Well, while tearing into my girlfriend Karla's XJ1100, I've determined I need some advice.

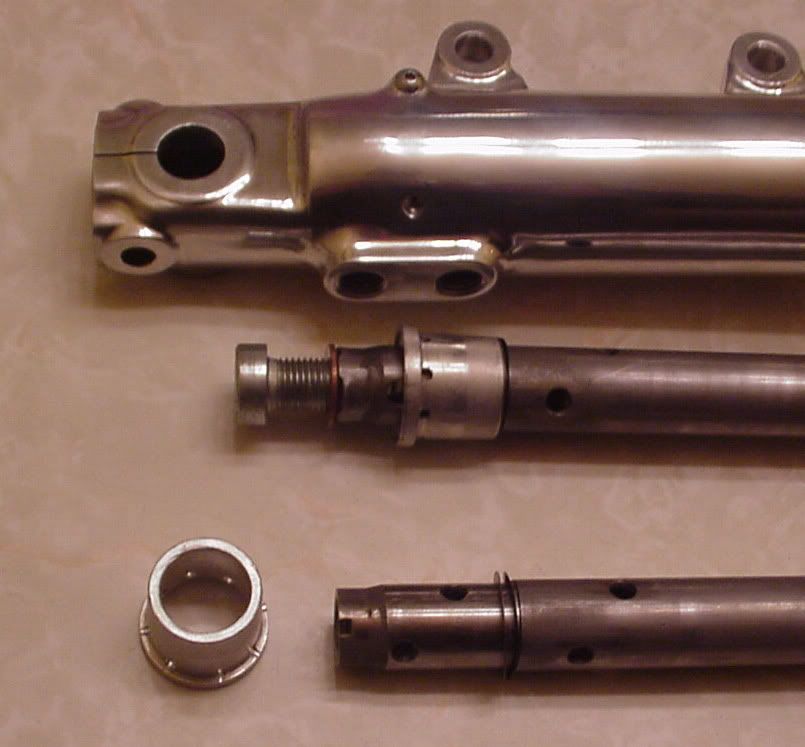

We were working on the front end, as the fork seals leak. Got the right side off and the fork apart. New seal in, everything back together, the bottom bolt on the fork leaks which means we tore up some of the threads inside the fork. Probably when trying to wrench that dang thing off. Yes, I did use locktight. What do you think is the best way to fix this? Tap and go with larger bolt?

Switch to the left side. Get the fork off the bike and no matter what we do we cant get the bottom bolt out. It's aaaalmost stripped now. We tried all sorts of methods, including heat. I stopped before we stripped it completely. So, suggestions on what to do with this one now?

Money is very very tight on this project, so going out and getting another set of forks is not an option. Want to just fix this set.

Any suggestions welcomed!

And yes, there were a lot of choice words throughout this process.......

We were working on the front end, as the fork seals leak. Got the right side off and the fork apart. New seal in, everything back together, the bottom bolt on the fork leaks which means we tore up some of the threads inside the fork. Probably when trying to wrench that dang thing off. Yes, I did use locktight. What do you think is the best way to fix this? Tap and go with larger bolt?

Switch to the left side. Get the fork off the bike and no matter what we do we cant get the bottom bolt out. It's aaaalmost stripped now. We tried all sorts of methods, including heat. I stopped before we stripped it completely. So, suggestions on what to do with this one now?

Money is very very tight on this project, so going out and getting another set of forks is not an option. Want to just fix this set.

Any suggestions welcomed!

And yes, there were a lot of choice words throughout this process.......

I don't remember breaking anything though.

I don't remember breaking anything though.

[/IMG]

[/IMG]

Comment