Hey Folks,

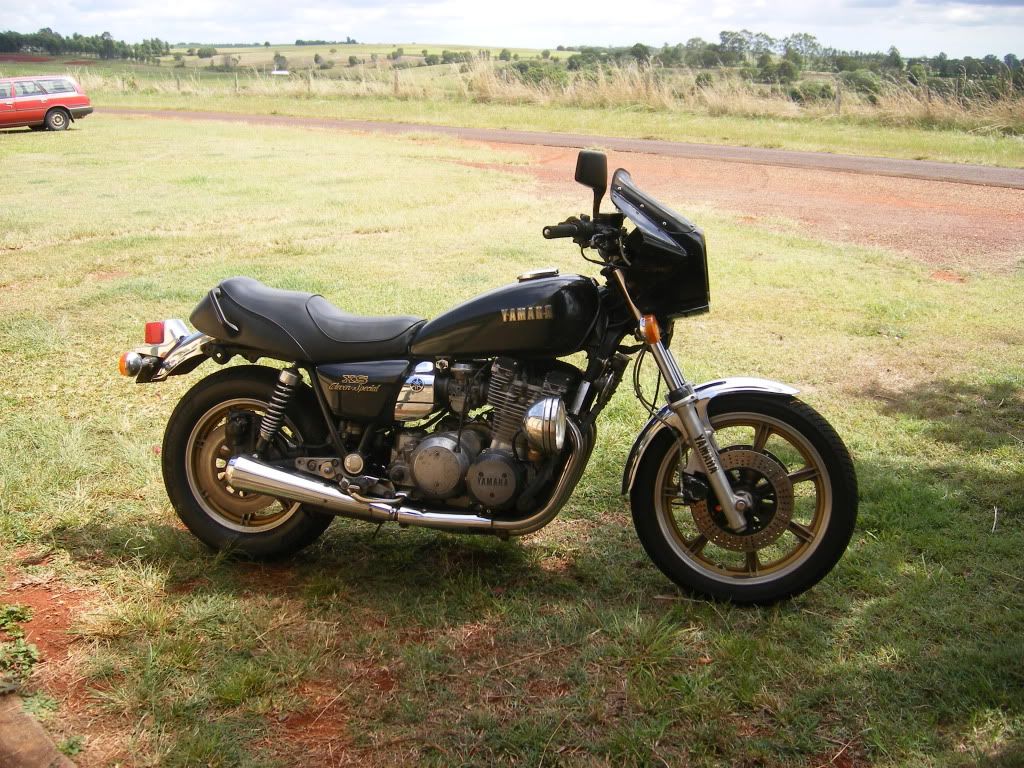

Okay, now that my front brake Special mod is done and functioning, I'm turning my attention to the next project that may hopefully provide more benefit to members in need of replacing worn/rusted out headers at a reasonable cost.

First the design. I don't have any fancy mandrel bending capability! I've already acquired a modest amount of pipe sections....straight and mandrel bent. I have 90 degree bends that can be cut at 45 as well. I've researched the places to acquire the pipe sections, and they want astronomical prices for the "Y" sections....like $45.00 or more EACH!

I've already acquired a modest amount of pipe sections....straight and mandrel bent. I have 90 degree bends that can be cut at 45 as well. I've researched the places to acquire the pipe sections, and they want astronomical prices for the "Y" sections....like $45.00 or more EACH!  So... the first problem is the junction of the 2-1 pipes for each side. Most folks use or want a 4-2 system, so that's what I'm going to try first!

So... the first problem is the junction of the 2-1 pipes for each side. Most folks use or want a 4-2 system, so that's what I'm going to try first!

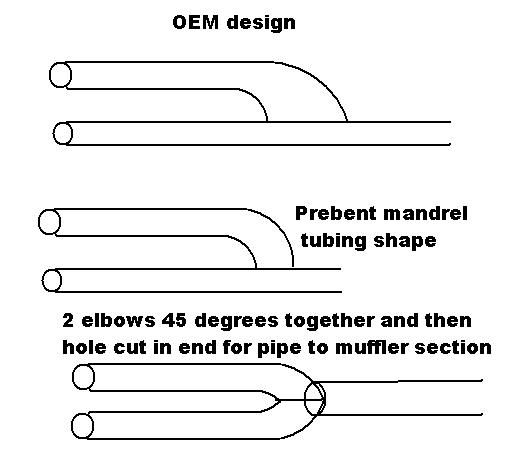

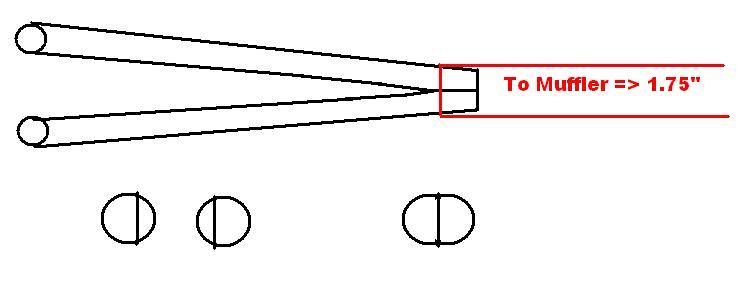

The OEM design of the headers have the inner section being both flattened so that it's a wider area and at a 45 degree type curve as it joins with the straight section of the outer pipe. My prebent sections are just ROUND, I don't know how well I could FLATTEN that section prior to attaching/welding it to the other pipe into its SIDE, as well as cutting out the matching OVAL shape, and also have enough room to be able to get the TIG tip inbetween the 2 sections!?

