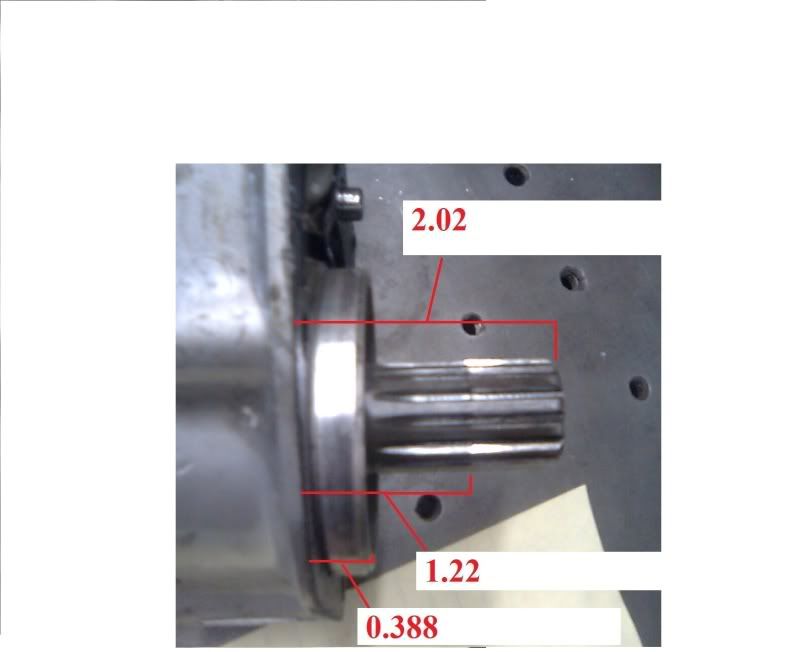

I now have done enough Middle drives to where I feel comfortable in the dimensions needed for an adapter that will go between the factory middle drive housing and inner middle drive gear for a 100% bolt-on solution to the FJR-1300 swingarm that MathH pioneered and now Mr. freeze is working on.... 30mm spacer is where it is at.... but luckily, the insertion depth on all the middle drives that I have removed are all within 0.75 mm of each other....

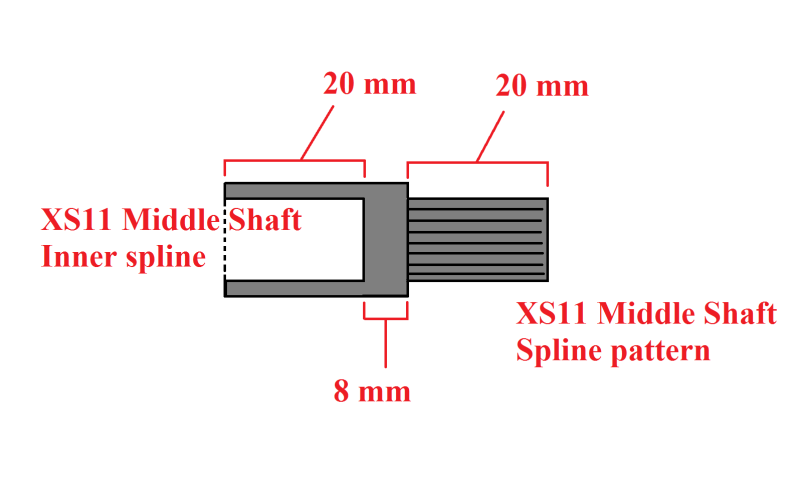

I need to know the shaft spline pattern to finalize the adapter drawing....hopefully we have a gear cutter on board....

As you can see, the middle drive shaft insertion depths on all these shafts are exactly the same with plenty of play for various spacers of which I have already machined one at 30mm with oiling ports included for the middle drive gear oil....

I need to know the shaft spline pattern to finalize the adapter drawing....hopefully we have a gear cutter on board....

As you can see, the middle drive shaft insertion depths on all these shafts are exactly the same with plenty of play for various spacers of which I have already machined one at 30mm with oiling ports included for the middle drive gear oil....

Let me know if you have any questions, like I said I'm no expert and I only have a bit of experience but I am very mechanically inclined.

Let me know if you have any questions, like I said I'm no expert and I only have a bit of experience but I am very mechanically inclined.

Comment