I'm sure there's a lot of us that have the same problem - cracked, dry, deteriorated battery terminal boots. It's not like they really do much, but every time I look at one in that condition it kind of bugs me. But fear not gentle readers, I've got a fix for you.

I took a spark plug wire distributor boot out of a set of universal wires I used to do my coils, opened the plug wire end up with a 3/8" drill bit, and snipped off about 1/4" of the part that's supposed to go over the distributor terminal, put a little WD40 on the rubber part of the wire, slipped the boot over it, and voilà - brand new battery terminal boot for zero dollars and zero cents.

If I have to do it again - which I will on Betsy - I'll cut the distributor part of the boot back flush with the underside of the "wire end". But this is my brother's bike, and if he wants it perfect he can pull the terminal back off and fix it. And I'm positive this would work for the boot on the other side of that short wire too.

And I'm positive this would work for the boot on the other side of that short wire too.

Here's a few pics -

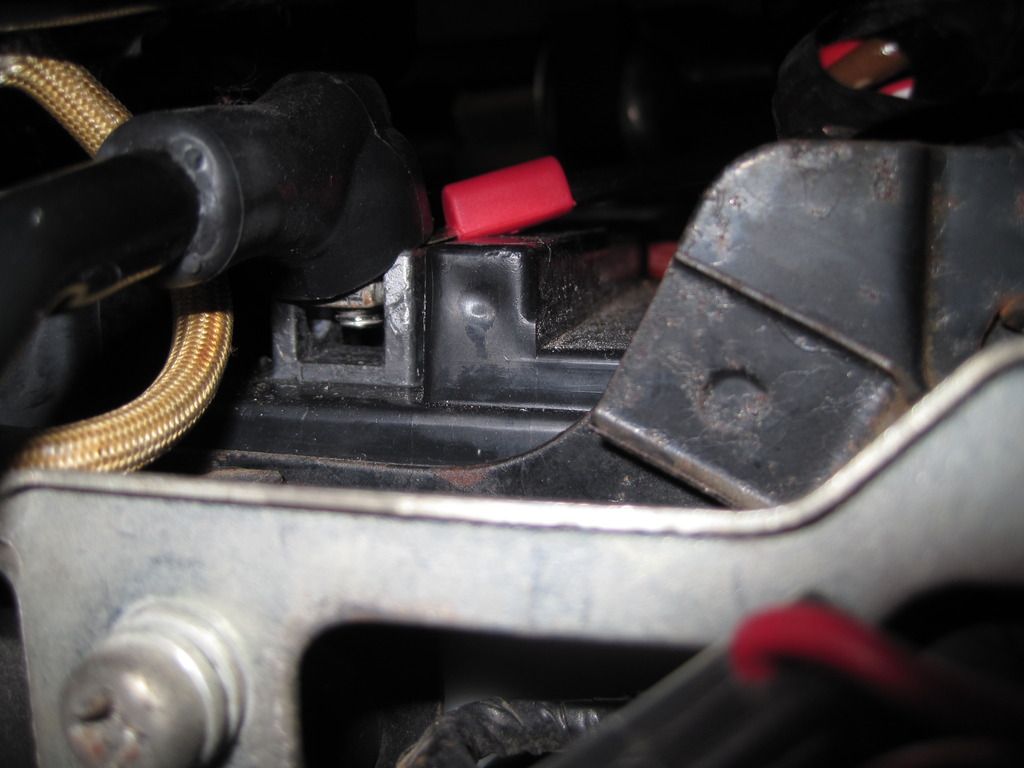