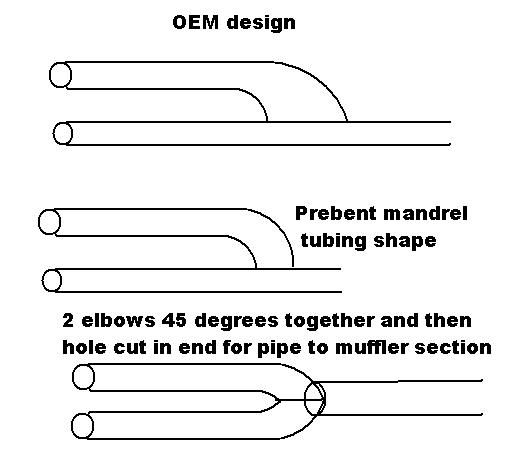

See the simple diagram below. First shows the OEM shape. Second shows just joining the pipe using a 90 degree bend.....as variation of this could be done with any angle...the header pipes don't have to be parallel....they could be angled at a slight converging angle to the junction joint, so that the bend can be cut at any angle between 90 and 45. The 3 is cutting and using 2 bends, each 45 degrees of curve, cutting a parallel cut so that both ends could be welded up, and then a hole cut in the joined end to afix the round pipe section that goes to the muffler. This last idea would provide the same bend and theorhetically the same resistance vs. 1 straight thru and 1 having to go around a 90/45 degree bend!?

Okay, thoughts, ideas, etc.?!

T.C.

Okay, now that my front brake Special mod is done and functioning, I'm turning my attention to the next project that may hopefully provide more benefit to members in need of replacing worn/rusted out headers at a reasonable cost.

First the design. I don't have any fancy mandrel bending capability!

I've already acquired a modest amount of pipe sections....straight and mandrel bent. I have 90 degree bends that can be cut at 45 as well. I've researched the places to acquire the pipe sections, and they want astronomical prices for the "Y" sections....like $45.00 or more EACH!

I've already acquired a modest amount of pipe sections....straight and mandrel bent. I have 90 degree bends that can be cut at 45 as well. I've researched the places to acquire the pipe sections, and they want astronomical prices for the "Y" sections....like $45.00 or more EACH!  So... the first problem is the junction of the 2-1 pipes for each side. Most folks use or want a 4-2 system, so that's what I'm going to try first!

So... the first problem is the junction of the 2-1 pipes for each side. Most folks use or want a 4-2 system, so that's what I'm going to try first! The OEM design of the headers have the inner section being both flattened so that it's a wider area and at a 45 degree type curve as it joins with the straight section of the outer pipe. My prebent sections are just ROUND, I don't know how well I could FLATTEN that section prior to attaching/welding it to the other pipe into its SIDE, as well as cutting out the matching OVAL shape, and also have enough room to be able to get the TIG tip inbetween the 2 sections!?

See the simple diagram below. First shows the OEM shape. Second shows just joining the pipe using a 90 degree bend.....as variation of this could be done with any angle...the header pipes don't have to be parallel....they could be angled at a slight converging angle to the junction joint, so that the bend can be cut at any angle between 90 and 45. The 3 is cutting and using 2 bends, each 45 degrees of curve, cutting a parallel cut so that both ends could be welded up, and then a hole cut in the joined end to afix the round pipe section that goes to the muffler. This last idea would provide the same bend and theorhetically the same resistance vs. 1 straight thru and 1 having to go around a 90/45 degree bend!?

Okay, thoughts, ideas, etc.?!

T.C.

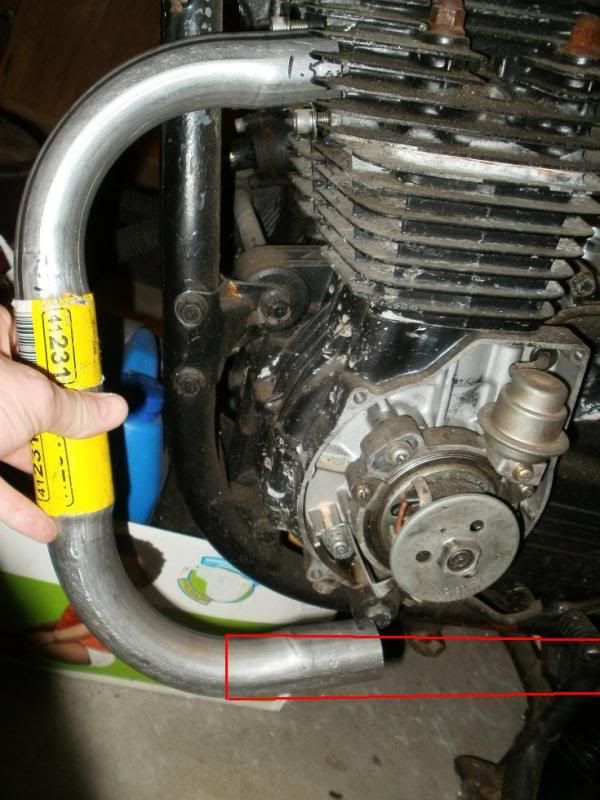

How about the inside of the crossover? Got pics of that too?

How about the inside of the crossover? Got pics of that too?

Comment