Edited by Crazy Steve. Kat posted this originally (expanding it primarily with pictures on a tip posted by Maans Smit), but the original post only illustrated the late type carbs. So this is being edited/expanded once more to better cover both carb types; the '78-79 and '80-82. Make sure you watch for the differences, and I'd highly recommend that you look here: http://www.xs11.com/forum/showthread...811#post363811 first before starting your rebuild if you're not very familar with these carbs. The bulk of the pictures are of the late style carbs and there's not any major differences in the process, so don't be confused if your carb doesn't look exactly like the pic. There's also different schools of thought on whether or not to disassemble the individual carbs off the rack; there's pros and cons for both methods, but this will ultimately be up to you and what condition the carbs are in. This tip also won't get into jetting as that has just too many differences between types and how an individual bike may be set up; jetting guides will be found elsewhere in these tech forums or in the manual. With all this said, let's start....

Disassembling the carbs:

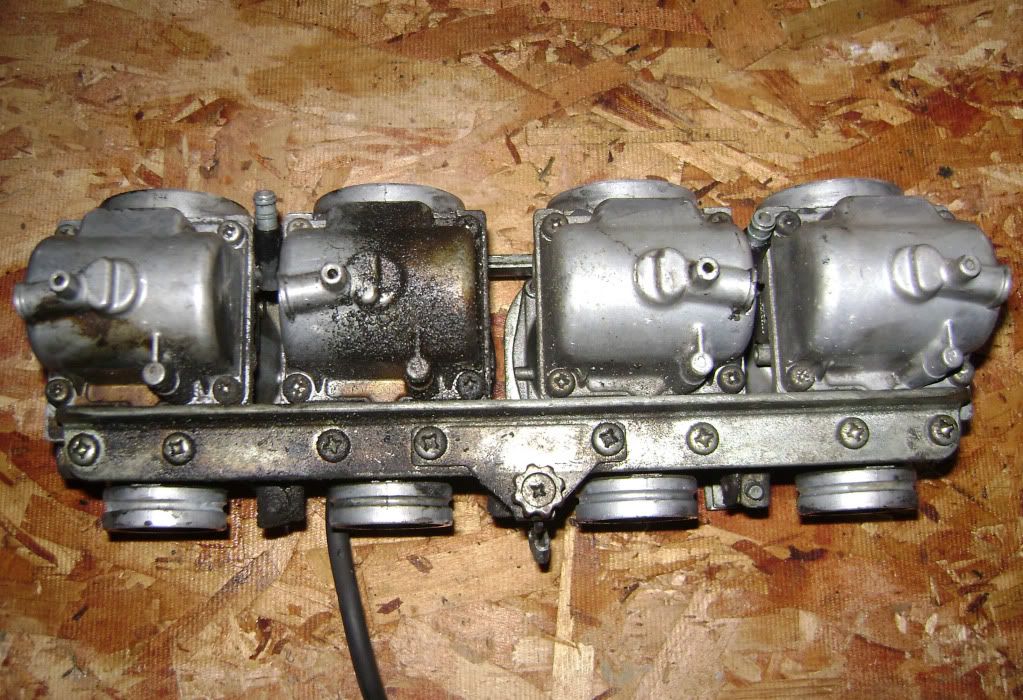

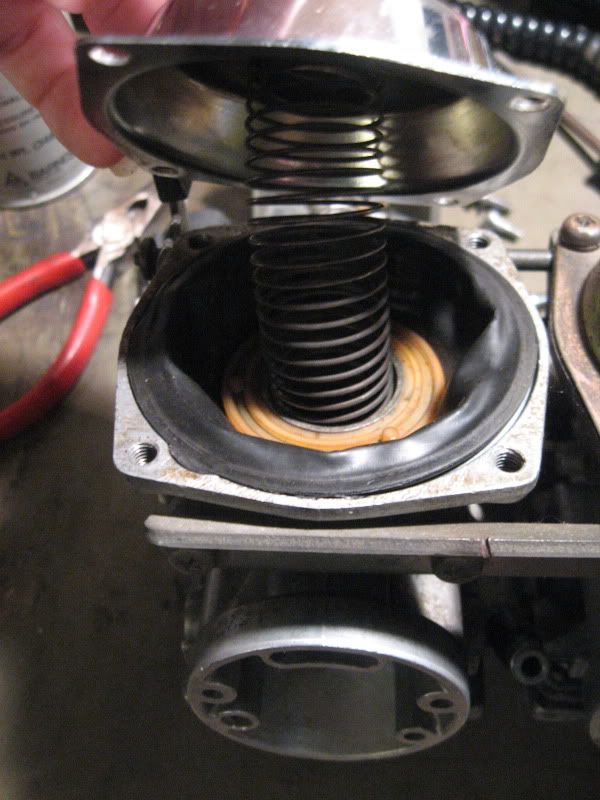

