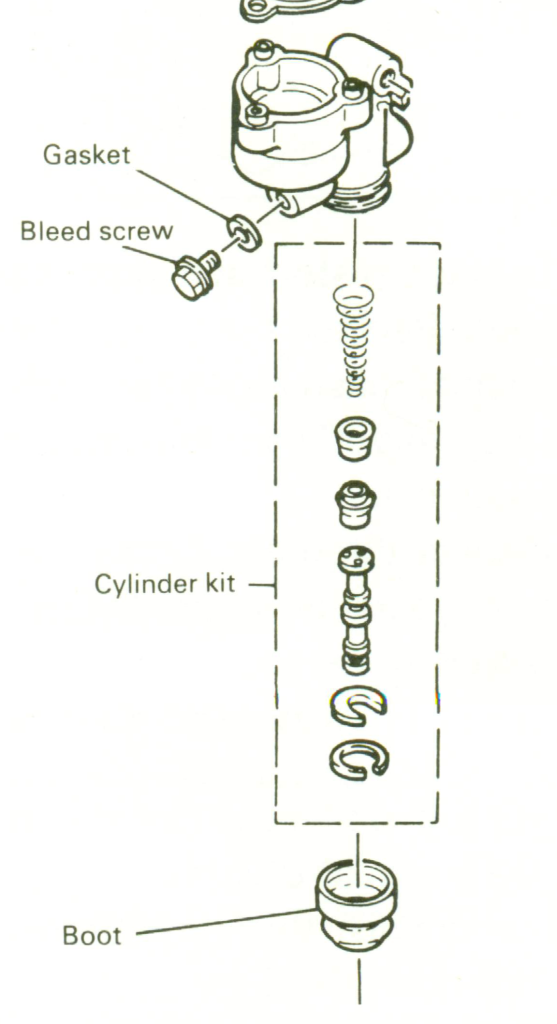

I am in the process of rebuilding the rear brakes on an 81 xs1100s. After rebuilding the rear master cylinder I can't seem to get the fluid past the rubber cups down to the wheel cylinder. I can feel air pressure so I know the master is pumping. Is there a procedure to get the fluid past the cup into the lines?

Comment