Today I rebuilt my leaky XS11 F model Front Brake Master Cylinder. Yamaha's Factory Service Manual has few details when servicing the master cylinder. Here's a few pics to assist the next forum member in making their ride stop as well as it goes. During this session I used the time to inspect the calipers & brake pads.

You'll need at least one pair of extended-reach snap ring pliers for the front master. These aren't easy to get out, particularly if they're rusted...

Besides what's noted in the pic, also note that this is a '78-79 Standard master. Completely different reservoir compared the later standards and specials with it's internal plate/screw mount, although they do share diaphrams/caps. The rear master reservoir on the '78-79 standards also mounts this way. Brass inserts to retain the cap, not found on the others.

To remove the brake light switch, press the tab you'll find in this hole.

A more typical front master (a Special in this case) with the reservoir removed. If you find any 'stuff' in the reservoir (congealed brake fluid, corrosion, etc), remove the reservoir and clean under it. I got nearly a teaspoons worth from under this one, and it looked clean! Twist and pull will remove most of them, the later rear masters have threaded studs so those you'll have to carefully pry up/off. You can clearly see the infamous 'splooge hole' here.

To check the rear splooge hole, remove this plug....

... and you'll be able to see it (barely). If your 'splooge hole' is clogged, it must be cleaned. More details here... http://www.xs11.com/forum/showthread.php?t=14. Best way to check if it's clear is to shine a light down the piston bore and look for light in the hole.

Typical innards with problem. Note that the last three items on the right may or may not be there; these are the outer dust seal, a nylon 'retaining ring', and a c-clip. The latter two may not be there at all or only one; there's also a dust seal type with a rigid ring built-in that doesn't use any retainer. Also note that the outer seal doesn't come in the aftermarket rebuild kits, only with the Yamaha kits ($$). This seal isn't absolutely needed, your call.

This is how the seal should be on the piston. I'll note here that you may not need a rebuild kit; if your seals still have a good 'flare' to them as seen here and aren't scratched/worn/ripped, you should be able to reuse them after cleaning everything. If the metal piston is rusty (particularly the part inside with the fluid), then you should replace; that rust will contaminate the system.

One question that comes up from time to time when owners check the parts diagram against what they get in a rebuild kit and ask 'what's that 'washer' between the two seals in the diagram?' Well, it's this 'star' washer and it's riveted to the piston, so look no further... Who knows why Yamaha shows it separate..

Who knows why Yamaha shows it separate..

Ok, you've got everything apart and cleaned, you're ready to put it back together. Or are you? If you found any corrosion or had to push/pull the piston out, there's a good chance the bore is rough. Without any seals, try dropping the piston in the bore. I'll also 'polish' the piston will some 0000 steel wool first to clean that. Does it slide right in without any pressure at all? If so, you're good. If not, you need to hone the bore...