I like to work cleanly, so I usually first wash the gunk off the outside of the bank of carbs before I start removing parts. The main idea is to keep the insides of the four carbs separate. They should go back into the same carb they came out of unless a part needs to be replaced. So put them in front of you on a biggish piece of clean paper/cloth the way they sit in front of you on the scoot. No 1 on the left and 4 on the right. Now just turn the bank of carbs upside down.

First you're going to remove the float bowls which are the bottoms of the carbs. I like to first spray all screws/nuts/connections lavishly with PB Blaster or a similar product to make things easy. Note here these are '81-82 type bowls and are side-specific.

Unscrew the four Phillips (or whatever screws - mine came with Phillips and I replaced them with cap/Allen screws) on the corners of each float bowl, then carefully lift each one off. If the gasket comes out without tearing it may be able to be reused, otherwise you'll need a new one. Make sure you keep all internal parts with the carb body it was removed from.

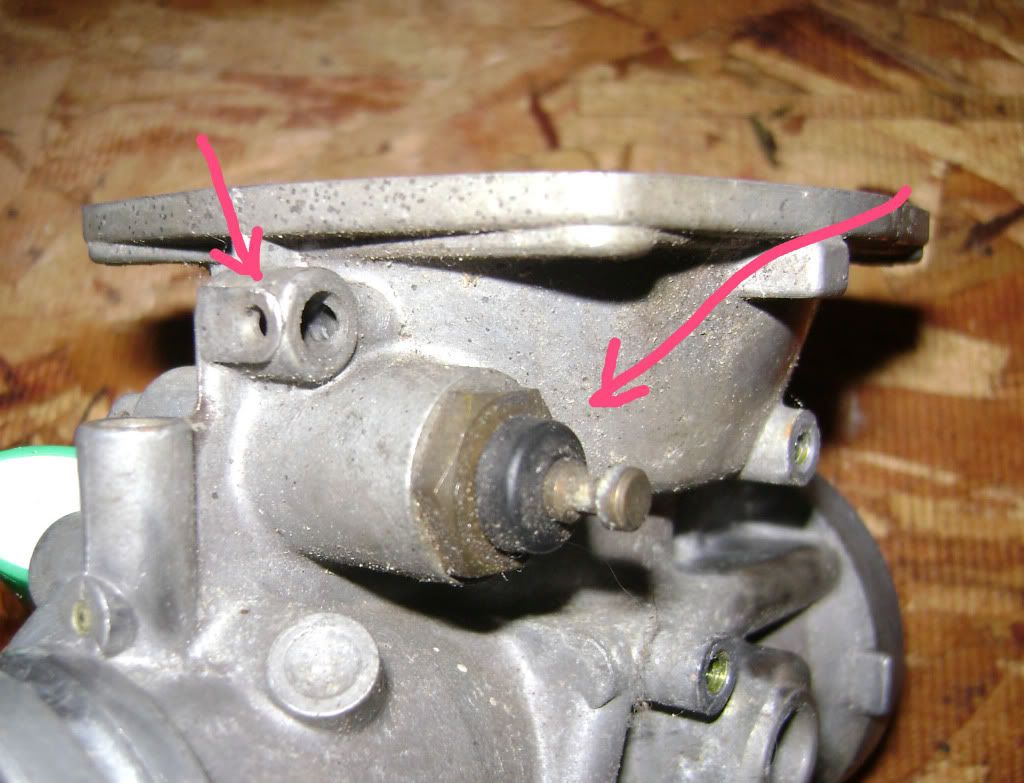

You'll see the float under the float bowl. It is held by a pin which goes through two posts which are part of the carb body. THOSE POSTS BREAK EASILY.

