those bolts look good

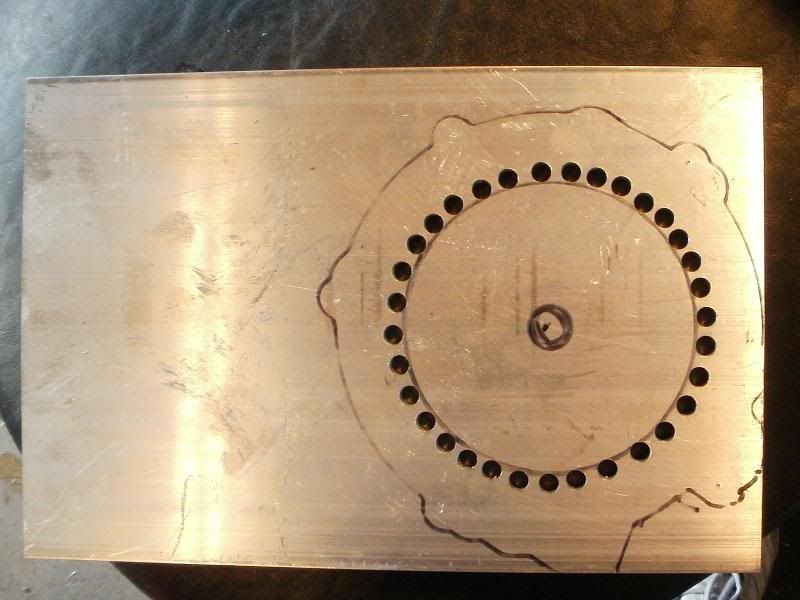

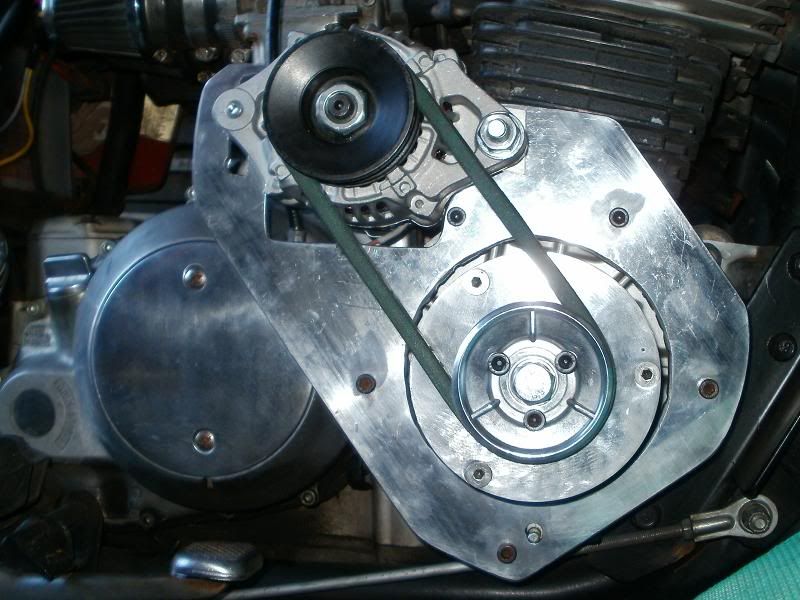

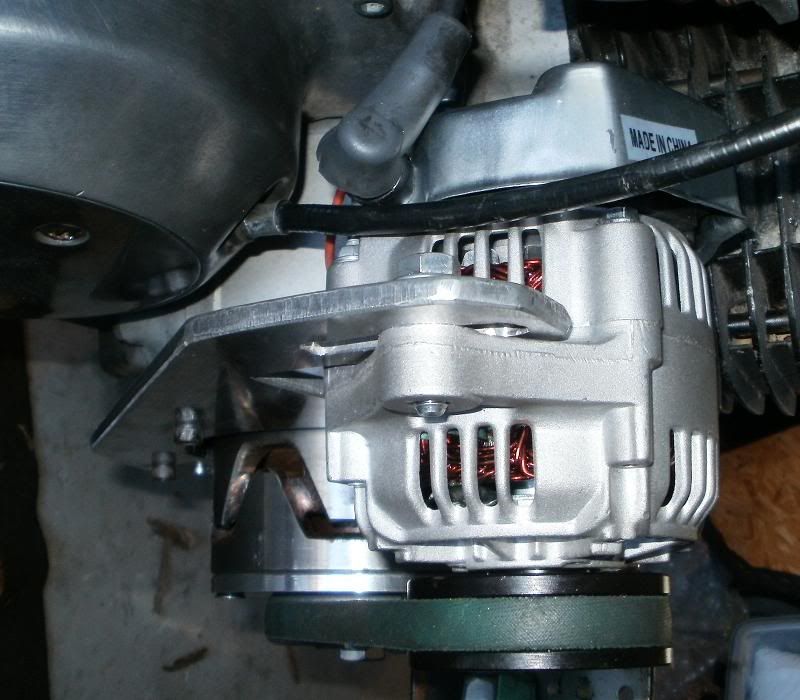

considering you've already tapped the holes

for the previous bolts they'l be sweet.

i wouldnt worry about locktite on the rotor to

the crank the tapered designed of both would

hold it in place and the rotor can be a bugger to

get off at the best of times.

considering you've already tapped the holes

for the previous bolts they'l be sweet.

i wouldnt worry about locktite on the rotor to

the crank the tapered designed of both would

hold it in place and the rotor can be a bugger to

get off at the best of times.

