Obviously I need more things to work on, I keep finding reasons to tear apart my spare parts just for S&Gs.

The starter clutch is one of those hardly ever a problem items on these bikes. So it is not often explored. I wanted a better understanding of exactly what goes on in there myself, so I took my spare primary shaft and started disassembly. I will not go into how to get the primary shaft out, as that involves splitting the engine cases.

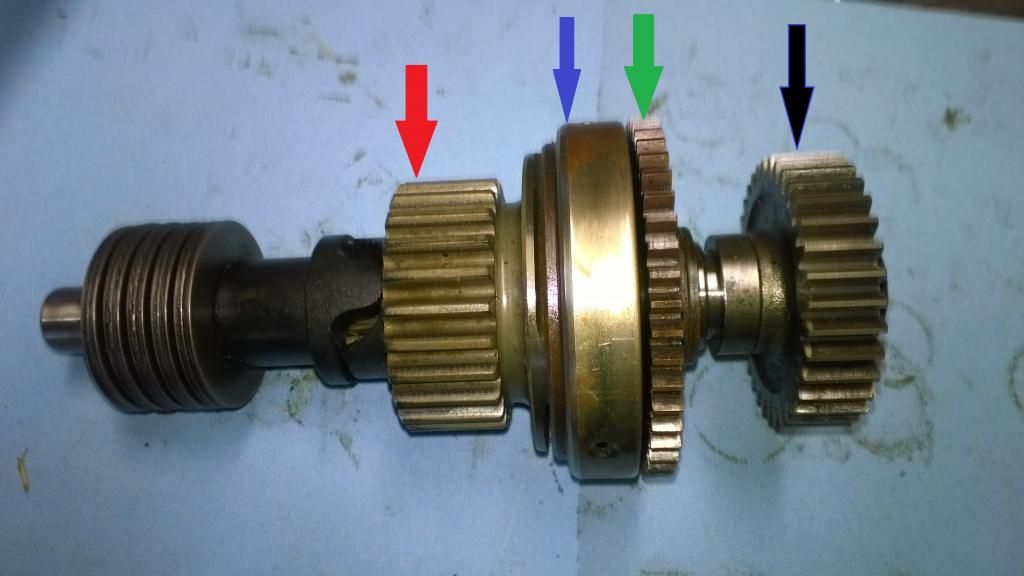

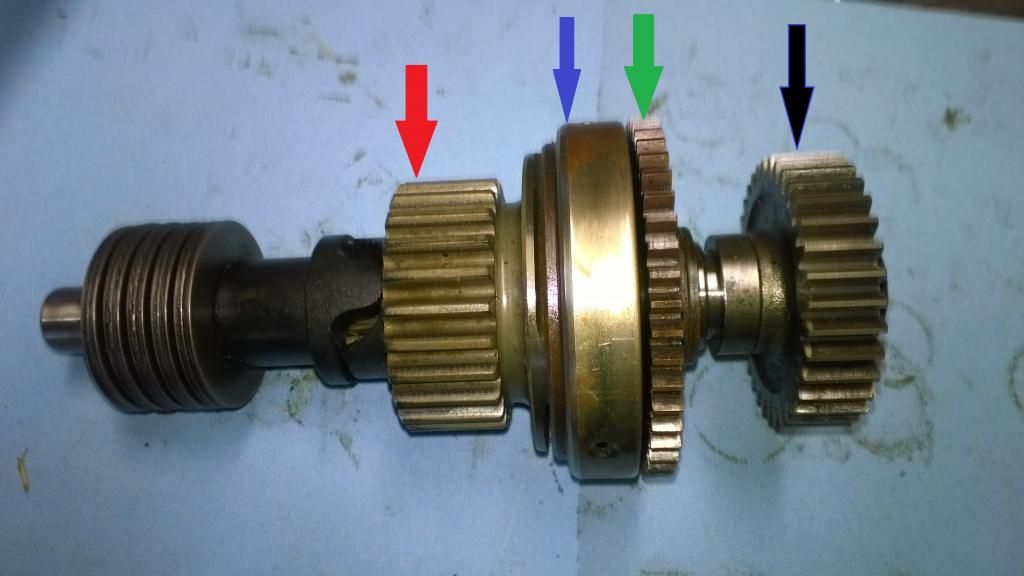

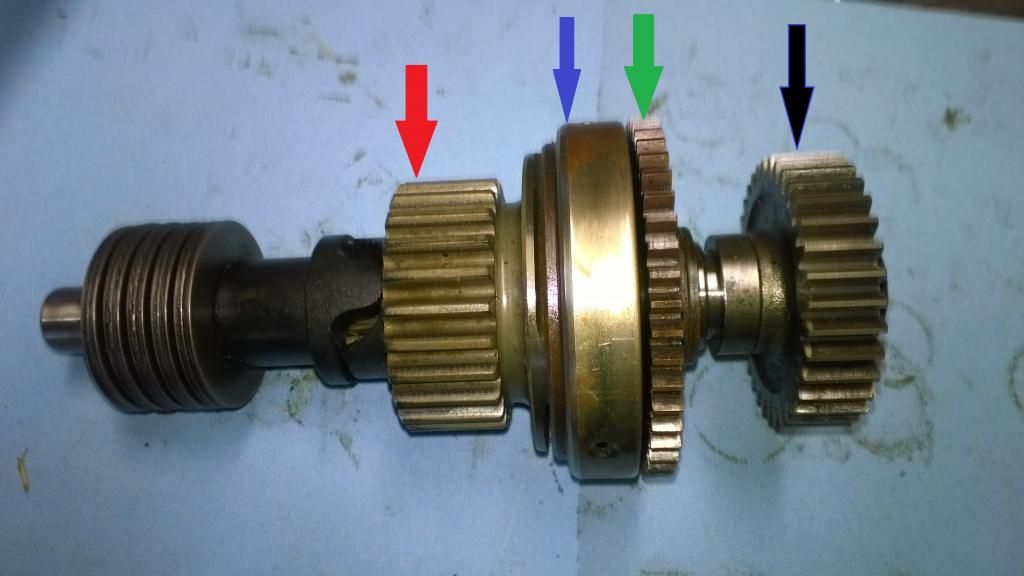

Here you have the primary shaft. Red arrow is where the Hyvo chain connects, it is turned directly by the crankshaft. Primary and Crank turn at the same time, always! There is a mechanism in the shaft to absorb some of the force and any uneven rotation to the left in this photo. The blue arrow is the starter clutch, the green arrow is the gear that mates with the starter, so when it turns, the starter turns, and vice-versa. Black arrow is the gear that drives the main transmission shaft.