Again, those posts break easily. There's several methods for removing the float pin; you can use a sharp pair of wire cutters as shown but don't pry, just squeeze. You can also use a pair of needlenose pliers and grip the pin head, twisting while gently pulling outwards until the pin comes loose. Some have used a small nail or pin and lightly tapped from the end opposite the head, but use extreme caution if using this method as this is how many posts get broken. If you have an electric soldering iron (the larger the better), applying heat to the post with the pin head on it will help by expanding the aluminum a bit.

Lift the float and float needle up and off the carb. The late carbs have a viton-tipped needle that if the rubber is still resiliant can be reused. The early carbs will have a solid-steel needle. If the steel needle isn't worn, it can be polished and reused. Be aware that these are a leading cause of carb leaks, and it's hard to 'eyeball' these to tell if they're good. If you have doubts, I'd recommend replacement of both the needle and the seat.

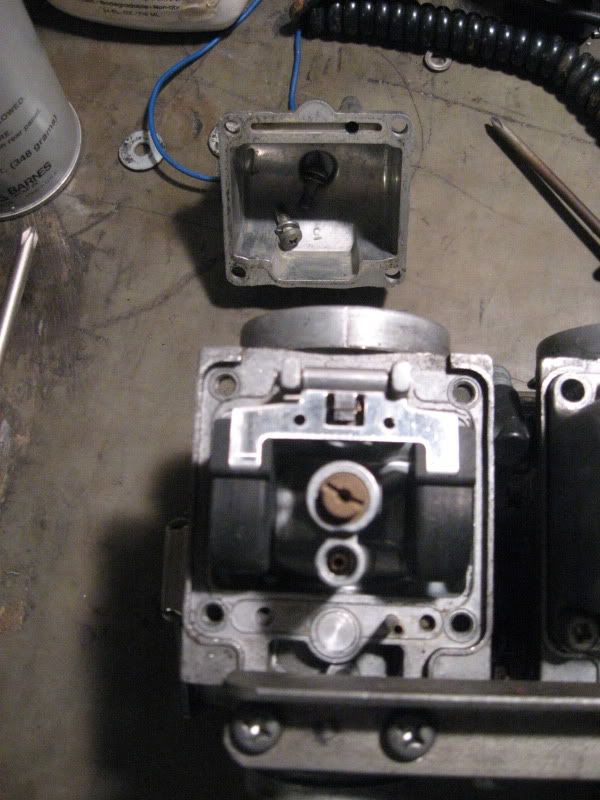

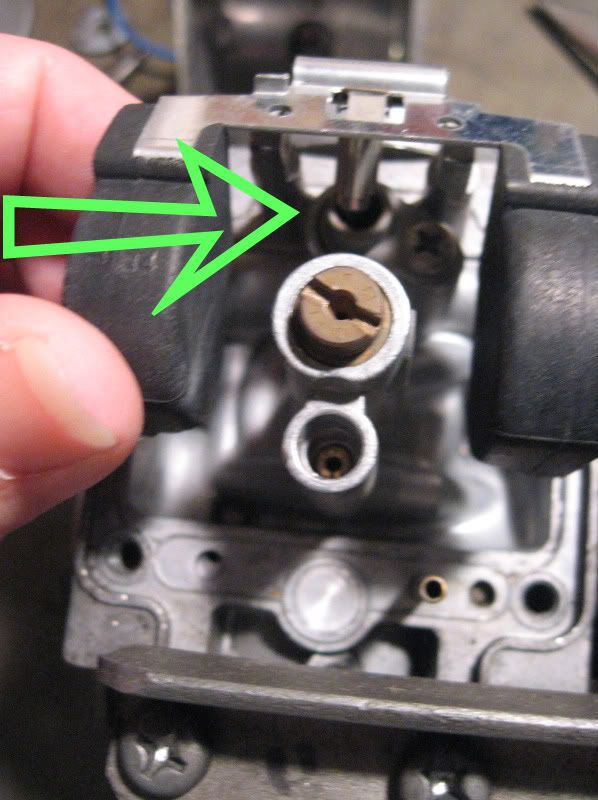

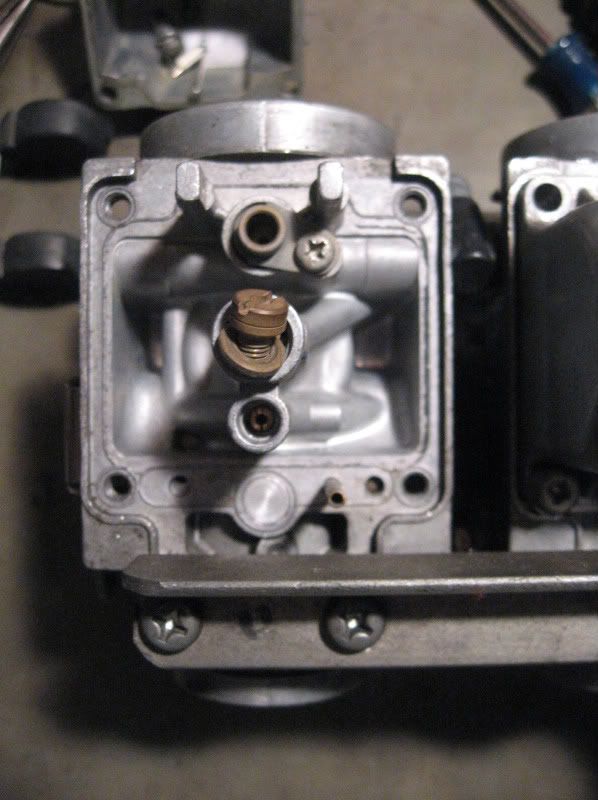

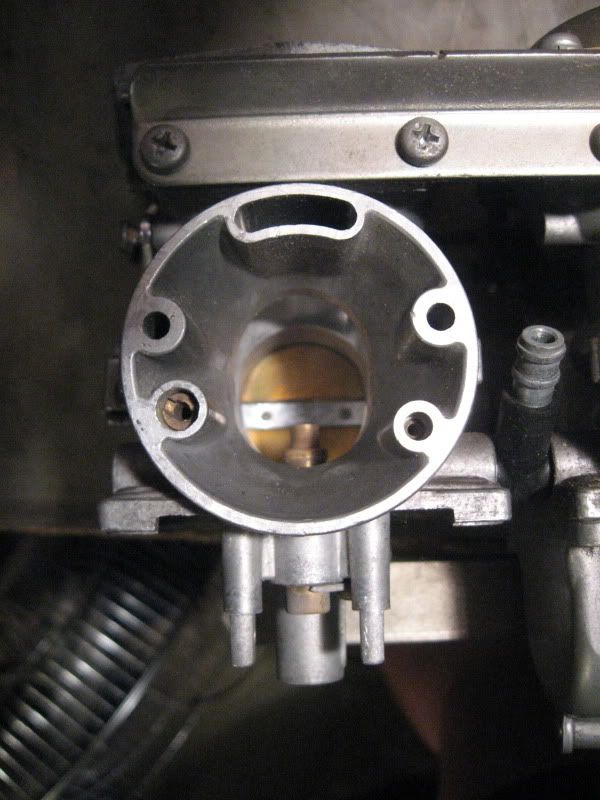

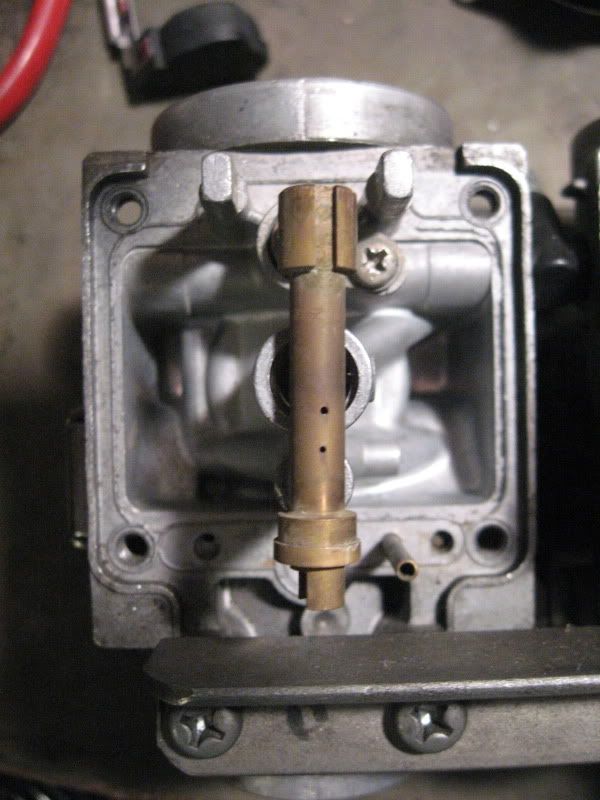

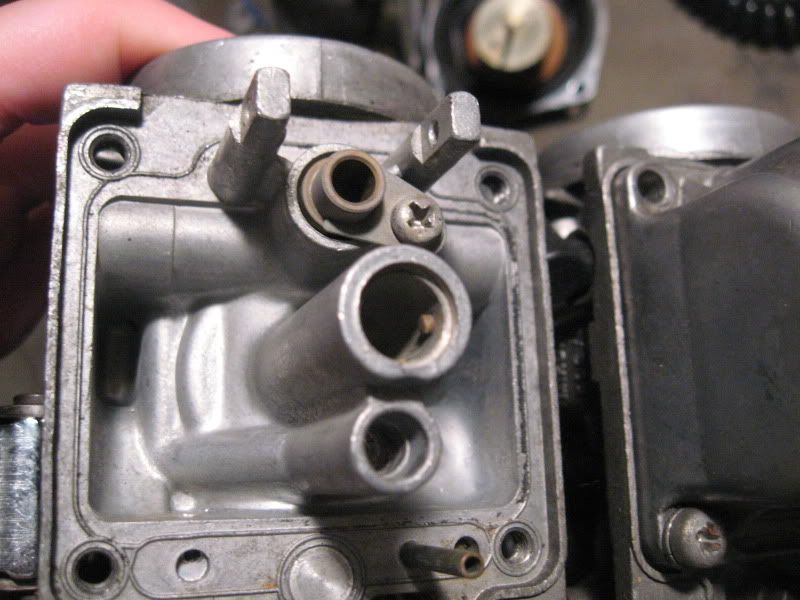

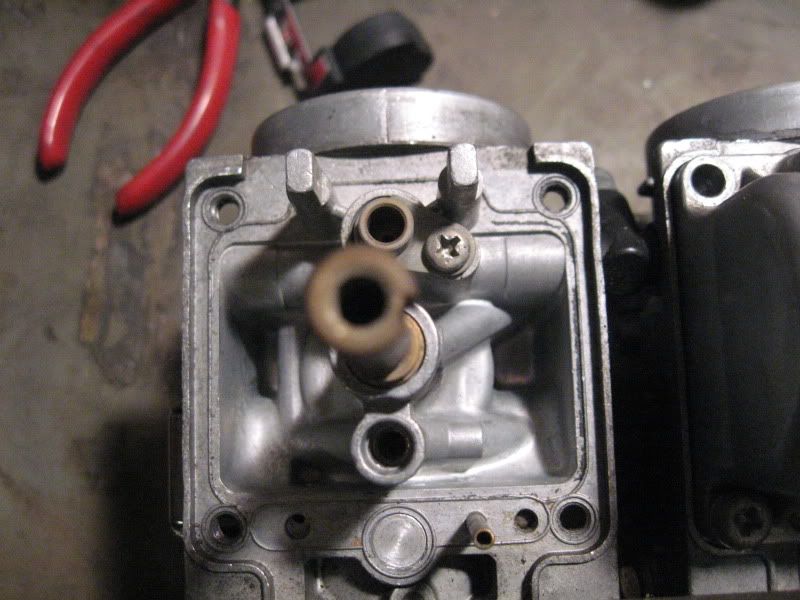

Ok, several things going on here; the large 'screw' is the main jet. Unscrew it and remember to take its copper/brass washer with it. Above it is the float valve seat. To remove this, take out the screw and the 'Y' clamp that hold it in, then gently grip it with some pliers (if you intend to reuse it) and twist and pull until it's out. There's a o-ring seal on this, replace this if it's more than a year or so old; this is another known leak problem (on the late carbs) as these dry out/shrink. The early carbs will have a hex-head on the seat and are threaded in; simply put the right size socket on it and unscrew it. Both seats will have a small dome-shaped filter on them, don't lose these. If you find much 'stuff' under these, I'd recommend breaking the rack to remove the fuel 'tees' so you can thoroughly clean these passages out. Anything left in here can quickly cause even new valves to leak.

