Cams

Collapse

X

-

Pic? Sounds like a great tool, but I am having trouble visualizing it.

I originally ground the foot of the C clamp in a moon shape as seen here, but have since taken that foot completely off and ground the nub under the foot to a point. I then drilled a dimple into the shim bucket face. The point of the clamp goes in this dimple so it doesn't walk around while I tighten the clamp. This way, there's no chance of scratching the surface the bucket slides up and down in.

Like I said.. probably not the best option for all, but this does make it easy to get the keepers on and off.

Next, I'll have to show you the "Southern engenuity" tool I rigged up to get those stuck cylinders up off the base of the motor..

TodTry your hardest to be the kind of person your dog thinks you are.

You can live to be 100, as long as you give up everything that would make you want to live to be 100!

Current bikes:

'06 Suzuki DR650

*'82 XJ1100 with the 1179 kit. "Mad Maxim"

'82 XJ1100 Completely stock fixer-upper

'82 XJ1100 Bagger fixer-upper

'82 XJ1100 Motor/frame and lots of boxes of parts

'82 XJ1100 Parts bike

'81 XS1100 Special

'81 YZ250

'80 XS850 Special

'80 XR100

*Crashed/Totalled, still ownComment

-

Cama, Valves And Stuff

To remove the valve springs with the head off I use a "C" valve spring compressor/removal tool I bought fron Snap On Tools.

You should not use the late head with the early pistons because the late head has a larger combustion chamber due to the larger valves, about 3 cc's and consequently this will cause a large loss of compression due to the smaller domes of the early pistons. The early pistons also have smaller valve reliefs designed for the smaller valves of the early head.

The domes on the late pistons for the standard bore measure 6 cc's and the domes on the Wiseco pistons for the 74 mm bore measure 6.6 cc's. The domes on the Wiseco's are shorter because the bore is bigger and the dome voluumns are essentially the same. A cheap upgrade for a 78-79 combo would be to use the late piston with the early head which would increase the compression ratio by about three quarters of a point or about 3% more power.

The late head in stock form will flow about 10% more than a 78-79 head in stock form which equates to about 5% more power.

The early cams will make about 3 HP & 2 ft. lbs. of torque more than the late cams from 4,000 rpm up, about the same at 3,000 rpm and less from idle to 3,000 rpm. I've checked this on the dyno and a fellow member named Gene from Florida found similiar results. I've posted the timing specs and event angles on these cams previously and so I won't list them again. Installing the cams on the stock marks will work/run but you should degree the cams no matter which you are using. I used a "Bridgeport" to slot my cam sprokets but you can buy them new from Mega-Cycle already slotted.

If you have a bagger with the 750-850 FD you don't want the early cams but should use the late ones with the intake advanced 5 degrees because it's low end torque that is most important to you because of the high gear ratio. You can fiddle with the intake valve closing and static compression but it's 150-160 pounds of pumping compression that you are after in a torquer motor. All things equal, the quicker the intake valve closes the more pumping compression you will have. Attached is a picture of the tools employed to degree the cams on a "certain" Honda 1100-F. 81 Black "1179" Xcessively trick Super Special. One owner (me).

81 Black "1179" Xcessively trick Super Special. One owner (me).Comment

-

Timing, Compression and Displacement

Mention is made that altering the intake valve closing event, changing the cam timing overlap and increasing the displacement with a big bore kit will effect the intake signal which will effect the rate the slides lift and the jetting. This is particualary true when dealing with overlap and more cubic inches.To remove the valve springs with the head off I use a "C" valve spring compressor/removal tool I bought fron Snap On Tools.

You should not use the late head with the early pistons because the late head has a larger combustion chamber due to the larger valves, about 3 cc's and consequently this will cause a large loss of compression due to the smaller domes of the early pistons. The early pistons also have smaller valve reliefs designed for the smaller valves of the early head.

The domes on the late pistons for the standard bore measure 6 cc's and the domes on the Wiseco pistons for the 74 mm bore measure 6.6 cc's. The domes on the Wiseco's are shorter because the bore is bigger and the dome voluumns are essentially the same. A cheap upgrade for a 78-79 combo would be to use the late piston with the early head which would increase the compression ratio by about three quarters of a point or about 3% more power.

The late head in stock form will flow about 10% more than a 78-79 head in stock form which equates to about 5% more power.

The early cams will make about 3 HP & 2 ft. lbs. of torque more than the late cams from 4,000 rpm up, about the same at 3,000 rpm and less from idle to 3,000 rpm. I've checked this on the dyno and a fellow member named Gene from Florida found similiar results. I've posted the timing specs and event angles on these cams previously and so I won't list them again. Installing the cams on the stock marks will work/run but you should degree the cams no matter which you are using. I used a "Bridgeport" to slot my cam sprokets but you can buy them new from Mega-Cycle already slotted.

If you have a bagger with the 750-850 FD you don't want the early cams but should use the late ones with the intake advanced 5 degrees because it's low end torque that is most important to you because of the high gear ratio. You can fiddle with the intake valve closing and static compression but it's 150-160 pounds of pumping compression that you are after in a torquer motor. All things equal, the quicker the intake valve closes the more pumping compression you will have. Attached is a picture of the tools employed to degree the cams on a "certain" Honda 1100-F. 81 Black "1179" Xcessively trick Super Special. One owner (me).