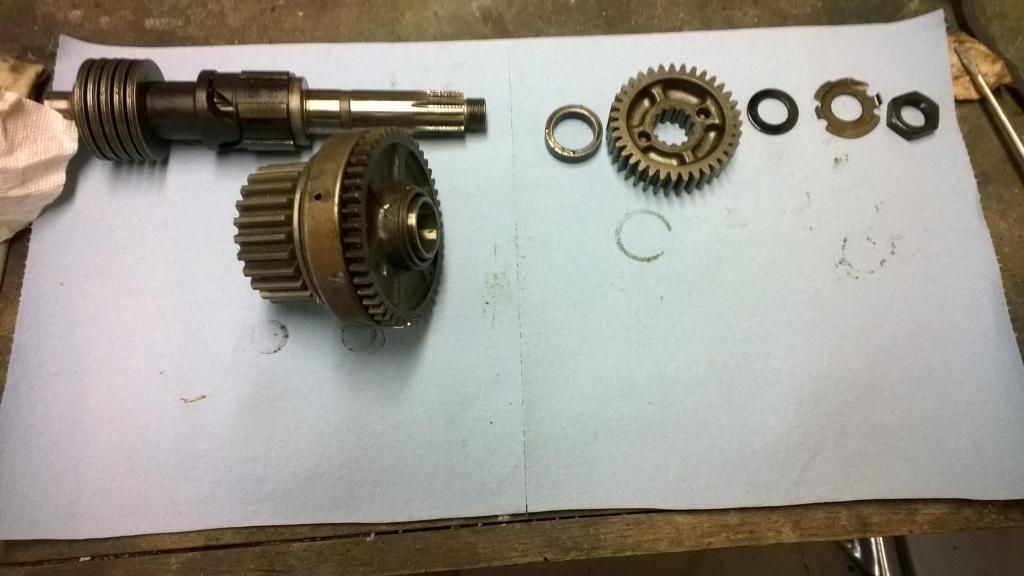

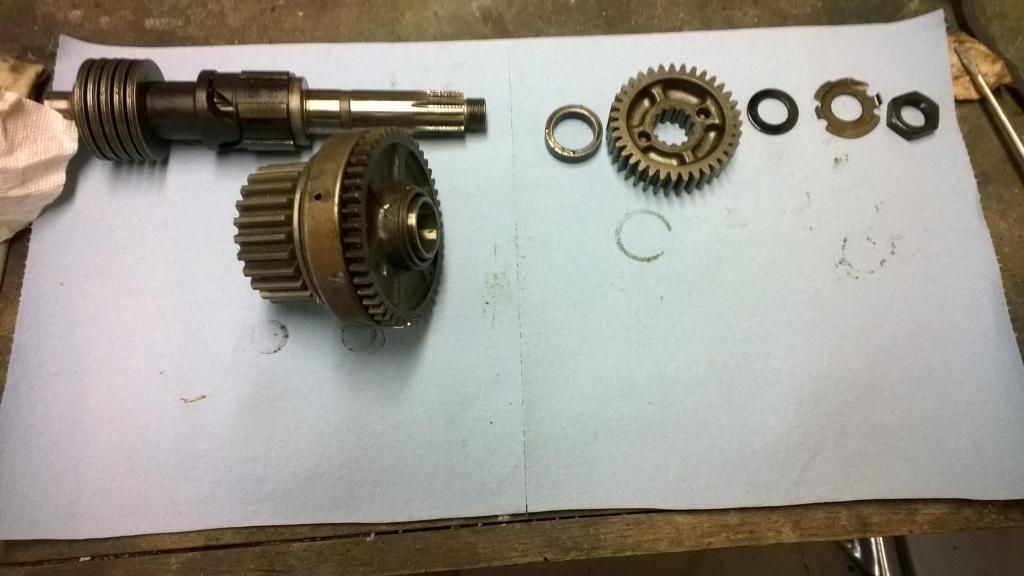

Here you see the components removed from the shaft. Simply unscrew the nut on the end, and the rest of the parts will slide off. I used the starter clutch assembly as a slide hammer to knock that other gear off the shaft.

From here the gear that engages the starter simply slides up out of the starter clutch assembly. It has a bearing shaft it rides on. It is not mated to the primary shaft, it spins freely separate from the primary shaft.

Here you see the three 6mm hex head bolts that hold the starter clutch together. They are peened to the assembly on the other side, making them a PITA to break free.

This is how I got them loose. The jaws on the vice are below the gear and grabbing a non critical area on the shaft. They were still VERY tough to get turning.

Now the Hyvo gear lifts off, with its little collar between the gear and the starter clutch.

Now you can see the starter clutch pawls, and the spring loaded plunger pushing them toward engaging.

