I need input on a few things. First of all, I need a gear cutting specialist if one exists on the forum. Then want to know if anyone has widened the swing-arm pivot points on the xs11? I plan on designing a gear and spacer that will set the middle-drive out 35mm so I can put at least a 180-200 tire on the back.

begging new mod, need input

Collapse

X

-

I don't know if it could handle the torque of the 11, but I have simply welded another collar onto the existing ones for hydraulic gate operators to extend the collar. Perhaps you could cut one off a sacrificial unit and weld it to that one?

I'd be interested in seeing that, too. It seems to me the bike would handle even smoother with nice new fat modern radials on it.80 XS1100SG

81 XS400SH

Some men miss opportunity because it is dressed in overalls and looks like work. - Thomas Edison

A Few Animations I've MadeComment

-

Hi xschop

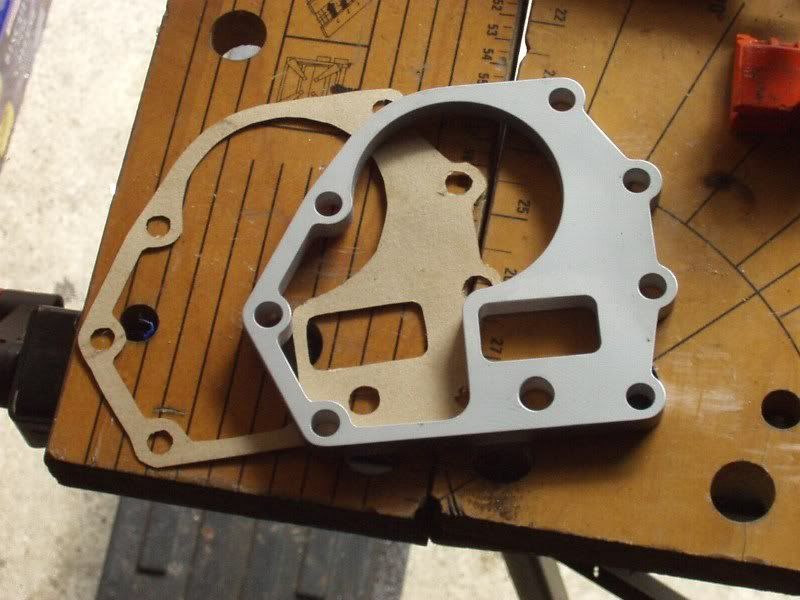

Do you mean like this:

I had it done using a thick slice off another and welded it on using the shaft to keep things in line. BUT even that didn't keep true enough and there was a very slight kink to it - just enough to cause it to rub. So I binned that idea.

I did look into get it remade but the splines are wire cut and very expensive to do.

Good luck.

Mike FMike Farnworth

XS1100 E & XS1100 Sport ProjectComment

-

Well, you thought of it first anyway!

Did you make a spacer for the middle drive,and how thick? I thought of another way to make a drive-coupler spacer last night. It would be a better idea because you wouldn't have to split the cases, Just install between the middle driven gear and shaft! Did you weld the machined part of the donor part to machined part of the driven gear? That should have turned out true, but welding is strange science...thanks for the pic....chopMDRNF

79F.....Not Stock

80G......Not Stock Either....In the worksComment

-

chop,

If you used the shaft, and had a "hard weld" built up on the outside, you could then turn it back down on a lathe. That would keep it true, and usable.

RayRay Matteis

KE6NHG

XS1100 E '78 (winter project)

XS1100 SF Bob Jones worked on it!Comment

-

Hard Weld?

Yes, I have decided to extend the shaft instead by 35mm.NO SPLTTING CASES!!! How can it be done correctly? Figure I need to cut one 35mm and fuse it to the next... MDRNF

MDRNF

79F.....Not Stock

80G......Not Stock Either....In the worksComment

-

Chop maybe it's possible to simply shim the drive unit out further with steel spacers and longer bolts, there's 7 of them, but the drive unit would need sealing on the engine side to keep the pinions in oil, even if the oil-fed drive unit bearings were replaced with sealed bearings,(although the stock left hand bearing is a thrust bearing) but there's still gonna be big torque/centrifugal forces coming from the pinion/bevel area, the spacer setup would need to be very solid, not 100% sure, but I think one of the trike guys on this site did extend the spline shaft by welding.

Chop maybe it's possible to simply shim the drive unit out further with steel spacers and longer bolts, there's 7 of them, but the drive unit would need sealing on the engine side to keep the pinions in oil, even if the oil-fed drive unit bearings were replaced with sealed bearings,(although the stock left hand bearing is a thrust bearing) but there's still gonna be big torque/centrifugal forces coming from the pinion/bevel area, the spacer setup would need to be very solid, not 100% sure, but I think one of the trike guys on this site did extend the spline shaft by welding.

Comment

-

Chop,

You may be able to have a new shaft built? If you could, build the spacer from a block of aluminum, and the new shaft the same length over. If it works, You may be able to find a home for 10 or 15 of the mods, and keep the "per piece" price down.

Just a thought....(hope no one smells the smoke )

)

RayRay Matteis

KE6NHG

XS1100 E '78 (winter project)

XS1100 SF Bob Jones worked on it!Comment

-

XSchop, do you mean to say you want to weld the splined shaft?

If I wanted to do this I would machine the ends of the two shafts and have them Electron Beam welded. I know a guy that has a very sophisitacated welding business. EB, friction, laser, etc.

with EB welding it's very precise. That would be my first

suggestion.

Cheers, 50garyComment

-

extended shaft

You guys are all thinking correctly on this one.The best way is to extend the shaft so you don't have to split cases to remove Middle Driven Gear. I have called a few shops here and they are all in the "oil field business" and don't act very confident they could do this. I am determined to do this mod. I would be glad to collaborate. I personally want to extend the shaft by 35mm, this would allow an extra 70mm width to the existing 130mm rear tire (200mm). Also planned to make the M/D spacer from a block of aluminum like DennyZ says. One thing for 50Gary, Could it be posssible to cut only 1 donor shaft and extend it so you don't have to buthcher 2 of them? PM me and lets get this ball rolling. I have a completely removed shaft at this time and can mail out....Thanks you guys.....chopMDRNF

79F.....Not Stock

80G......Not Stock Either....In the worksComment

-

spacer

I looked into this homemade spacer which is 9mm thick according to the UK guys. I see why, because you could move the stock M/D out this far and still have some decent grab at the middle driven gear without messing with the shaft.

However I want mine CNC machined With the Guide Surface (like the M/D gear housing has)precision machined on Both sides of the spacer.MDRNF

79F.....Not Stock

80G......Not Stock Either....In the worksComment

-

For sure, this is a "go big" or "stay home" project. Makes no sense not to expect a 200mm on the rear. A 35mm extension is what I am thinking also.

The spacer would be milled from a 2" block of aluminum. I have not research the availablility of 35mm longer bolts. Worse case we could use thread stock and nutsDZ

Vyger, 'F'

"The Special", 'SF'

'08 FJR1300Comment

Comment