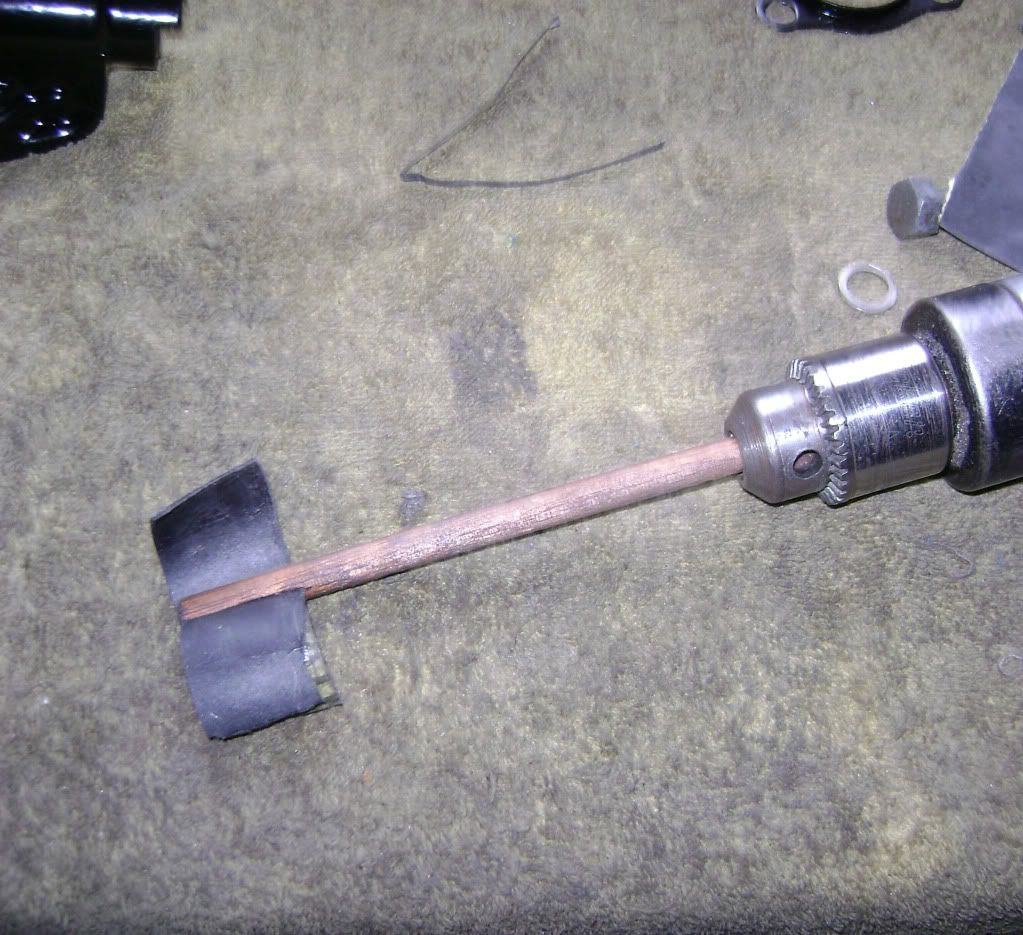

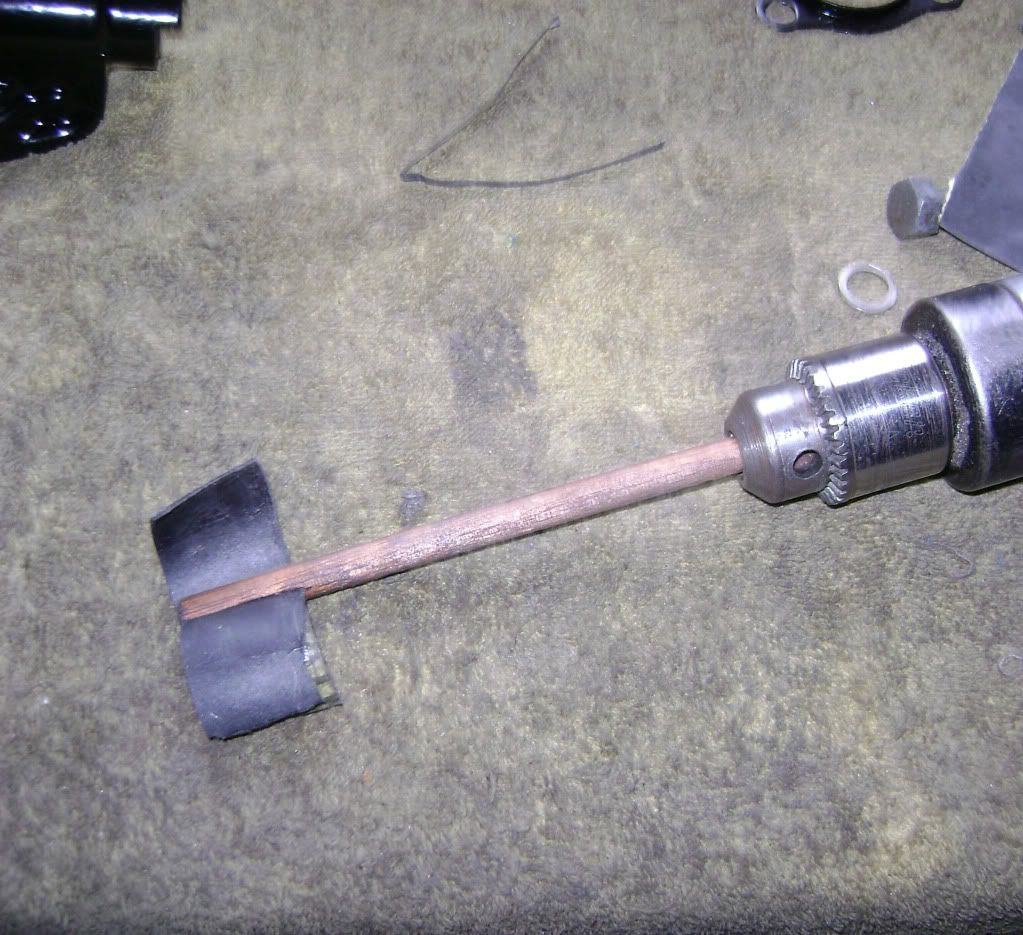

Homemade hone, nothing more than a piece of 3/8" wood dowling (don't use metal; it can scar the soft aluminum) with a slot cut in it. A small piece of used 600 grit sandpaper folded into a 'flapper' will do it. Give it 10-15 seconds at a time with some brake fluid or WD40 for 'cutting oil' until the piston will drop in of it's own weight. Now you can do your final clean...

