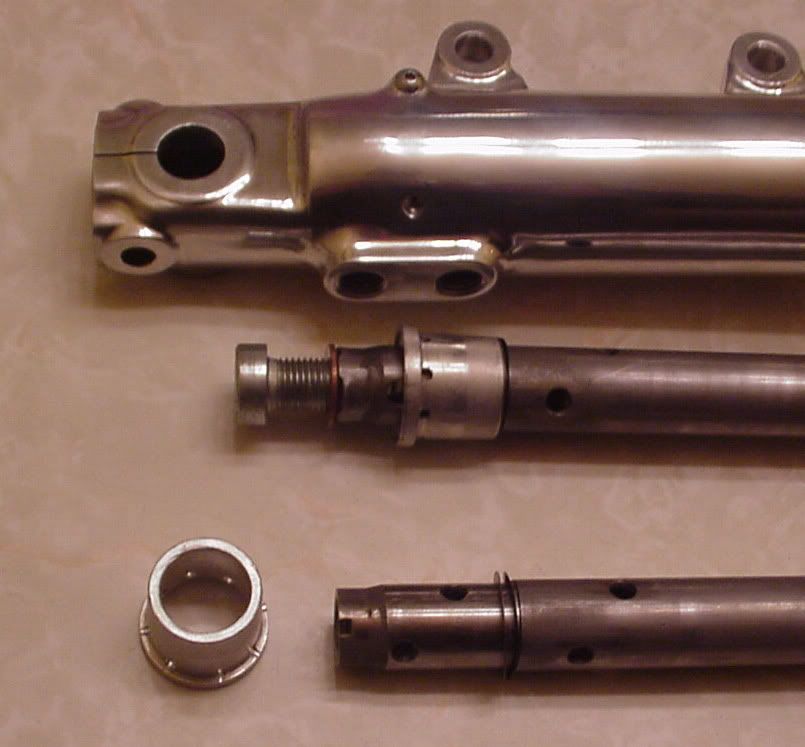

I have access to some larger tools, my neighbor seems to have everything and doesn't mind me borrowing things. That screw was all the way in, I had no idea that I had to remove it first. Just glad it didn't break, should be reusable...

That screw was all the way in, I had no idea that I had to remove it first. Just glad it didn't break, should be reusable...

That screw was all the way in, I had no idea that I had to remove it first. Just glad it didn't break, should be reusable...

That screw was all the way in, I had no idea that I had to remove it first. Just glad it didn't break, should be reusable...

Comment