Hey TC! Burn away! I've got a couple of spare swing arms in case things should go awry. It will be worth it just to find out if the bracing will work.

Stiffening up Swingarm?

Collapse

X

-

The right side of the swing arm is thick enough to weld on. The drive tube side is very thin.

It seems to me that the best way to stiffen the swing arm is to run "U" shaped square or round tube piece from one side, up and over the tire to the other side. Then run an arc'ed tube from the center of the "U" shaped piece to the swing arm center tube (the one with the swing arm pivots in it. Seems simple enough until ya get right down to it. The brake caliper mount gets in the way on the right side and there is no real good place to attach to the drive tube side. The "U" shaped piece would have to fit snug to the tire so it would not hit on hard bumps. It turns out it is just not that easy. I guess I should try to through somthing together just to see if it has any positive effect on the "Hinge".DZ

Vyger, 'F'

"The Special", 'SF'

'08 FJR1300Comment

-

Word of caution

TC - if you get around to trying some welding, watch out for fire. I was cleaning up the swing arm today on the resoration project I'm working on, and I must have taken about half a pound of old grease out of the drive side arm. This is the side with the grease fitting that really doesn't get grease to where it needs to be. All that grease that folks pump in there over the years is just sitting there.......Ken TalbotComment

-

Hey Ken,

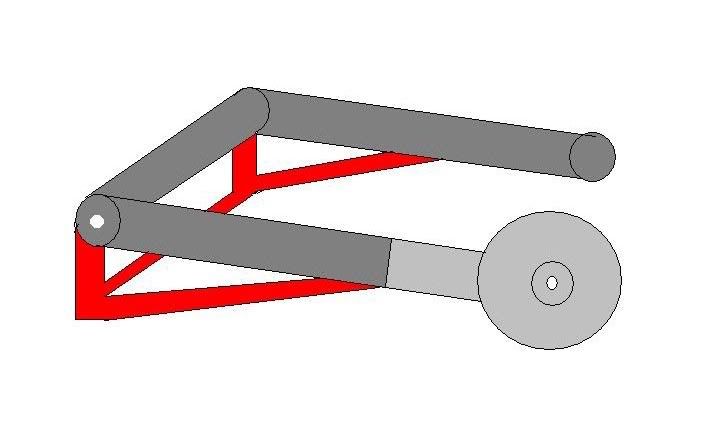

Thanks for the heads up, I think I would have realized that, but I might not have if you hadn't mentioned it! BTW, here's a little drawing that I think simulates the idea you had mentioned. Beside it is sorta what I had in mind, but along both top and bottom edges. I think adding some reinforcing along both sides should stiffen it up considerably, without the space/room problems inherent with your design!? I won't be doing this for a little while yet, but I'm pretty sure I'll be trying it!

T.C.

T. C. Gresham

81SH "Godzilla" . . .1179cc super-rat.

79SF "The Teacher" . . .basket case!

History shows again and again,

How nature points out the folly of men!Comment

-

Be careful with welding. As you weld, there is a lot of heat strain as you draw the bead. You can deform the structure as you weld from one one to the other and as the structure progressively cools. It won't look like a pretzel, but you can cause some deformation. I am not a welder per se, but I did scew up a bunch of trusses this way, long ago. The deformation made the trusses useless!

Originally posted by TopCatGr58

Hey Ken,

Thanks for the heads up, I think I would have realized that, but I might not have if you hadn't mentioned it! BTW, here's a little drawing that I think simulates the idea you had mentioned. Beside it is sorta what I had in mind, but along both top and bottom edges. I think adding some reinforcing along both sides should stiffen it up considerably, without the space/room problems inherent with your design!? I won't be doing this for a little while yet, but I'm pretty sure I'll be trying it!

T.C.

Skids (Sid Hansen)

Down to one 1978 E. Stock air box with K&N filter, 81H pipes and carbs, 8500 feet elevation.Comment

-

I have a spare from an 80 Standard that I parted out. It's yours for shipping costs and I want pictures of the finished project...

Some years ago I saw pictures of a KZ1000 swingarm from a bike that Keith Code was racing. It had a tube structure welded to it that looked like a bridge. Maybe if you googled for swingarm mods you could find some pix...

GeezerHi my name is Tony and I'm a bikeoholic.

The old gray biker ain't what he used to be.Comment

-

Hey there Geezer,

Thanks for the offer, but John in Texas is a bit closer, and I was thinking of hitting him up for one so I could work on it while I could still ride mine, then do the swap out once I got the bracing done! Definitely, I'll be posting pictures!! After looking at it again on the bike, there's a ton of space in the corners, Yamaha put a modest brace in the right corner, but there's tons of room to add another one ontop/inside those corners, so I'll be having lots of FUN!! I'll try a google later, thanks for the idea!

T.C.T. C. Gresham

81SH "Godzilla" . . .1179cc super-rat.

79SF "The Teacher" . . .basket case!

