Checking the drive unit spline it seems worn a lot. Hopefully what it is is the L/H bearing which I remember stuffing up by hitting the race with a hammer the wrong way back to front. The bearing was rattly but skimping on another $25 might cost a whole spline. I removed the drive unit and checked everything inside.

DEFINITELY MORE WEAR on the spline teeth. Will put in a new bearing properly this time, then see what happens. Sprockets are still brand new condition but have destroyed an el-cheapo chain already. This thing is hauling ass at the ton in 4th - hit the gas at 5500 revs and it's hitting 200KPH in a blink.

DEFINITELY MORE WEAR on the spline teeth. Will put in a new bearing properly this time, then see what happens. Sprockets are still brand new condition but have destroyed an el-cheapo chain already. This thing is hauling ass at the ton in 4th - hit the gas at 5500 revs and it's hitting 200KPH in a blink.

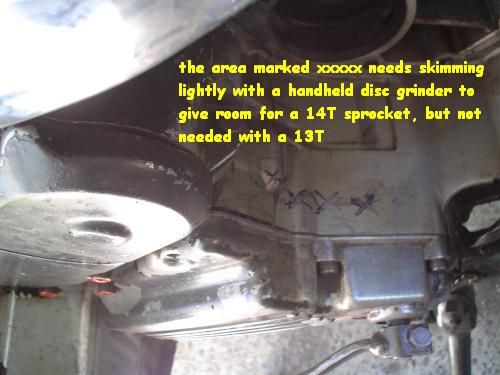

to fit a 14 tooth sprocket.

to fit a 14 tooth sprocket.

No discernable flex though. Will splash out on high tensile bolts all round, and some extra bracing.

No discernable flex though. Will splash out on high tensile bolts all round, and some extra bracing.

But putting in H.T. bolts is a start. It's quite possibly nothing to do with flexing - tap the unit with a hammer, it feels stiff and solid. Did I mention a bearing was a bit loose at the start? I still prefer a road cruiser on the XS. 2 hour job to throw all the shaft parts back on. Still have a brand new Conti Tour 130/90/17 on the XS back end. Seems a waste

But putting in H.T. bolts is a start. It's quite possibly nothing to do with flexing - tap the unit with a hammer, it feels stiff and solid. Did I mention a bearing was a bit loose at the start? I still prefer a road cruiser on the XS. 2 hour job to throw all the shaft parts back on. Still have a brand new Conti Tour 130/90/17 on the XS back end. Seems a waste

Comment