Question & Curiosity:

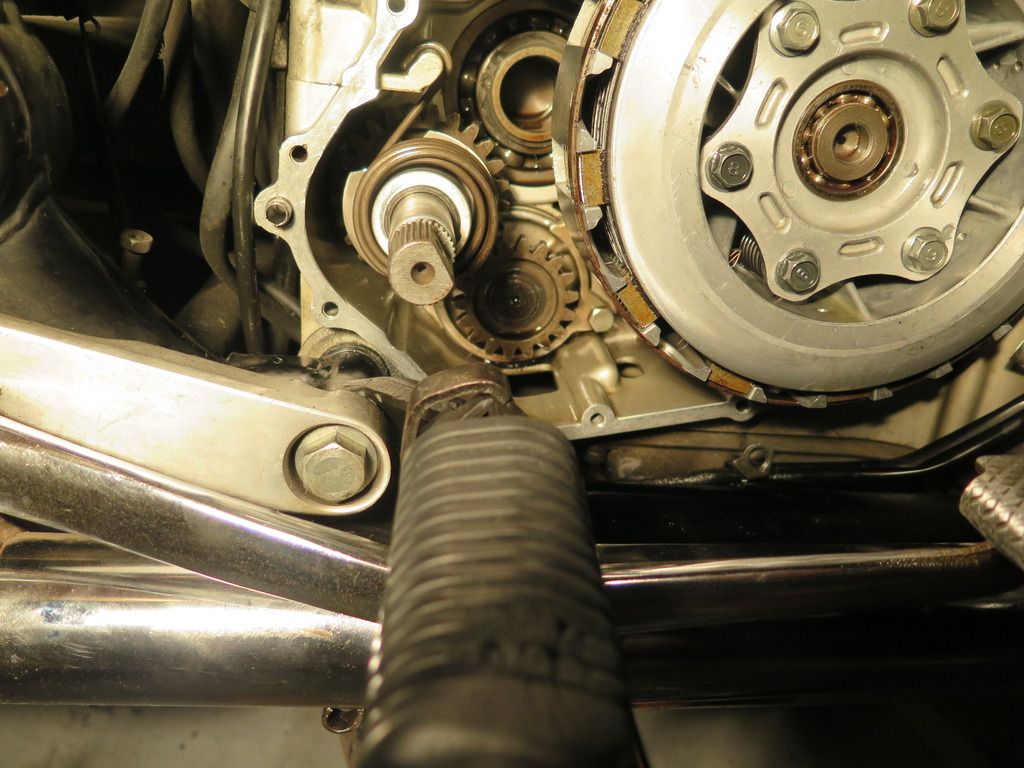

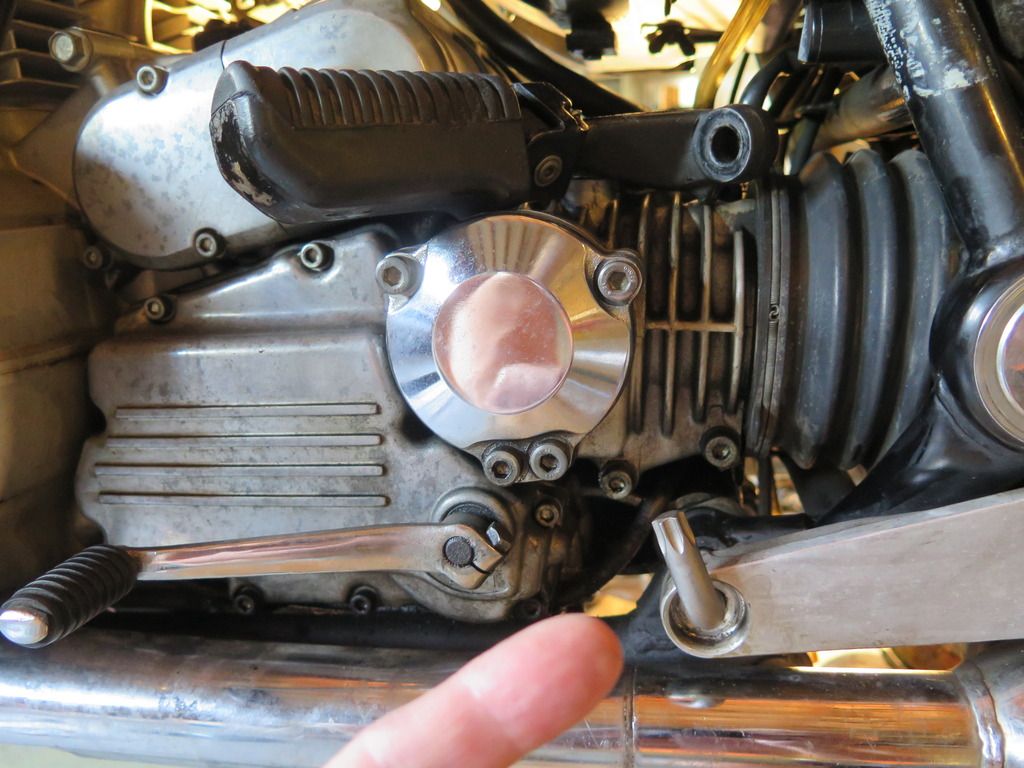

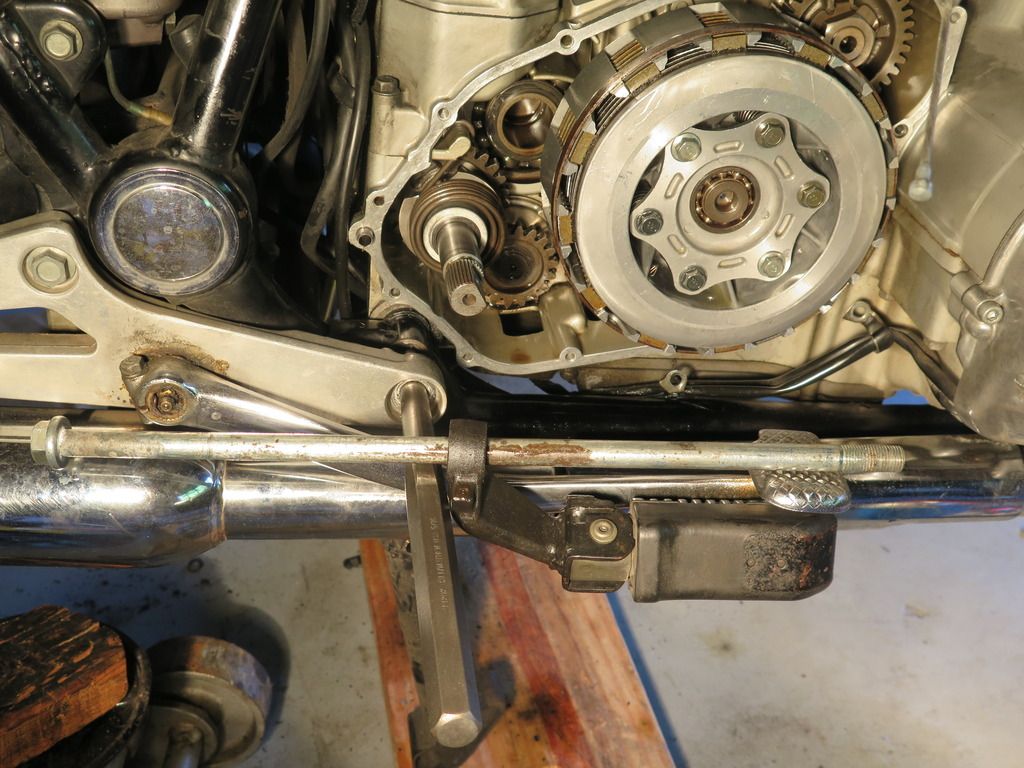

Did an R&R on the Clutch. Removed and measured the plates. But they were all bone dry as you can see in the photo. (btw: all plates in spec and almost exact thickness to my new plates)