History shows again and again,

How nature points out the folly of men!Comment

-

Sorry to revive an old thread.

I've been looking into purchasing an XS650 for the wife and performing some "slight" modifications (perhaps similar to this bike

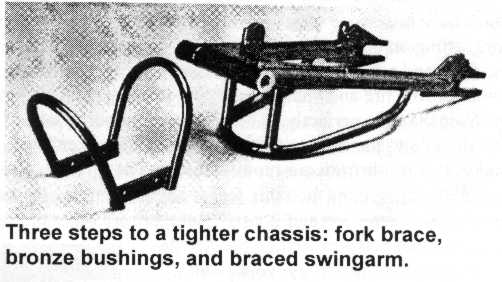

While perusing the info on the XS650, I came across an older mag article regarding a swingarm brace. Thought it may be good info here even though the 650 does not share the driveshaft in the swingarm ... or was it decided that the 1100 swingarm is too thin walled?

The article is located at

http://www.650central.com/ then scroll down the left pane to Minton Mods.Comment

-

Long awaited update!

Hey Brian, Ken, DennyZ, and other interested parties!

First, here's a photo from that 650 link about Swingarm bracing:

Well, I finally got around to playing with my swingarm, and got the courage up to remove the swingarm bearing bolts, and driveshaft! First, because of some rubbing with my oversized rear tire 140/90-16 vs. OEM 130/90-16 I was thinking about possibly modding the recess that is molded into the driveshaft portion of the swingarm! BUT....after removing same, and putting the shaft back in, backlighting, and viewing, I could see that there is really no room to compress that area any more, see below!

However, I did take my grinder and removed some high spots on that area that had incurred the rubbing! It is also my hope that the rubbing was due to the flexing of the swingarm with the increased load of riding 2 up and hitting the twisties!

So....I have taken some 1" square tubing, and cut it to make a simple triangle pattern on the side of each arm, and a rectangle across the bearing shaft length. The welds are a bit ugly, but hopefully it will provide the stiffening that I am looking for?

It's hanging in the garage now with a nice coat of basic black glossy Rustoleum rattle can paint on it with 2 of my 1000 watt work lights shining on it to try to help bake/cure the enamel on a little faster?? I'll be putting it back on tomorrow, and will then post a ride report. After I had done my trunk bag/rack and MikesXS coil/wire conversion, I took it out for a test run, and even though I was on a straight highway, it started to get that 90+mph wobble! Hopefully it won't be there after this!?

Hopefully it won't be there after this!?

T.C.T. C. Gresham

81SH "Godzilla" . . .1179cc super-rat.

79SF "The Teacher" . . .basket case!

History shows again and again,

How nature points out the folly of men!Comment

-

Somewhere else...

I saw a thread about replacing the rubber engine mounts with solid bushings and I think that probably is the best way to add strength to the frame. I have a '78 E and it doesn't exibit the problems I had with the '79 which were as you said, "speed and uneven corner means wobble". This one is stable as a rock and I ride the twisties like a sport bike on steroids dragging everything, even folding up the pegs on the right turns. Any actions like that with the '79 and I would surely be covered with road rash.......You can't stay young forever, but you can be immature for the rest of your life...

'78E "Pathfinder" Show bike...

Lovingly restored by Dave Delzell

Drilled airbox

Tkat fork brace

Hardly mufflers

late model carbs

Newer style fuses

Oil pressure guage

Custom security system

Stainless braid brake linesComment

-

As I understand it this is a reasonable fix and I intend to do this on the bike that will be for personal use. Watch your ground clearances and swing arm movement space and your good to go.

RobKEEP THE RUBBER SIDE DOWN

1978 XS1100E Modified

1978 XS500E

1979 XS1100F Restored

1980 XS1100 SG

1981 Suzuki GS1100

1983 Suzuki GS750S Katana

1983 Honda CB900 CustomComment

-

When using a wire feed welder, weave the bead side to side a little 1/16- 1/8 as you weld and you will get a better weld. Just trying to help. Great job & idea.79 F full cruiser, stainless brake lines, spade fuses, Accel coils, modded air box w/larger velocity stacks, 750 FD.

79 SF parts bike.Comment

-

?????

From an engineering standpoint, I see no advantage to this idea. There won't be any extra strength in that design. Only waakening of the existing metal by the welding process.You can't stay young forever, but you can be immature for the rest of your life...

'78E "Pathfinder" Show bike...

Lovingly restored by Dave Delzell

Drilled airbox

Tkat fork brace

Hardly mufflers

late model carbs

Newer style fuses

Oil pressure guage

Custom security system

Stainless braid brake linesComment

TC you'd smooth those welds easy, also there's thick syrup-like Por15 engine enamel, brush on as thick as required, sets hard too.

TC you'd smooth those welds easy, also there's thick syrup-like Por15 engine enamel, brush on as thick as required, sets hard too.

Comment