I am rebuilding and trying a set of FJ carbs. I have learned some very valuable lessons from these carbs.

The fist is be careful when using the automatic center punch. It can mash and flare the ends of the pin. This resulted in a broken post as well as having to cut the pins with a dremel cutting disk between the posts and the floats in order to get everything removed. The flared ends of the pins became completely frozen in the float bracket. Worst time I have EVER had removing floats.

The second is that soldering float posts is a no go. At least, it was for me. Someone else maybe could/has done it, but I could not get the solder to flow.

The third is that there just really is no GOOD way to fix a broken post.

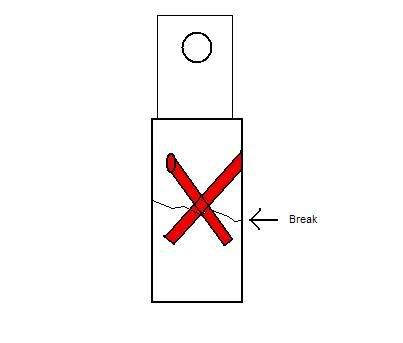

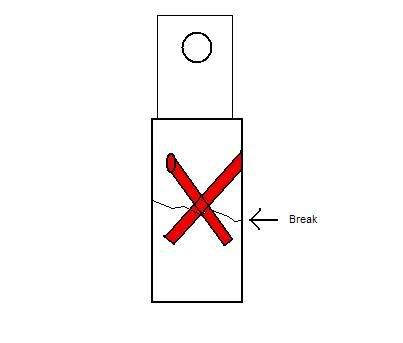

I did come up with something though and thought I would share. To fix the post I drilled 2 very small passages through both pieces (red in the pic). If you were looking straight down on the post one would be and 6 o'clock and the other at 3.

Then I took the super tiny bit that I drilled the holes with and broke it in half to use as reinforcing pins. Then I filled all the holes and mating surfaces with good old jb weld inserted the pins, clamped it and left it to set. Today I cut the exposed pin ends off and coated the JBW with clear fingernail polish (don't ask me, Prom said it was the way to go in one of the old threads I read through to research repairs

) The X arrangement of the pins seems to add a lot a structural integrity. I just hope things can hold up to the gas.

) The X arrangement of the pins seems to add a lot a structural integrity. I just hope things can hold up to the gas.

The fist is be careful when using the automatic center punch. It can mash and flare the ends of the pin. This resulted in a broken post as well as having to cut the pins with a dremel cutting disk between the posts and the floats in order to get everything removed. The flared ends of the pins became completely frozen in the float bracket. Worst time I have EVER had removing floats.

The second is that soldering float posts is a no go. At least, it was for me. Someone else maybe could/has done it, but I could not get the solder to flow.

The third is that there just really is no GOOD way to fix a broken post.

I did come up with something though and thought I would share. To fix the post I drilled 2 very small passages through both pieces (red in the pic). If you were looking straight down on the post one would be and 6 o'clock and the other at 3.

Then I took the super tiny bit that I drilled the holes with and broke it in half to use as reinforcing pins. Then I filled all the holes and mating surfaces with good old jb weld inserted the pins, clamped it and left it to set. Today I cut the exposed pin ends off and coated the JBW with clear fingernail polish (don't ask me, Prom said it was the way to go in one of the old threads I read through to research repairs

) The X arrangement of the pins seems to add a lot a structural integrity. I just hope things can hold up to the gas.

) The X arrangement of the pins seems to add a lot a structural integrity. I just hope things can hold up to the gas.

Comment