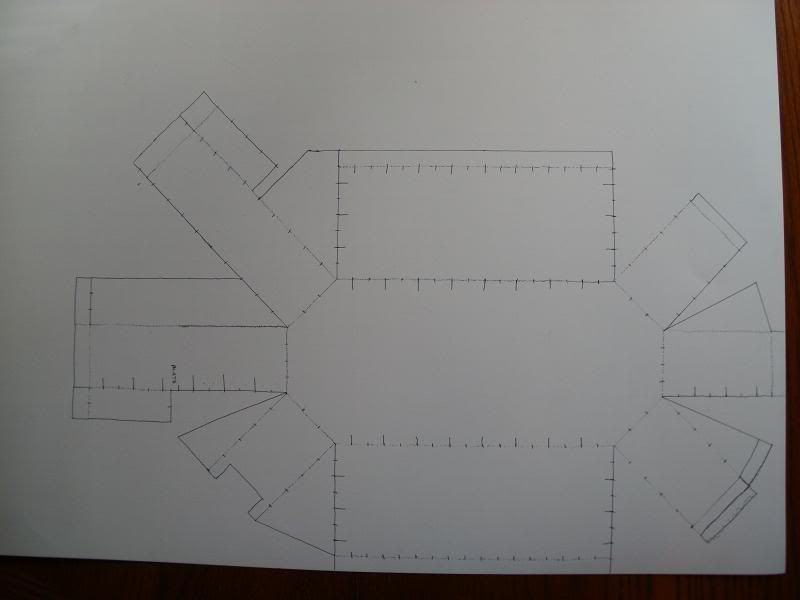

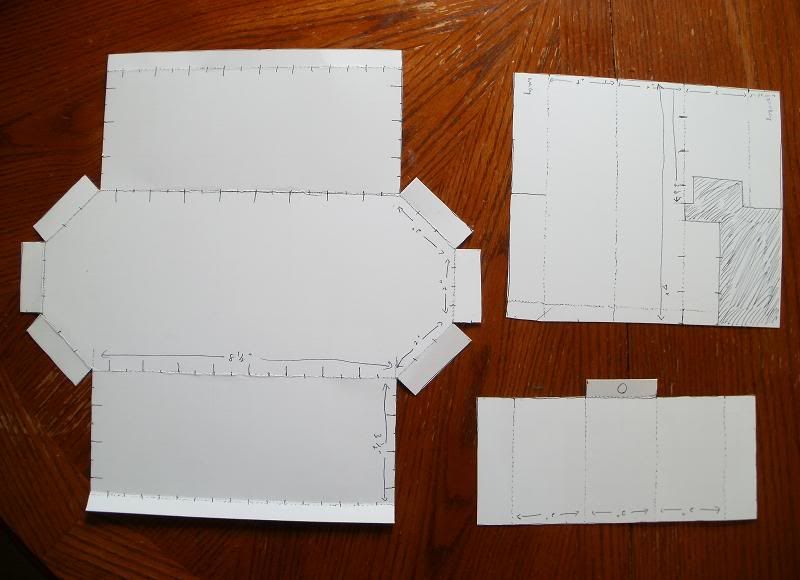

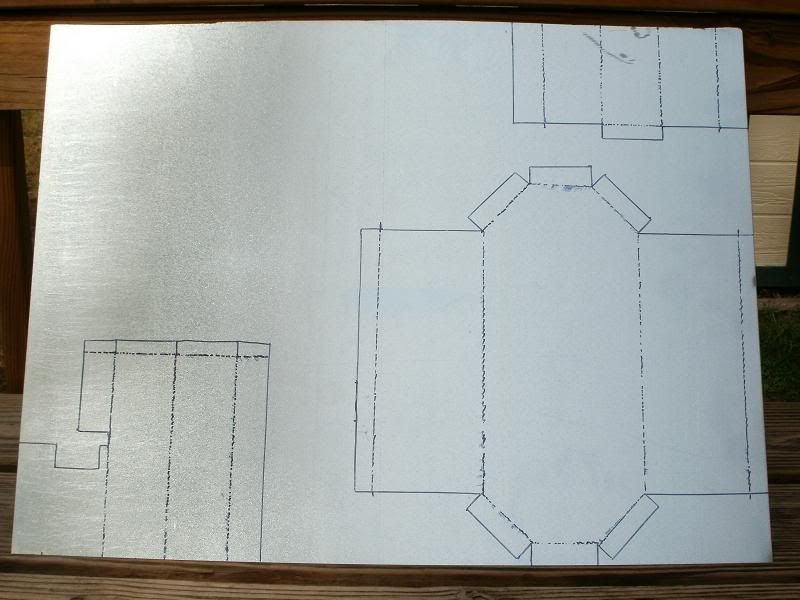

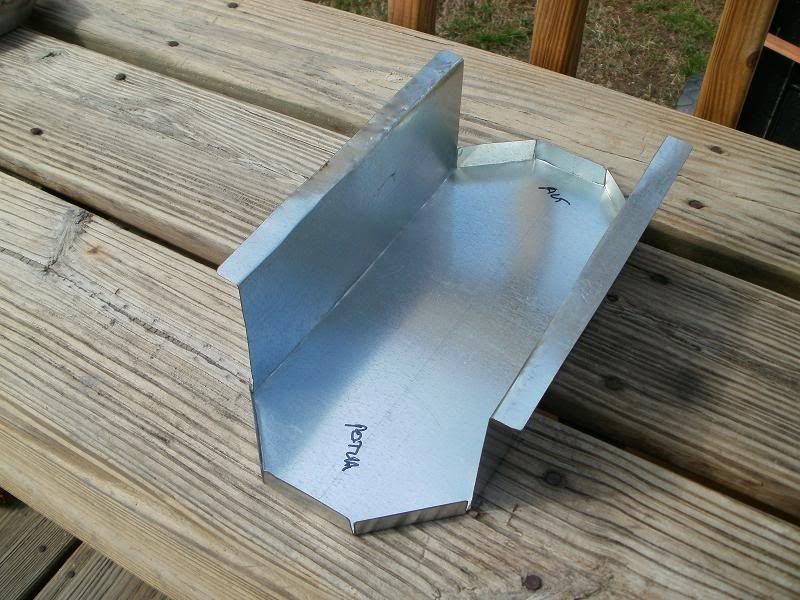

Again, thanks to Crazy Steve for helping me to see a simpler way of doing it, involved 3 pieces, but much simpler than trying to make it out of 1 piece with so many bends/cuts!!

Again, thanks to Crazy Steve for helping me to see a simpler way of doing it, involved 3 pieces, but much simpler than trying to make it out of 1 piece with so many bends/cuts!!

Comment