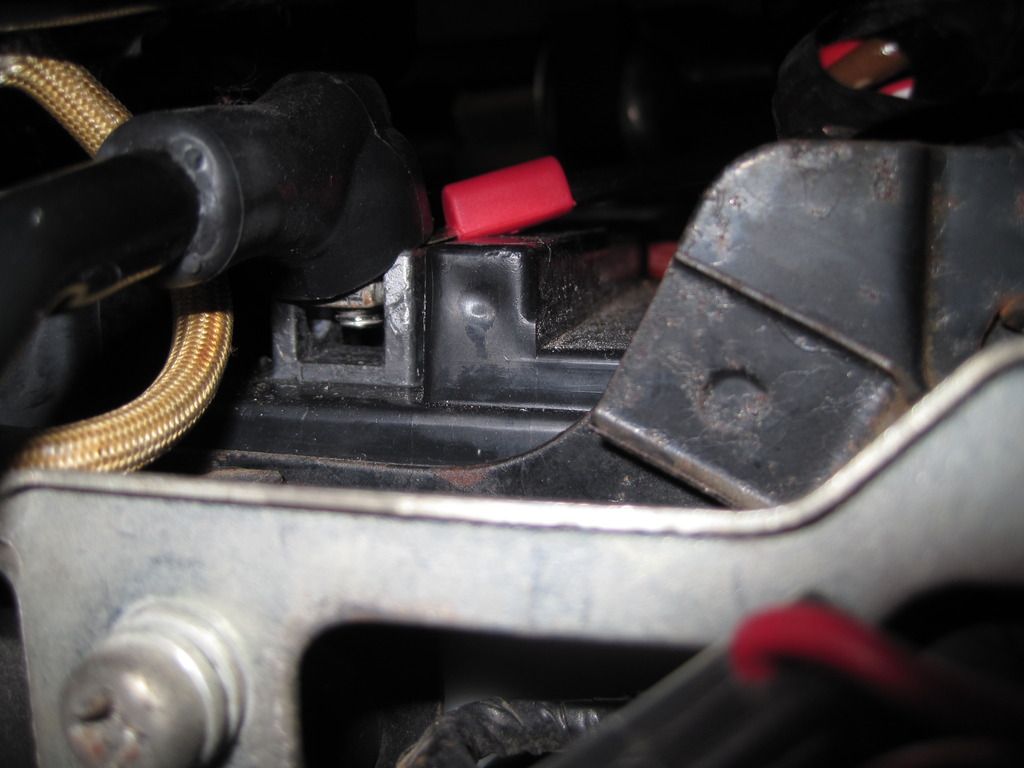

Here's the old, cracked, nasty looking boot

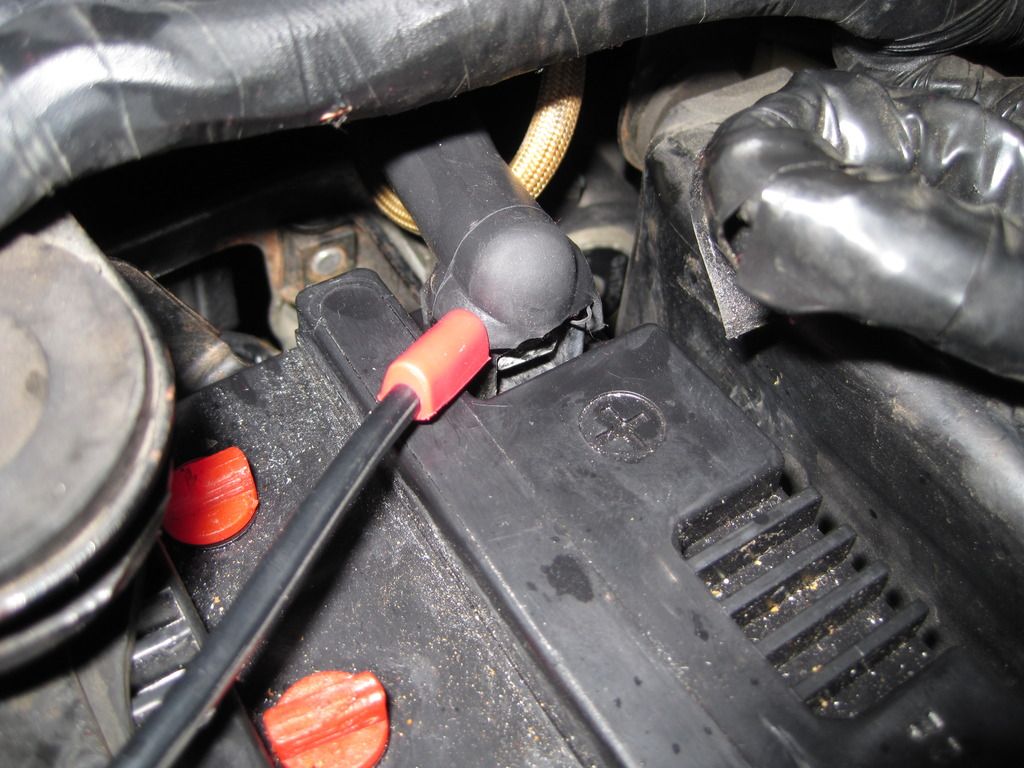

And here's the shiny, clean, nice, pretty, new one

I took a spark plug wire distributor boot out of a set of universal wires I used to do my coils, opened the plug wire end up with a 3/8" drill bit, and snipped off about 1/4" of the part that's supposed to go over the distributor terminal, put a little WD40 on the rubber part of the wire, slipped the boot over it, and voilà - brand new battery terminal boot for zero dollars and zero cents.

If I have to do it again - which I will on Betsy - I'll cut the distributor part of the boot back flush with the underside of the "wire end". But this is my brother's bike, and if he wants it perfect he can pull the terminal back off and fix it.

And I'm positive this would work for the boot on the other side of that short wire too.

And I'm positive this would work for the boot on the other side of that short wire too.Here's a few pics -

Here's the old, cracked, nasty looking boot

And here's the shiny, clean, nice, pretty, new one

.

.

.

.

Comment