Having read several posts about fried connectors, misfiring cylinders in the rain, etc., brings something to mind that I had an experience with in the past that can and probably does relate to these problems.

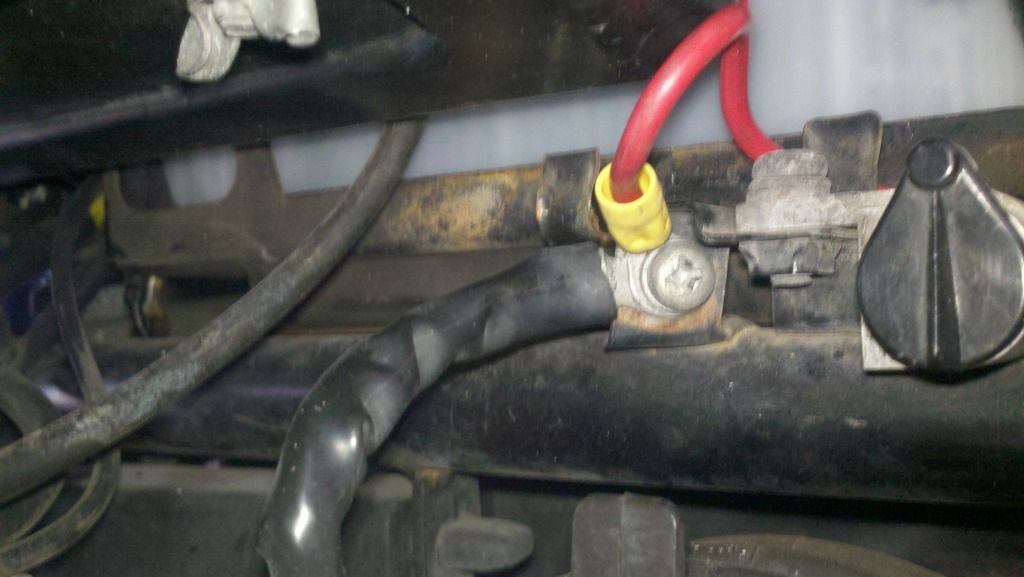

Our bikes, correct me if I am wrong, have the battery ground cable attached to the frame. Well, believe it or not, this is a POOR ground for most all of the electrics (including the spark plugs) on the entire bike.

An elctrical engineer/manufacturer acquaintance of mine and I went round and round a few years ago about battery ground.

He and is associates preformed a test with different metals to see which ones (if any) would equal the conductivity of a number 4 (0) gage copper wire. You may not believe it, but it took a piece of steel 1 and 1/2 inches in diameter and 18" inches long to equal the copper. I did not believe it either and told him so.

I was having a problem with an electric water pump (that he sold) with a rubber impeller that was continually melting the impeller.

His first question to me was "how is the pump grounded"? I said to the chassis. He said ground it directly to the battery and your problem will be solved? My brain was telling me that this guy is nuts. I asked him to explain and he obliged.

He first said look under the hood at any automobile or truck produced and you will see that the battery ground cable goes directly to the engine. All else except a few light bulbs ground from this point. He added that anything of significance i.e., electric pumps, motors, compressors, etc. grounded to the chassis rather to the battery will draw EXACTLY TWICE the number of amps that they were intended to. And furthermore, the spark plugs will fire with full energy as compared to a chassis ground.

In my case the water pump was drawing 14 amps instead of 7, overheating the armature, to which the melting impeller was attached, causing this failure. Guess what, I still didn't believe him. So I did it his way and................YES the problem was solved! YES I am a now a believer!

I have made it a point since to provide this proper ground to many, many applications which have equaled much impproved performance. Failures of this type for myself and others that I have changed disappeared.

Think about this. How is an engine grounded through rubber engine mounts without a ground cable going to it?

In conlusion, I believe that we could prevent many electrical failures, improve performance even further, and chase fewer ghosts, not to mention better battery charging, by simply improving the ground over the factory setup. I am going to do it to mine ASAP.

Thanks for listening and not falling asleep too many times.

MP

Our bikes, correct me if I am wrong, have the battery ground cable attached to the frame. Well, believe it or not, this is a POOR ground for most all of the electrics (including the spark plugs) on the entire bike.

An elctrical engineer/manufacturer acquaintance of mine and I went round and round a few years ago about battery ground.

He and is associates preformed a test with different metals to see which ones (if any) would equal the conductivity of a number 4 (0) gage copper wire. You may not believe it, but it took a piece of steel 1 and 1/2 inches in diameter and 18" inches long to equal the copper. I did not believe it either and told him so.

I was having a problem with an electric water pump (that he sold) with a rubber impeller that was continually melting the impeller.

His first question to me was "how is the pump grounded"? I said to the chassis. He said ground it directly to the battery and your problem will be solved? My brain was telling me that this guy is nuts. I asked him to explain and he obliged.

He first said look under the hood at any automobile or truck produced and you will see that the battery ground cable goes directly to the engine. All else except a few light bulbs ground from this point. He added that anything of significance i.e., electric pumps, motors, compressors, etc. grounded to the chassis rather to the battery will draw EXACTLY TWICE the number of amps that they were intended to. And furthermore, the spark plugs will fire with full energy as compared to a chassis ground.

In my case the water pump was drawing 14 amps instead of 7, overheating the armature, to which the melting impeller was attached, causing this failure. Guess what, I still didn't believe him. So I did it his way and................YES the problem was solved! YES I am a now a believer!

I have made it a point since to provide this proper ground to many, many applications which have equaled much impproved performance. Failures of this type for myself and others that I have changed disappeared.

Think about this. How is an engine grounded through rubber engine mounts without a ground cable going to it?

In conlusion, I believe that we could prevent many electrical failures, improve performance even further, and chase fewer ghosts, not to mention better battery charging, by simply improving the ground over the factory setup. I am going to do it to mine ASAP.

Thanks for listening and not falling asleep too many times.

MP

Comment