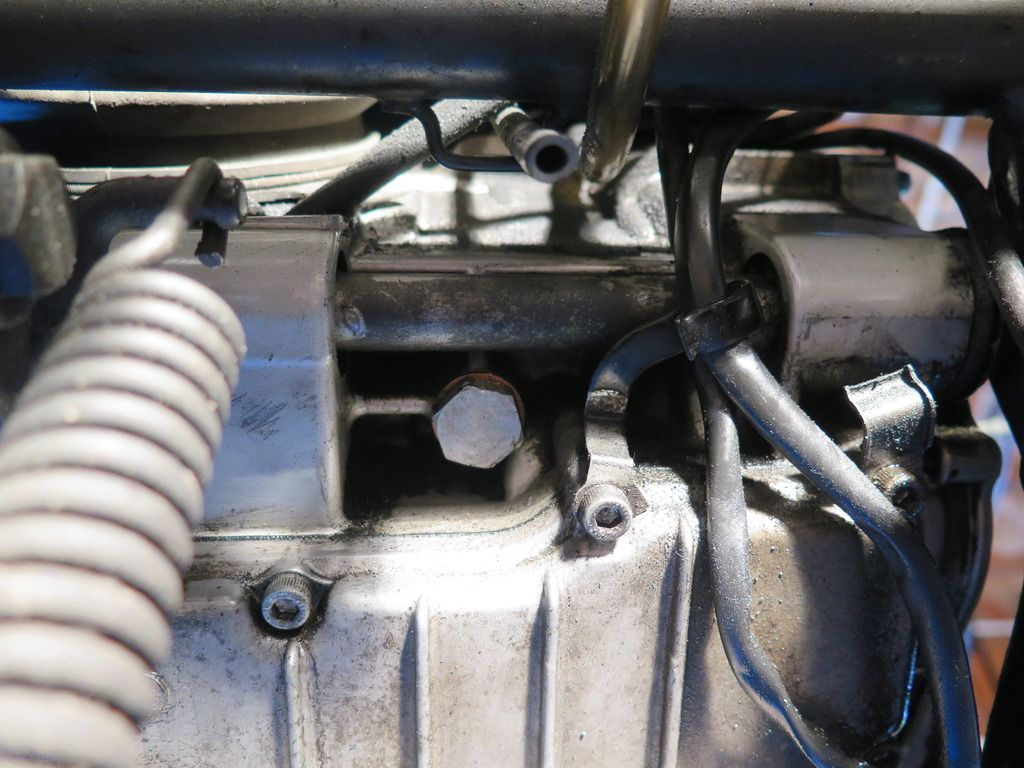

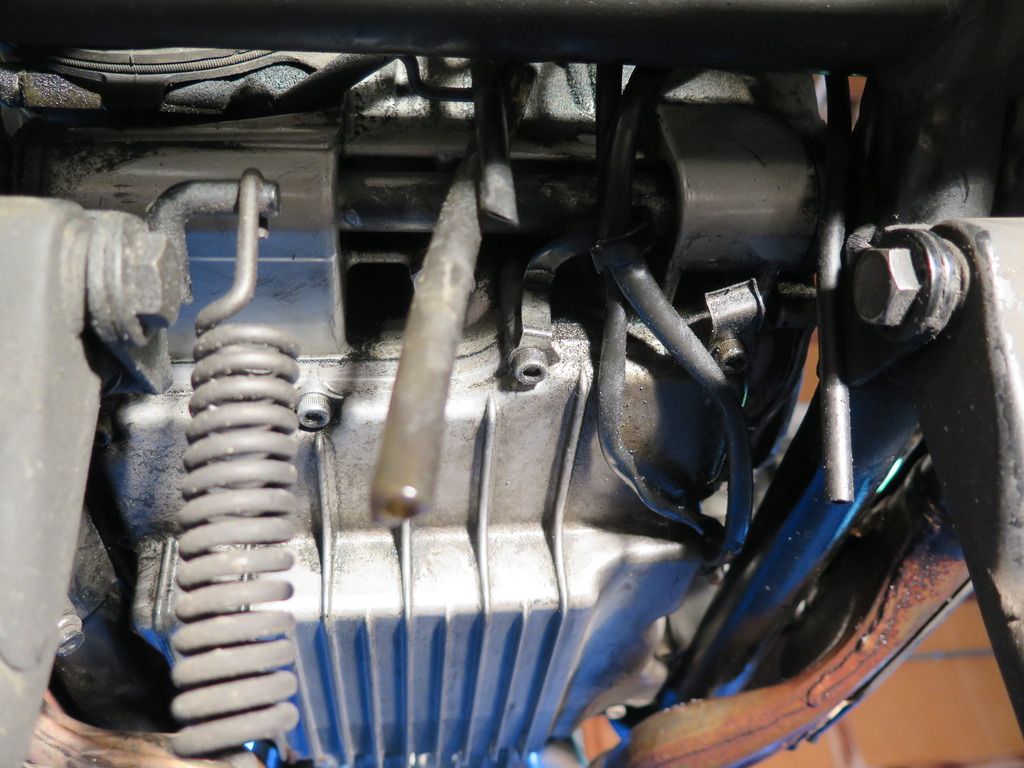

I had ridden the bike about 20 miles immediately prior to draining the oil and removing the clutch. Oil level was at the upper level in the sight glass. So oil was tip-top full. Looking at the side cover and the position of the clutch plates to the sight glass the plates would be bathed in say 1/4" of oil. Yet these plates were dry and oil free.

Clutch Plates that I removed from XS 11E. Are as-is not wiped off at all. Just dry & oil free.

Plates to the left nearest the engine. Plates going to right outward toward case

Marty stopped by today after work to say Hey and he handled the clutch plates and was surprised to have No Oil residue at all on his hands. Anybody have an explanation? That brown stuff is dry, not like a gummy varnish buildup. Also no real sign of any normal slippage as parts engage when taking off from a stop. Supposedly spinning in small amount of oil but whole clutch assembly & plates were dry within an hour of a 20 mile ride. Is this normal? BTW: using Yamaha 20-50 oil since I got the bike in 2012. Clutch actually was working quite well but I could feel it wasn't exactly right.

Thanks,

Jeff

Did an R&R on the Clutch. Removed and measured the plates. But they were all bone dry as you can see in the photo. (btw: all plates in spec and almost exact thickness to my new plates)

I had ridden the bike about 20 miles immediately prior to draining the oil and removing the clutch. Oil level was at the upper level in the sight glass. So oil was tip-top full. Looking at the side cover and the position of the clutch plates to the sight glass the plates would be bathed in say 1/4" of oil. Yet these plates were dry and oil free.

Clutch Plates that I removed from XS 11E. Are as-is not wiped off at all. Just dry & oil free.

Plates to the left nearest the engine. Plates going to right outward toward case

Marty stopped by today after work to say Hey and he handled the clutch plates and was surprised to have No Oil residue at all on his hands. Anybody have an explanation? That brown stuff is dry, not like a gummy varnish buildup. Also no real sign of any normal slippage as parts engage when taking off from a stop. Supposedly spinning in small amount of oil but whole clutch assembly & plates were dry within an hour of a 20 mile ride. Is this normal? BTW: using Yamaha 20-50 oil since I got the bike in 2012. Clutch actually was working quite well but I could feel it wasn't exactly right.

Thanks,

Jeff

.(worked well for me).

.(worked well for me).

Comment