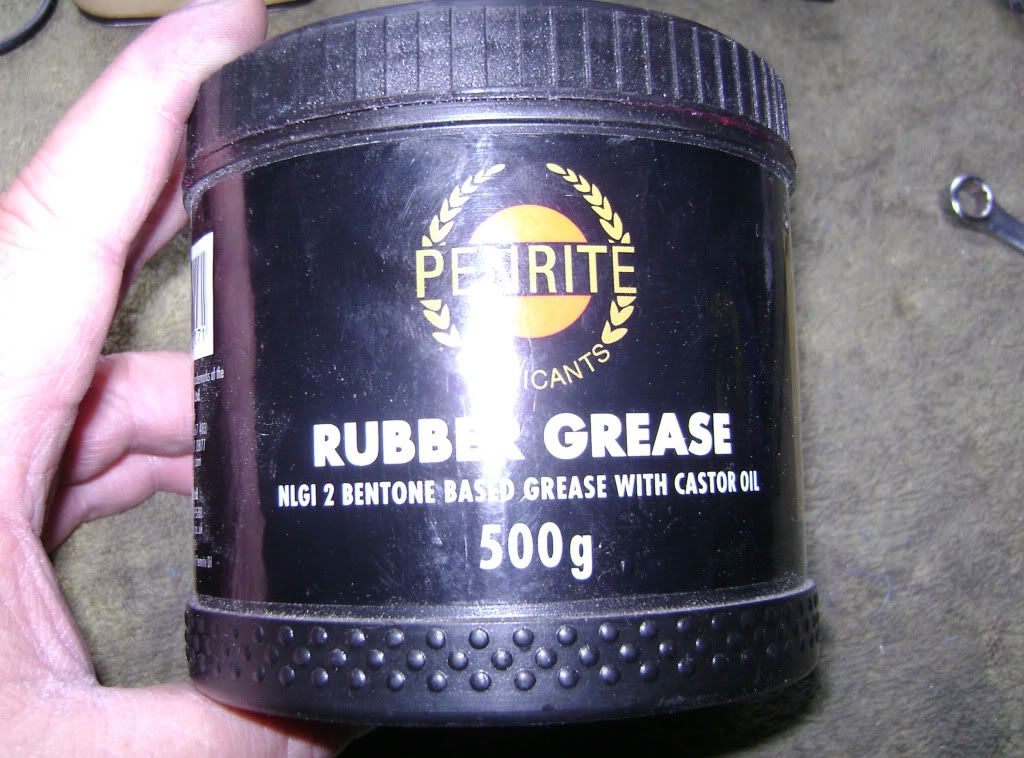

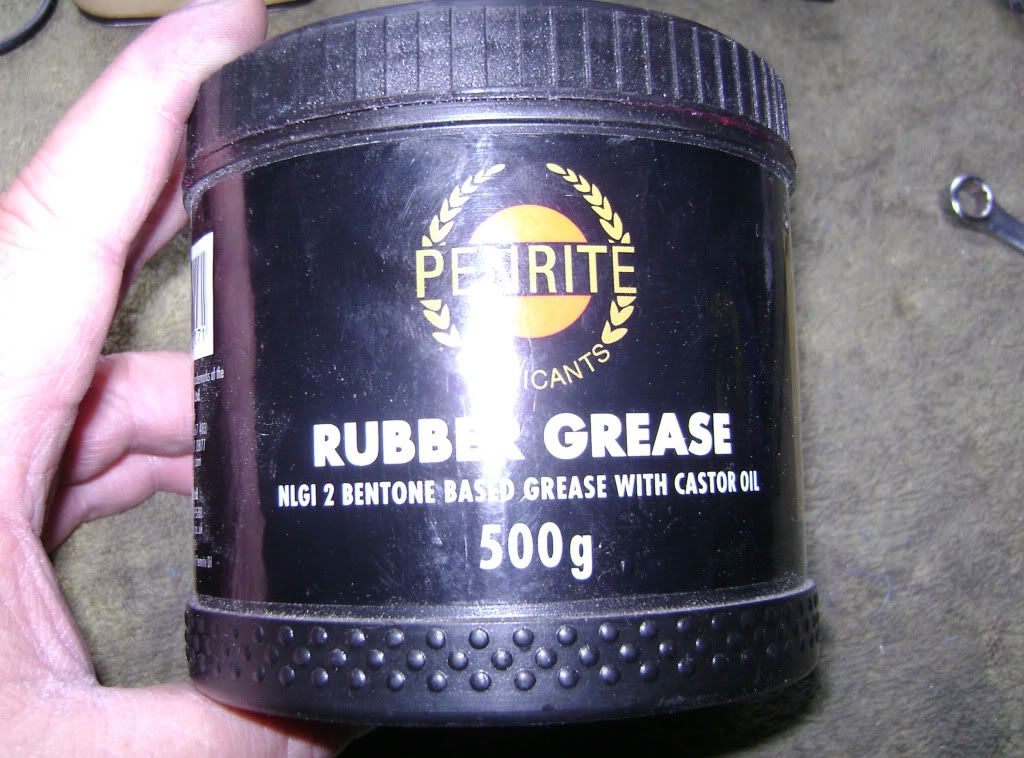

Here's an optional item, but worth it IMO. This is rubber grease; it's compatible with all hydraulic systems including brakes, and makes everything just slide together. If the parts are going to sit a while, it won't evaporate like brake fluid will. This is hard to find (eBay is the only place I've found this in the US), but is used by most OEM manufacturers and sometimes you'll get a little packet of it in brake rebuild kits (it's that red grease if you've run into it). I use this on all rubber brake fluid seals...

Install the piston, washer, and snap ring...

Dust seal if you have one...

One additional step I take before reinstalling the reservoir is to put a small amount of Yamabond where shown. Sometimes these will 'seep' a bit, this is easy insurance against that.

Last, but not least, remember to lube the brake lever pivot/bolt/small spring before re-installing the master cylinder.

Quick bleed tip: first affix m/c on handlebar. Apply gentle pressure on brake lever, loosen the banjo bolt slightly - let major air bubbles escape, then re-tighten the bolt, before jumping into bleeding the brake calipers. This move saves time and frustration if you do it correctly.

RJ

I've came back to this tip and heavily edited it to add more info and to show some of the differences you can run into. Except as noted below, the rebuild procedure is the same for both front and rear, all models; there will be minor differences in the appearance of some of the parts. Thanks to Rob for posting the original tip!

