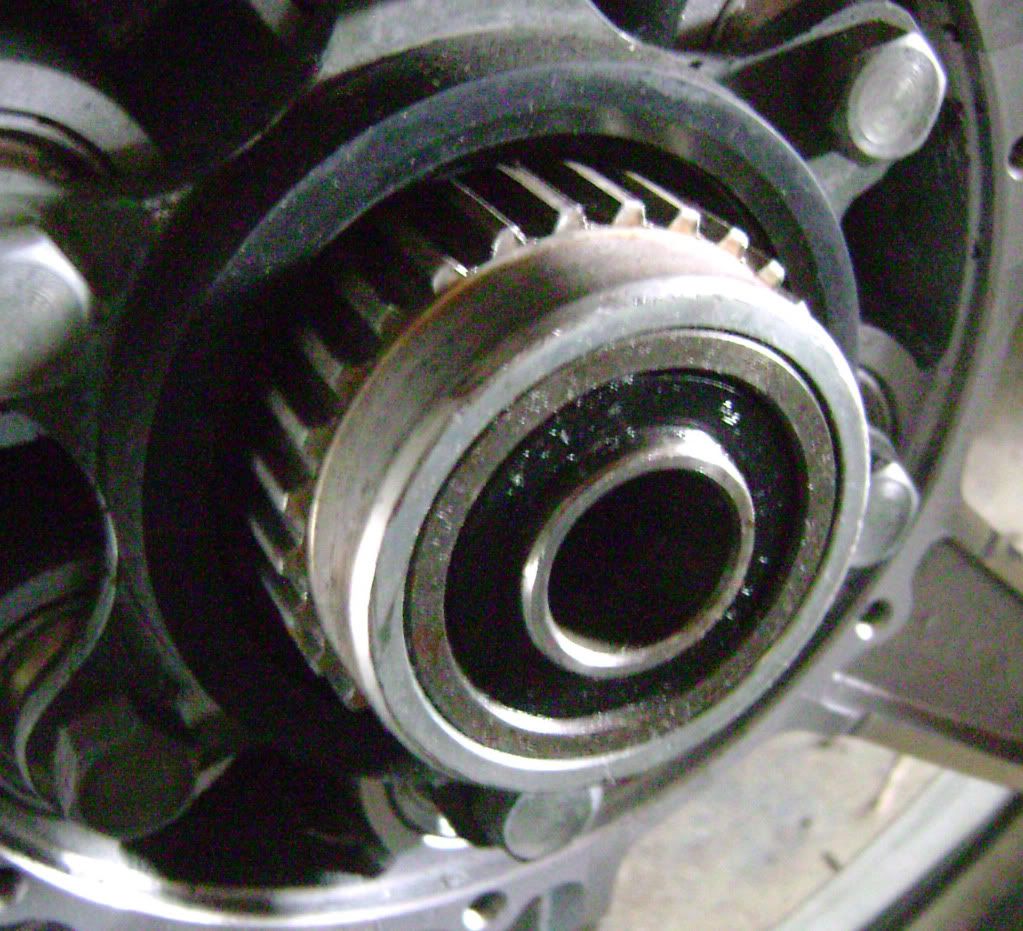

Here's a pic of the drive-side hub.....

You can see the small spacer sticking out of the seal. If that's missing, that's your problem. It should be protruding above the seal about .130", give or take a few .001". If that number is less by much, that's a problem. Also note that the splined drive hub is flush with the wheel hub; if that's out past the wheel hub any, that could be the problem. Make sure the large spline seal is fully seated against the drive hub.

This almost can't be a bearing problem; you've got something either mis-installed, a wrong part, or a part missing. The clearance between the FD and the plastic 'shield' on the wheel should be 1/16" or more. If you're seeing less, the wheel is going too far into the FD.

The only other thing I could think it might be (but this wouldn't have caused a drive failure) would be if the brake side bearing seal isn't fully seated you could have the dust seal on the spacer dragging on the seal, but this should be fairly obvious by examining the seal/spacer.Last edited by crazy steve; 04-08-2012, 12:30 PM.Fast, Cheap, Reliable... Pick any two

'78E original owner - resto project

'78E ???? owner - Modder project FJ forks, 4-piston calipers F/R, 160/80-16 rear tire

'82 XJ rebuild project

'80SG restified, red SOLD

'79F parts...

'81H more parts...

Other current bikes:

'93 XL1200 Anniversary Sportster 85RWHP

'86 XL883/1200 Chopper

'82 XL1000 w/1450cc Buell, Baker 6-speed, in-progress project

Cage: '13 Mustang GT/CS with a few 'custom' touches

Yep, can't leave nuthin' alone...Comment

-

You made me curious when you posted that Steve. I hav 2 rear wheels in the garage so I went out and checked and I can't MAKE that spacer come out. It seems to be a part of the bearing. Greg

Greg

Everybody is a genius. But if you judge a fish by its ability to climb a tree, it will live its whole life believing that it is stupid.”

― Albert Einstein

80 SG Ol' Okie;79 engine & carbs w/pods, 45 pilots, 140 mains, Custom Mac 4 into 2 exhaust, ACCT,XS850 final drive,110/90/19 front tire,TKat fork brace, XS750 140 MPH speedometer, Vetter IV fairing, aftermarket hard bags and trunk, LG high back seat, XJ rear shocks.

The list changes.

Comment

Comment