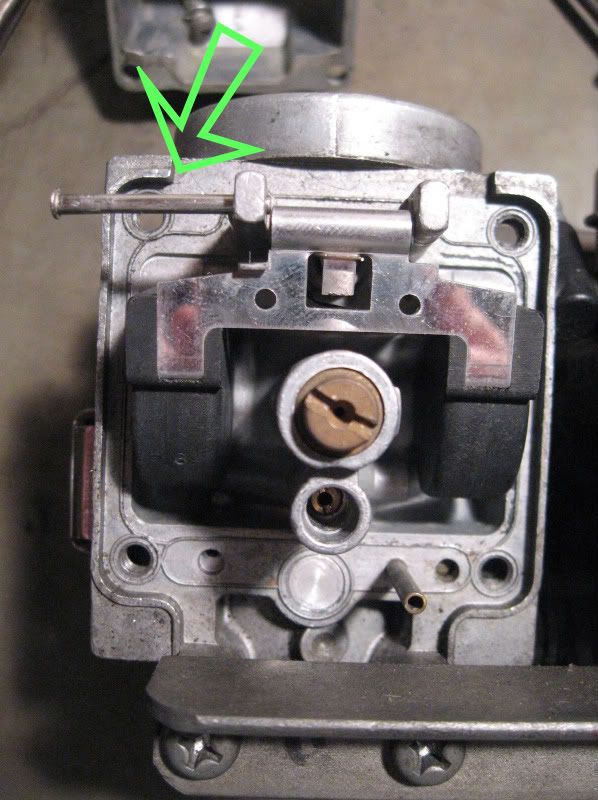

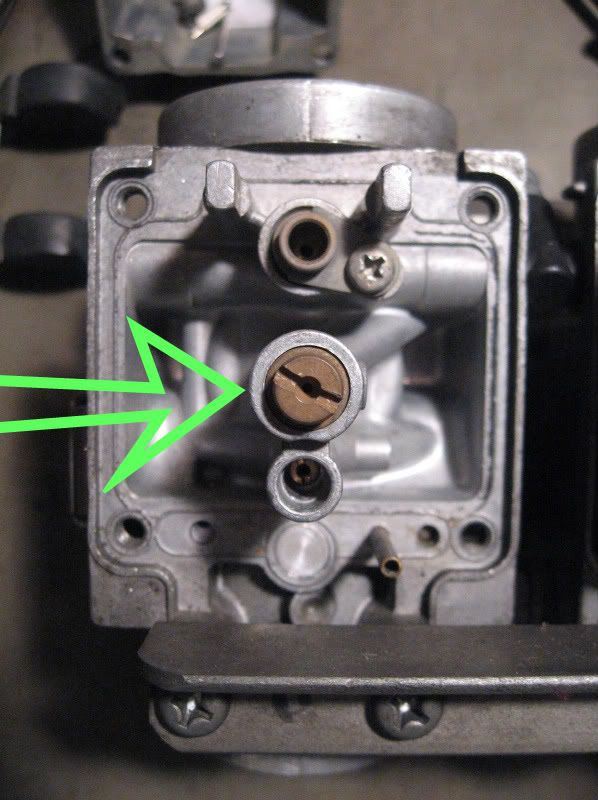

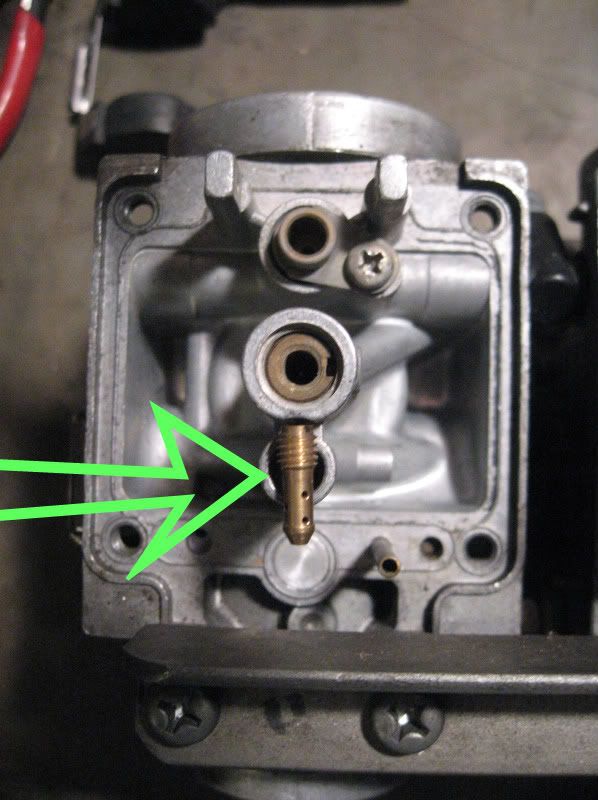

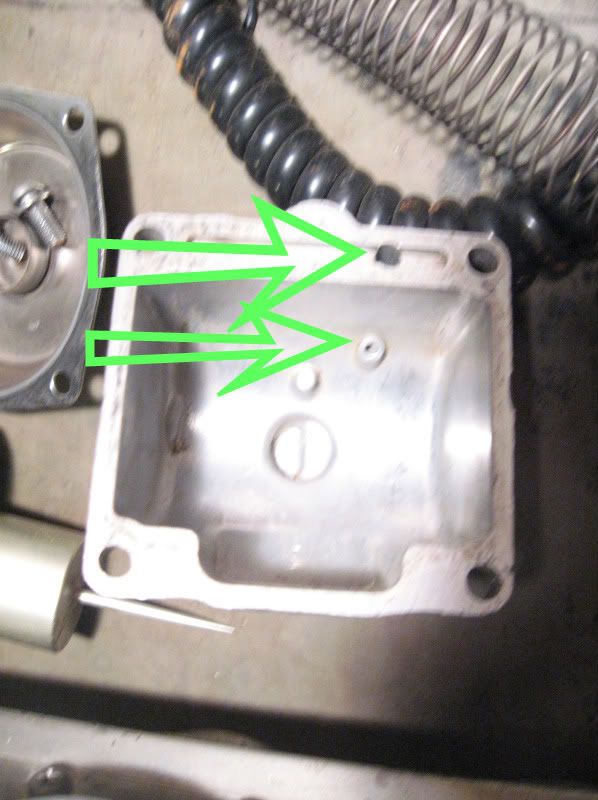

Directly below the now-removed main jet is the pilot jet. On most late carbs, this will be 'open' as seen here. Some '80 carbs may have a rubber plug covering this, if you found the remains of one or it doesn't fit tightly in the hole, you'll need to replace it (for more info on this recheck the linked guide). The '78-79 carbs will have a screw with a thin washer covering this passage, remove the screw.

The standard pilot jets are usually size 42.5. NOTE: The pilot jets are brass/copper and the screwdriver slots on top of them strip out easily and then it's hell to get them out. I had to drill one out. So make sure your screwdriver is sharp and fits tightly when you put it in the jet, and put pressure on it and turn slowly. It helps to soak the jets in penetrating oil before you try and get them out. Especially if they haven't been out lately.

Part 2 to follow

Comment