A word of WARNING

Great mod. However, a word of warning to those who are going to do it. There is a VERY fine line between too tight and too loose with manual tensioners. Too loose and the cam chain will jump and bend all/half of your valves. Too tight and you will drastically shorted the life of your cam chain, which if it breaks, you will bend all your valves. Not to mention that if it breaks and binds up the crank, which is highly probable, it will lock up the bike while you are riding it.

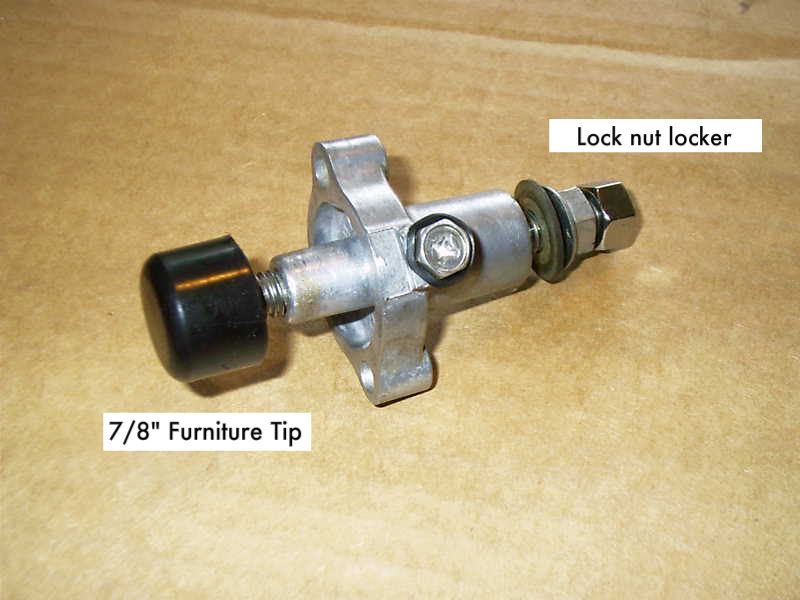

If you are really worried about the spring being old, a new one is under $4 from bikebandit. Or you could do like I do and stretch the one you have out a little. If your plunger is worn, it is only $28. Then again, I bet you could get a good completer unit off of ebay for under $10.

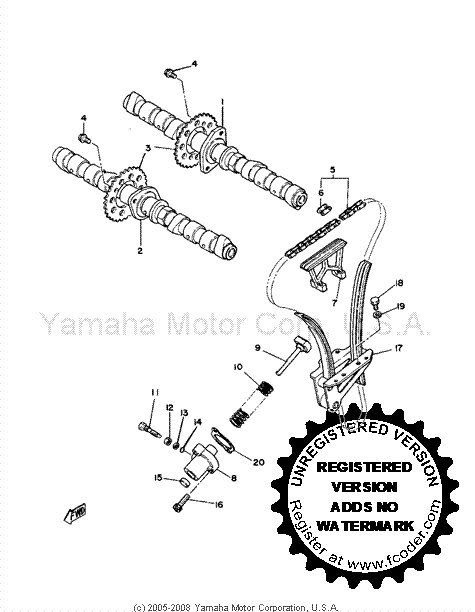

I only bring all this up because it was a huge debate that I started over at the KZrider forum. Allegedly, the kz's which have the same type of tensioner are notorious for getting sloppy and jumping the cam chain. Personally, I believe it is due not performing the regular tensioner maintenance. It is much more crucial on the kz's due to their ridiculous cam chain setup that has tons of rollers and do-dads, all of which wear, and create slop in the cam chain (as seen below).

Anyways, you have been warned

Great mod. However, a word of warning to those who are going to do it. There is a VERY fine line between too tight and too loose with manual tensioners. Too loose and the cam chain will jump and bend all/half of your valves. Too tight and you will drastically shorted the life of your cam chain, which if it breaks, you will bend all your valves. Not to mention that if it breaks and binds up the crank, which is highly probable, it will lock up the bike while you are riding it.

If you are really worried about the spring being old, a new one is under $4 from bikebandit. Or you could do like I do and stretch the one you have out a little. If your plunger is worn, it is only $28. Then again, I bet you could get a good completer unit off of ebay for under $10.

I only bring all this up because it was a huge debate that I started over at the KZrider forum. Allegedly, the kz's which have the same type of tensioner are notorious for getting sloppy and jumping the cam chain. Personally, I believe it is due not performing the regular tensioner maintenance. It is much more crucial on the kz's due to their ridiculous cam chain setup that has tons of rollers and do-dads, all of which wear, and create slop in the cam chain (as seen below).

Anyways, you have been warned

)

)

...

...

on your chirp dampener tensioner plunger....BUT.....

on your chirp dampener tensioner plunger....BUT.....

Comment