Thinking out loud

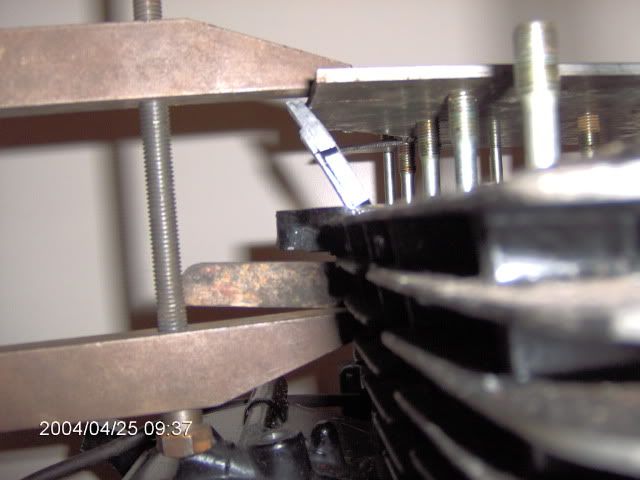

Depending on what parts you are trying to save/use,

I am wondering if there is some way you could use the pistons as an assist in removing the cylinders,

I am not suggesting you do this however put something on top of the pistons

and also something across the deck of the cylinder and rotate the crank and use the pistons as a push tool along with prying at the base of the cylinders .

I am aware that it may damage the rods or crank(or maybe not) but maybe this will inspire a better or modified version of this idea from some one else here.

Again I was just thinking out loud

Good luck

Depending on what parts you are trying to save/use,

I am wondering if there is some way you could use the pistons as an assist in removing the cylinders,

I am not suggesting you do this however put something on top of the pistons

and also something across the deck of the cylinder and rotate the crank and use the pistons as a push tool along with prying at the base of the cylinders .

I am aware that it may damage the rods or crank(or maybe not) but maybe this will inspire a better or modified version of this idea from some one else here.

Again I was just thinking out loud

Good luck

)

)

Comment