Here is an overhead after the cover plate has been removed (Note, the plate is marked which side goes toward the gear). If you look at the slot they sit in, it narrows, tightening the space between it and the primary shaft.

The pawls simply lift out, and the plungers will then pull out along with their springs. A rebuild kit comes with new springs, plungers and pawls.

Ok, so now that we have seen the innerds of this thing, how does it work?? Lets go back to the first picture. The left side of this picture is the left side of the engine. The Hyvo chain turns the shaft clockwise looking from the left side.

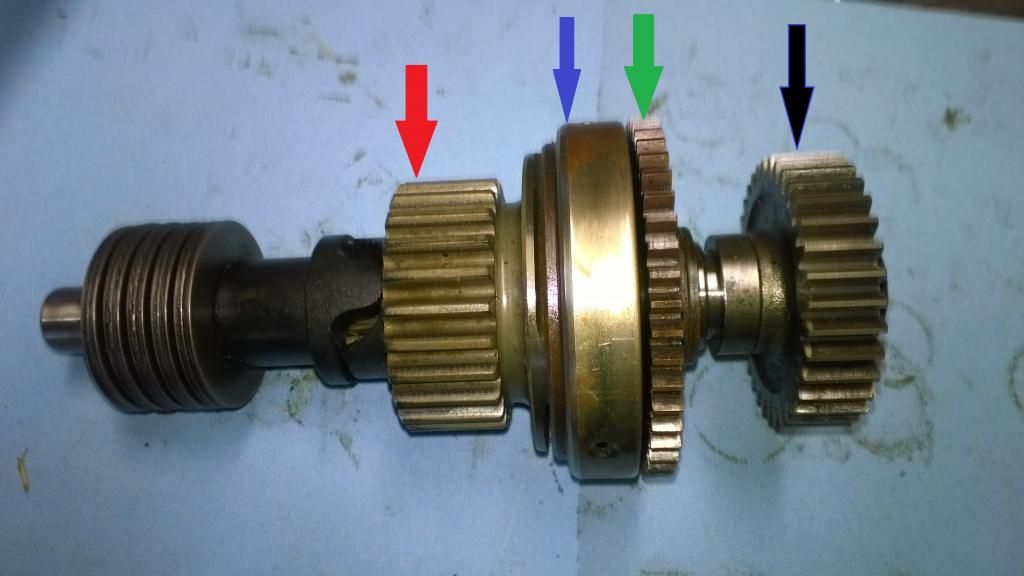

So, looking again at the slots in the starter clutch, recalling your looking at the Hyvo gear side of the starter clutch assembly, this direction of rotation forces the pawls to the left as shown in this picture. Opening up the slot letting the pawls rotate and not bind with the shaft, or grab the starter gear. So when the starter is not engaged, and the engine is running, the starter gear can sit idle as the engine spins.

