Hi guys

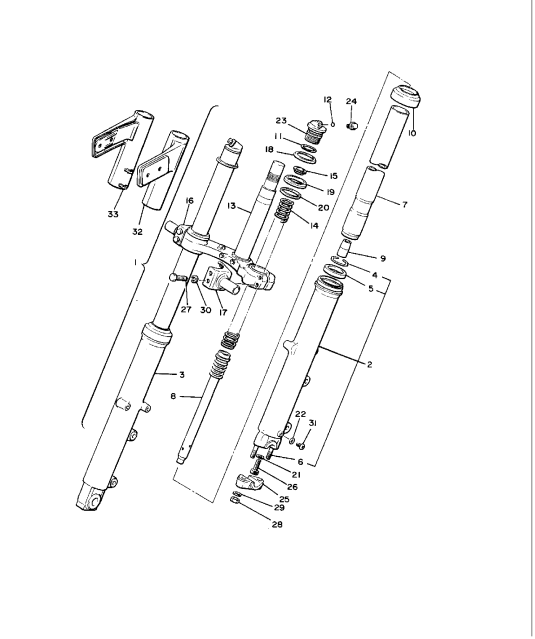

I'm trying to replace the seals on my front fork. The ones on the bike leaked when I bought it, and I thought it would make a nice winter project.

I have the forks off now, but I can't get the bottom bolt to thread out. It turns, so I assume the internal parts are slipping and preventing the bolt from threading out. Any suggestions on how I can get that bolt out?

Thanks

I'm trying to replace the seals on my front fork. The ones on the bike leaked when I bought it, and I thought it would make a nice winter project.

I have the forks off now, but I can't get the bottom bolt to thread out. It turns, so I assume the internal parts are slipping and preventing the bolt from threading out. Any suggestions on how I can get that bolt out?

Thanks

Oh well, live and learn.

Oh well, live and learn.

At some later time, somebody decided to do the seals and they got rid of the upper and lower guides. They weren't really doing anything anyway, right?

At some later time, somebody decided to do the seals and they got rid of the upper and lower guides. They weren't really doing anything anyway, right?

Comment