81 Black "1179" Xcessively trick Super Special. One owner (me).Comment

-

Early cams vs Late cams........Dyno Results

It took some digging through my dyno files but I finally found one of the test done on the comparison between the early cams vs the late.I ran 78 cams on a late head with the bigger valves for quite a while. It ran alright, but with the timing the way it was, we could get almost no vacuum to do a carb synch.. like maybe 1-2hg. It would run good at high RPM, but I didn't realize what I was missing on the bottom until I put the right cams back in it a little over a year ago. I'd say at LEAST double the low end grunt versus the 78 cams. There's plenty of piston to valve clearance.. it just isn't the hot mod that people think.

And before you say anything, the valves were good and shimmed correctly and the cam lobes were all still in spec. So.. short answer to my rambling... use the cams that were designed for the head.

What I will say though for your plan, is the later heads had a higher valve relief area versus the early heads..(Space above the piston in the head while at top dead center) and by going to the later head on your early motor, you're going to lose some compression. The early 78-79 model pistons were actually LOWER domed than the later 80-82 pistons. They domed the pistons higher in the 80-82 models to try to make up for some of the compression lost in the larger valve relief area.. but didn't get it all made up. By putting this late head on the early motor, you will drop your compression numbers even further still than the stock later motors.

Clean your 78 head up, put in some new valve guides, lap your valves, shim them.. and it'll be like a new motor if it's only got 40k miles. The 78 was the fastest of these bikes... stick with the winning combination.

Now.. someone with a LATER model engine with the higher domed pistons (Later stock pistons are even higher domed than the Wiseco replacement pistons) that can find a 78 head and cams to put on...

Tod

The chart shows that the early ones are stronger both in HP and torque above 2,000 rpm but at anything below 2,000 rpm the late ones are stouter.

The early ones have over twice the overlap that the late ones do which will have an effect on the intake signal to the carbs, jetting and so forth.

In 1980 Yamaha used the late cams with the weird centerlines (105 degrees on the intake and 113 on the exhaust) to meet the more stringent exhaust emissions standards of the era in addition to the fact they came out with the Venturer model with the factory fairing and bags.

They used the larger valved head to make up for the difference in the hp loss of the cams. Way back in 1981, Cycle Magazine did a cam flog on an 81 Special where they replaced the cams with the early ones which was all the rage during that time.

The bottom line is you can't get something for nothing and more cam duration will make more hp however it won't make more everywhere unless the original cam is way too small for the application and so it's up to the end user to tune his combo for his application.

81 Black "1179" Xcessively trick Super Special. One owner (me).

81 Black "1179" Xcessively trick Super Special. One owner (me).Comment

-

I personally didn't notice a whole lot of difference in the top end power between the two. Some.. but I'm only judging by a "Seat of the pants" dyno. What I did notice was a LOT more grunt on the bottom end. So much more so that I felt it rediculous to ever swap back.

TodTry your hardest to be the kind of person your dog thinks you are.

You can live to be 100, as long as you give up everything that would make you want to live to be 100!

Current bikes:

'06 Suzuki DR650

*'82 XJ1100 with the 1179 kit. "Mad Maxim"

'82 XJ1100 Completely stock fixer-upper

'82 XJ1100 Bagger fixer-upper

'82 XJ1100 Motor/frame and lots of boxes of parts

'82 XJ1100 Parts bike

'81 XS1100 Special

'81 YZ250

'80 XS850 Special

'80 XR100

*Crashed/Totalled, still ownComment

-

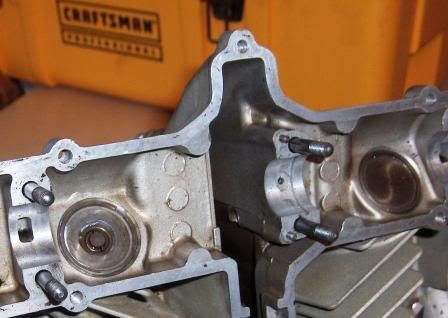

The block, pistons and bottom end is finished but I haven't completed the head yet.

The combustion chambers have to be opened up to match the larger bore which requires a lot of precise grinding. I welded up the original quench/squish areas of the head which required removing the seats and guides because of the heat. Once welded, you have to go in with a tootsie roll and regrind/roll the quench pads but the quench/squish area won't be as large as stock. Essentially you have to convert the stock combustion chamber which is 72.5 mm OD to a finished diameter of 78 mm while maintaining a piston to deck clearence of .050 including the gasket.

The block and piston deal was a no brainer once I got the pistons but the head has turned into a lot of work. Actually it wasn't that simple because the case had to be clearenced for the larger OD sleeves which required a custom base gasket made from a .020 thick sheet of gasket material. I started this project with 3 motors but I still had to buy some new transmission parts to get one good one and use the new clutch basket I've been hoarding.

It is a lot of work but I do a little toward it when I have the time and once summer is over and the drag racing season ends I will knock it out.

In hindsight, I should have sent the head to Ward and had them do their deal on the porting and chamber modifications but I got ahead of myself and got the pistons first...big mistake considering the fact I will have to send it to them anyway for the porting and re-installation of the guides and seats.

Anyway, that's were I'm at and thanks for your interest.

Dan81 Black "1179" Xcessively trick Super Special. One owner (me).Comment

Comment