Now when the engine is not turning, and you hit the starter button, the starter gear is turned, and in that case, the pawls are being forced toward the right side in the photo above, narrowing the space between the starter clutch and the starter gear. This causes them to bind and lets the starter turn the primary shaft, and therefore the engine by way of the Hyvo chain. As soon as the engine speed exceeds the starter speed, the starter clutch will release the starter gear as those pawls go back the other direction to the wider end of the slot.

Hopefully that helps someone understand how that funky thing called the starter clutch works.

The starter clutch is one of those hardly ever a problem items on these bikes. So it is not often explored. I wanted a better understanding of exactly what goes on in there myself, so I took my spare primary shaft and started disassembly. I will not go into how to get the primary shaft out, as that involves splitting the engine cases.

Here you have the primary shaft. Red arrow is where the Hyvo chain connects, it is turned directly by the crankshaft. Primary and Crank turn at the same time, always! There is a mechanism in the shaft to absorb some of the force and any uneven rotation to the left in this photo. The blue arrow is the starter clutch, the green arrow is the gear that mates with the starter, so when it turns, the starter turns, and vice-versa. Black arrow is the gear that drives the main transmission shaft.

Here you see the components removed from the shaft. Simply unscrew the nut on the end, and the rest of the parts will slide off. I used the starter clutch assembly as a slide hammer to knock that other gear off the shaft.

From here the gear that engages the starter simply slides up out of the starter clutch assembly. It has a bearing shaft it rides on. It is not mated to the primary shaft, it spins freely separate from the primary shaft.

Here you see the three 6mm hex head bolts that hold the starter clutch together. They are peened to the assembly on the other side, making them a PITA to break free.

This is how I got them loose. The jaws on the vice are below the gear and grabbing a non critical area on the shaft. They were still VERY tough to get turning.

Now the Hyvo gear lifts off, with its little collar between the gear and the starter clutch.

Now you can see the starter clutch pawls, and the spring loaded plunger pushing them toward engaging.

Here is an overhead after the cover plate has been removed (Note, the plate is marked which side goes toward the gear). If you look at the slot they sit in, it narrows, tightening the space between it and the primary shaft.

The pawls simply lift out, and the plungers will then pull out along with their springs. A rebuild kit comes with new springs, plungers and pawls.

Ok, so now that we have seen the innerds of this thing, how does it work?? Lets go back to the first picture. The left side of this picture is the left side of the engine. The Hyvo chain turns the shaft clockwise looking from the left side.

So, looking again at the slots in the starter clutch, recalling your looking at the Hyvo gear side of the starter clutch assembly, this direction of rotation forces the pawls to the left as shown in this picture. Opening up the slot letting the pawls rotate and not bind with the shaft, or grab the starter gear. So when the starter is not engaged, and the engine is running, the starter gear can sit idle as the engine spins.

Now when the engine is not turning, and you hit the starter button, the starter gear is turned, and in that case, the pawls are being forced toward the right side in the photo above, narrowing the space between the starter clutch and the starter gear. This causes them to bind and lets the starter turn the primary shaft, and therefore the engine by way of the Hyvo chain. As soon as the engine speed exceeds the starter speed, the starter clutch will release the starter gear as those pawls go back the other direction to the wider end of the slot.

Hopefully that helps someone understand how that funky thing called the starter clutch works.

Well T.C., I wanted to think I had the gist, which is why I wouldn't think to roughen the pawl/cylinder, and instead the surfaces they should grab on.

Well T.C., I wanted to think I had the gist, which is why I wouldn't think to roughen the pawl/cylinder, and instead the surfaces they should grab on.

You did remove them in your 10 photo....and it looks like you can see a band of polishing in the channel....a closer view of that photo would be nice!

You did remove them in your 10 photo....and it looks like you can see a band of polishing in the channel....a closer view of that photo would be nice!

Comment