Crazy Steve

Crazy Steve

You'll need at least one pair of extended-reach snap ring pliers for the front master. These aren't easy to get out, particularly if they're rusted...

Besides what's noted in the pic, also note that this is a '78-79 Standard master. Completely different reservoir compared the later standards and specials with it's internal plate/screw mount, although they do share diaphrams/caps. The rear master reservoir on the '78-79 standards also mounts this way. Brass inserts to retain the cap, not found on the others.

To remove the brake light switch, press the tab you'll find in this hole.

A more typical front master (a Special in this case) with the reservoir removed. If you find any 'stuff' in the reservoir (congealed brake fluid, corrosion, etc), remove the reservoir and clean under it. I got nearly a teaspoons worth from under this one, and it looked clean! Twist and pull will remove most of them, the later rear masters have threaded studs so those you'll have to carefully pry up/off. You can clearly see the infamous 'splooge hole' here.

To check the rear splooge hole, remove this plug....

... and you'll be able to see it (barely). If your 'splooge hole' is clogged, it must be cleaned. More details here... http://www.xs11.com/forum/showthread.php?t=14. Best way to check if it's clear is to shine a light down the piston bore and look for light in the hole.

Typical innards with problem. Note that the last three items on the right may or may not be there; these are the outer dust seal, a nylon 'retaining ring', and a c-clip. The latter two may not be there at all or only one; there's also a dust seal type with a rigid ring built-in that doesn't use any retainer. Also note that the outer seal doesn't come in the aftermarket rebuild kits, only with the Yamaha kits ($$). This seal isn't absolutely needed, your call.

This is how the seal should be on the piston. I'll note here that you may not need a rebuild kit; if your seals still have a good 'flare' to them as seen here and aren't scratched/worn/ripped, you should be able to reuse them after cleaning everything. If the metal piston is rusty (particularly the part inside with the fluid), then you should replace; that rust will contaminate the system.

One question that comes up from time to time when owners check the parts diagram against what they get in a rebuild kit and ask 'what's that 'washer' between the two seals in the diagram?' Well, it's this 'star' washer and it's riveted to the piston, so look no further...

Who knows why Yamaha shows it separate..

Who knows why Yamaha shows it separate..

Ok, you've got everything apart and cleaned, you're ready to put it back together. Or are you? If you found any corrosion or had to push/pull the piston out, there's a good chance the bore is rough. Without any seals, try dropping the piston in the bore. I'll also 'polish' the piston will some 0000 steel wool first to clean that. Does it slide right in without any pressure at all? If so, you're good. If not, you need to hone the bore...

Homemade hone, nothing more than a piece of 3/8" wood dowling (don't use metal; it can scar the soft aluminum) with a slot cut in it. A small piece of used 600 grit sandpaper folded into a 'flapper' will do it. Give it 10-15 seconds at a time with some brake fluid or WD40 for 'cutting oil' until the piston will drop in of it's own weight. Now you can do your final clean...

Here's an optional item, but worth it IMO. This is rubber grease; it's compatible with all hydraulic systems including brakes, and makes everything just slide together. If the parts are going to sit a while, it won't evaporate like brake fluid will. This is hard to find (eBay is the only place I've found this in the US), but is used by most OEM manufacturers and sometimes you'll get a little packet of it in brake rebuild kits (it's that red grease if you've run into it). I use this on all rubber brake fluid seals...

Install the piston, washer, and snap ring...

Dust seal if you have one...

One additional step I take before reinstalling the reservoir is to put a small amount of Yamabond where shown. Sometimes these will 'seep' a bit, this is easy insurance against that.

Last, but not least, remember to lube the brake lever pivot/bolt/small spring before re-installing the master cylinder.

Quick bleed tip: first affix m/c on handlebar. Apply gentle pressure on brake lever, loosen the banjo bolt slightly - let major air bubbles escape, then re-tighten the bolt, before jumping into bleeding the brake calipers. This move saves time and frustration if you do it correctly.

RJ

Comment