Vacuum advance should be connected up when setting the ignition timing. It should be unconnected and #2 carb nipple plugged when checking the centrigugal advance timing.

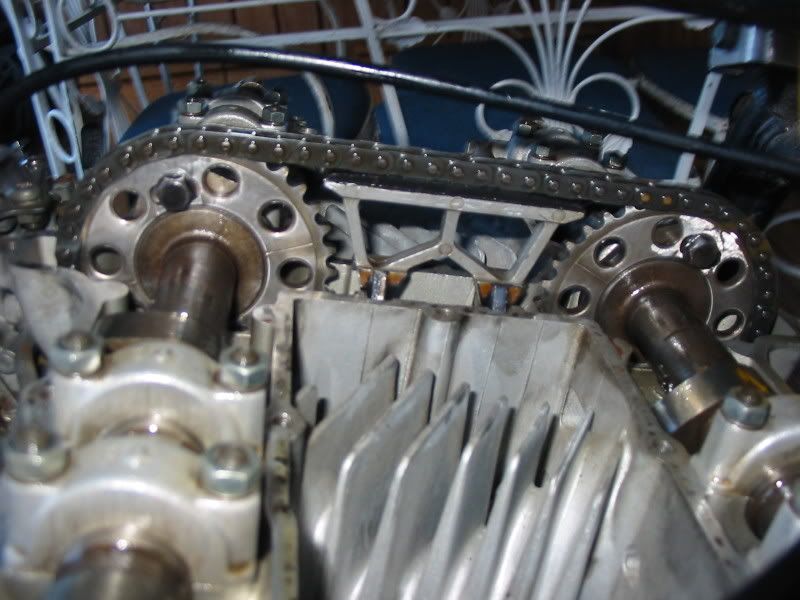

Your cams do not look way out to me. The small dots on the cams will not necessarily line up perfectly with the cam cap arrows. If you are off by one cam tooth then your CAM will be out 11.25 degrees (23 degrees at the crank) which will be quite noticeable (and probably quite expensive).

If you are at true TDC in the picture (and I suspect you are not)then either your timing wheel is way off or your pointer is way bent or both. The stock timing wheel is not very accurate even when factory new. If you back off the center bolt and then just snug it back up then I bet you can move your wheel +/-5 degrees back and forth.

You need to confirm true TDC and the best way to do this is using a piston stop and a degree wheel. I gathered these items a long time ago when I installed slotted cam sprockets so I could tinker with cam timing. After seeing how much slop there is in the timing wheel I do not even rely on it anymore. It only takes ten minutes to pull the plugs, set up the degree wheel and find TDC so I even use it when I check my ignition timing.

If you are this unsure where your TDC is then I really suggest you invest in a degree wheel and piston stop. MotionPro makes a nice one and you can make your own piston stop and probably obtain both for under $30.00.

Your cams do not look way out to me. The small dots on the cams will not necessarily line up perfectly with the cam cap arrows. If you are off by one cam tooth then your CAM will be out 11.25 degrees (23 degrees at the crank) which will be quite noticeable (and probably quite expensive).

If you are at true TDC in the picture (and I suspect you are not)then either your timing wheel is way off or your pointer is way bent or both. The stock timing wheel is not very accurate even when factory new. If you back off the center bolt and then just snug it back up then I bet you can move your wheel +/-5 degrees back and forth.

You need to confirm true TDC and the best way to do this is using a piston stop and a degree wheel. I gathered these items a long time ago when I installed slotted cam sprockets so I could tinker with cam timing. After seeing how much slop there is in the timing wheel I do not even rely on it anymore. It only takes ten minutes to pull the plugs, set up the degree wheel and find TDC so I even use it when I check my ignition timing.

If you are this unsure where your TDC is then I really suggest you invest in a degree wheel and piston stop. MotionPro makes a nice one and you can make your own piston stop and probably obtain both for under $30.00.

I had seen postings of yours relating to changing cam timing so I believe you're pretty tuned in to crank/cam timing issues. If both cams were advanced or retarded by a tooth, would the motor still run or are saying it would self destruct? My motor runs pretty good but peters out around 5500 rpm ... see my initial post. AND ... when you degreed the crank with the wheel, you had to turn the engine backwards and to find TDC, right? Is that OK? I could use a cruder method since we're dealin' with 11.5 cam degrees per tooth. That's about what it looks like I'm off .....

I had seen postings of yours relating to changing cam timing so I believe you're pretty tuned in to crank/cam timing issues. If both cams were advanced or retarded by a tooth, would the motor still run or are saying it would self destruct? My motor runs pretty good but peters out around 5500 rpm ... see my initial post. AND ... when you degreed the crank with the wheel, you had to turn the engine backwards and to find TDC, right? Is that OK? I could use a cruder method since we're dealin' with 11.5 cam degrees per tooth. That's about what it looks like I'm off .....

I guess I'm glad ... didn't really feel like tearin' things apart anyway.

I guess I'm glad ... didn't really feel like tearin' things apart anyway.

Comment