I'm trying to find a good way to take out the 3/4 pilot jets that are fully stuck in my 80G carbs. Unfortunately they're in there good and I don't think they're coming out in good shape. I also need two new float needle valves, but I'm unsure which one I should be getting.

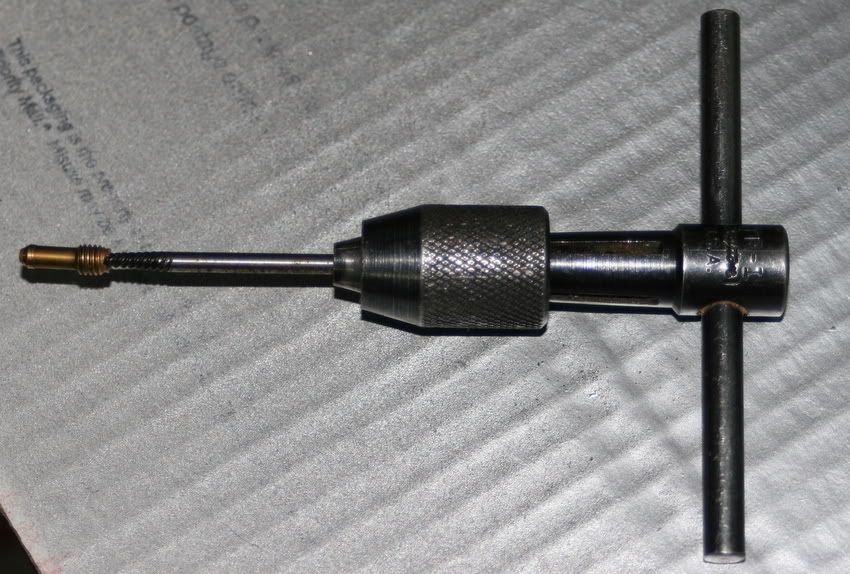

I saw in this thread that hbonser was having an issue as well. There were some suggestions of taking it out via a drill and a tap, a machine screw, etc, but I was still a little bit confused about what to actually do. I've also heard about using PB blaster to loosen things up or even boil outs where you remove everything that's not metal, soak the whole thing in gasoline overnight and light it on fire.

I feel like there has to be a better way to keep track of all this stuff rather than making a thread each time it comes up.

Additionally, adding some specifics on what parts each model carb uses would be great when we're trying to figure out what is supposed to go where.

Perhaps a sticky or a tech tip is in order?

I saw in this thread that hbonser was having an issue as well. There were some suggestions of taking it out via a drill and a tap, a machine screw, etc, but I was still a little bit confused about what to actually do. I've also heard about using PB blaster to loosen things up or even boil outs where you remove everything that's not metal, soak the whole thing in gasoline overnight and light it on fire.

I feel like there has to be a better way to keep track of all this stuff rather than making a thread each time it comes up.

Additionally, adding some specifics on what parts each model carb uses would be great when we're trying to figure out what is supposed to go where.

Perhaps a sticky or a tech tip is in order?

Comment