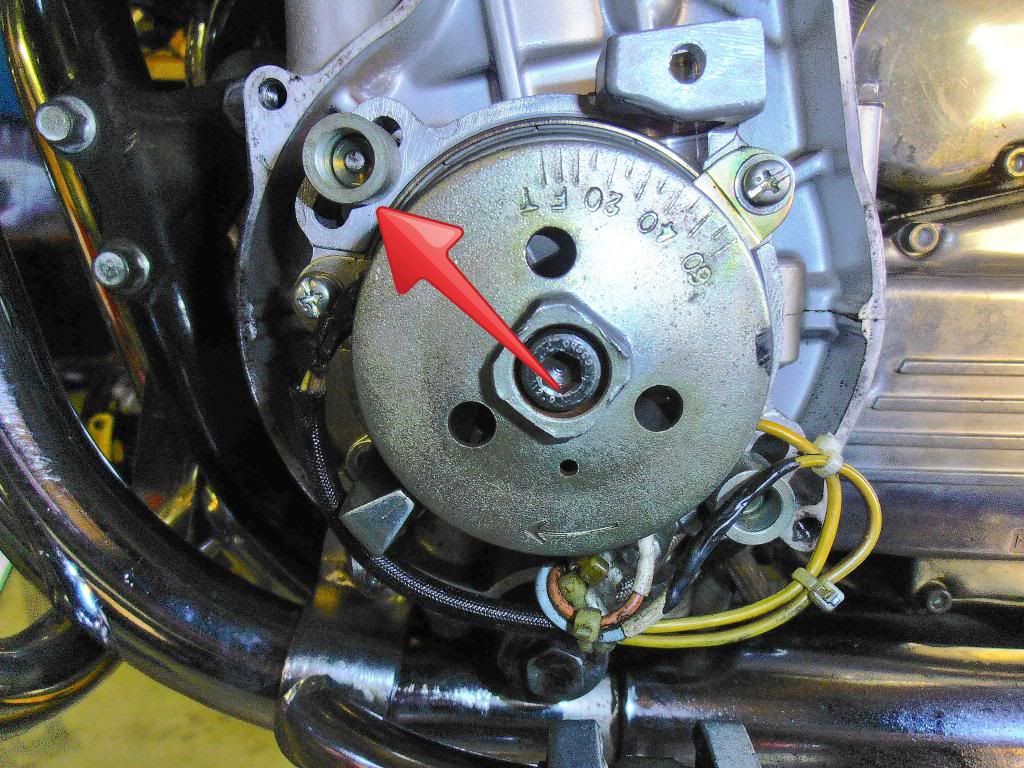

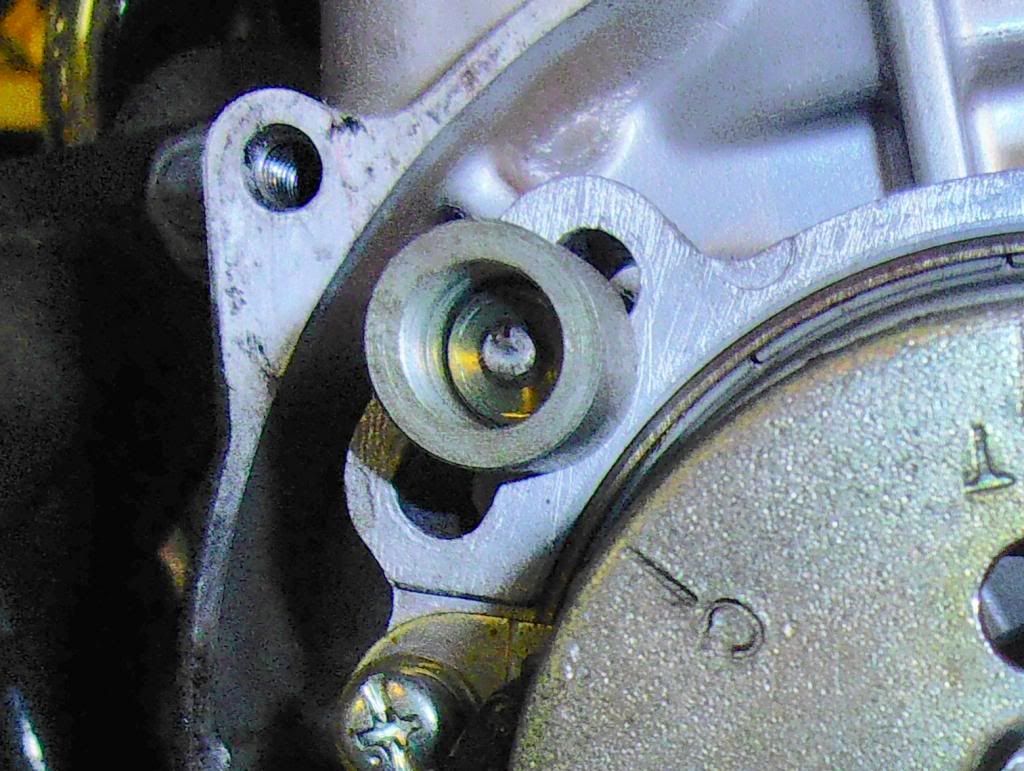

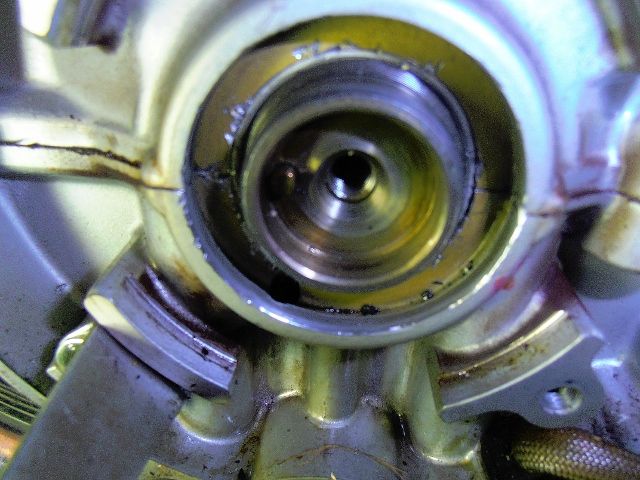

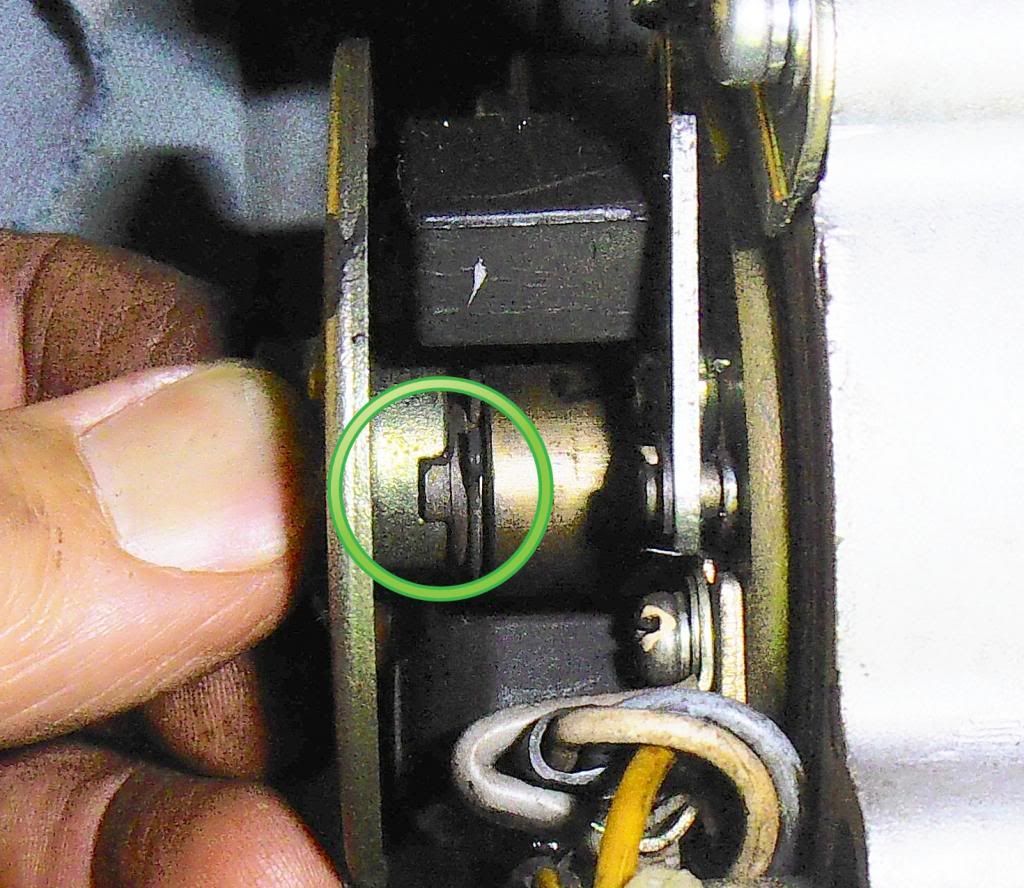

Well, I'm ready to change out the left side crankshaft seal. Searched here for Portero's write-up from 2005 but I can't find it. I believe I need to pull the timing plate, the pickups, and anything else that's in the way. Then somehow poke a hole thru the wall of the old seal and pry it out with a screwdriver. Lube the inner ring of the seal with oil and the outside of the seal with yamalube then drive it in carefully and straight til it's just about flush. Give it time for the sealant to set up before running the engine.

What I have no idea about is the re-installation of the timing plate and all. Should I need to re-time the engine?

Any steps or techniques I should be mindful of?

scoot

What I have no idea about is the re-installation of the timing plate and all. Should I need to re-time the engine?

Any steps or techniques I should be mindful of?

scoot

/

/

Comment