Got a lot of requests to post this. Not sure if this is correct location but I'm sure TC will move if it isn't.

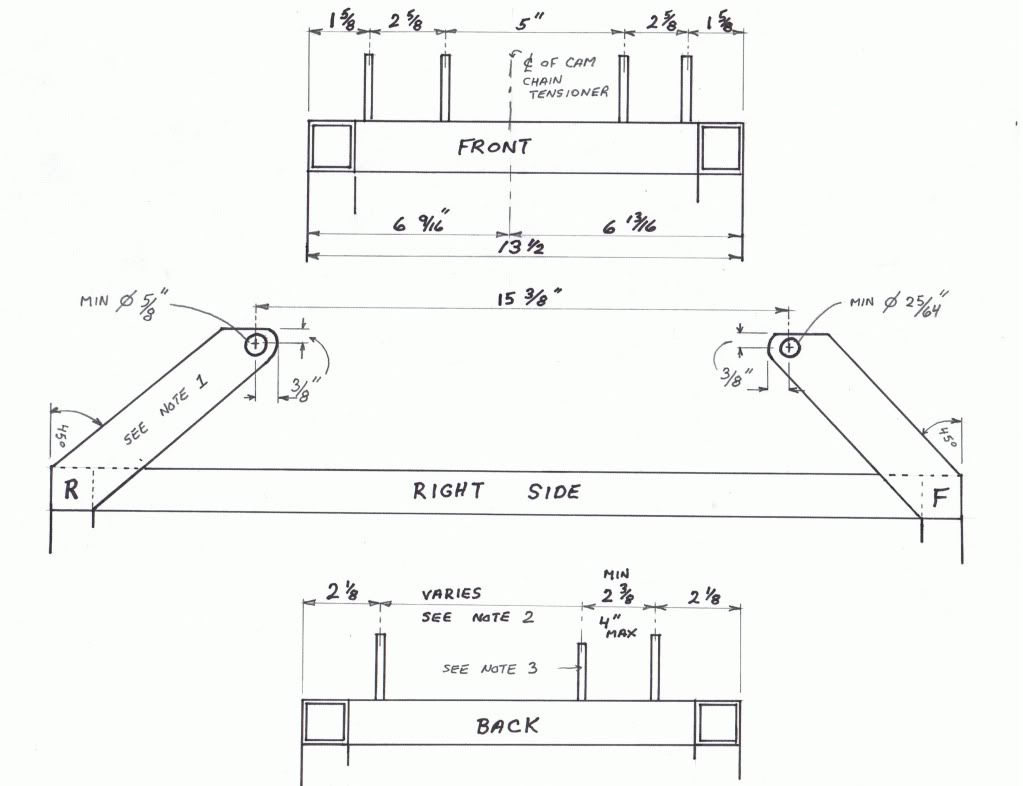

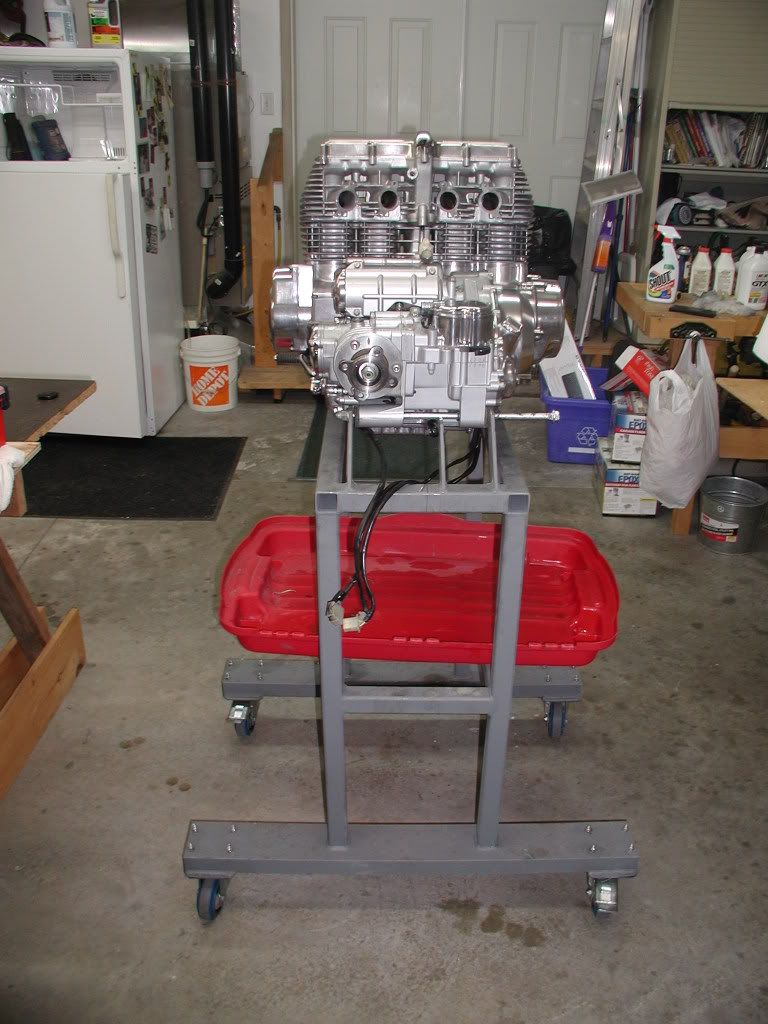

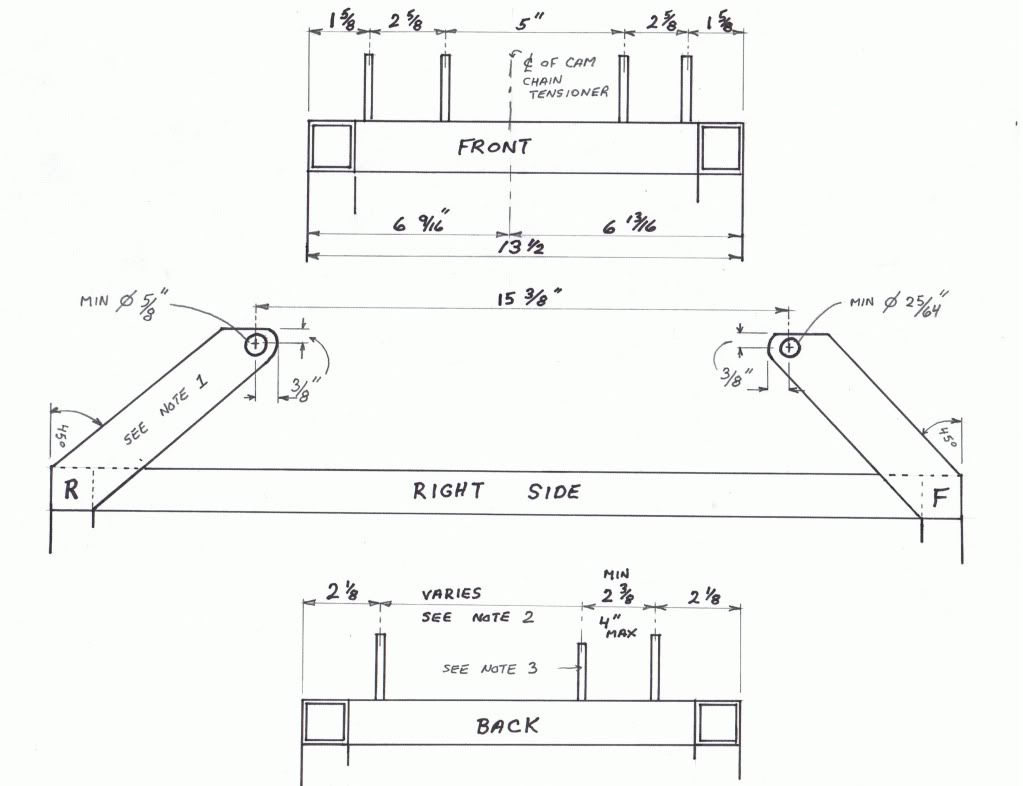

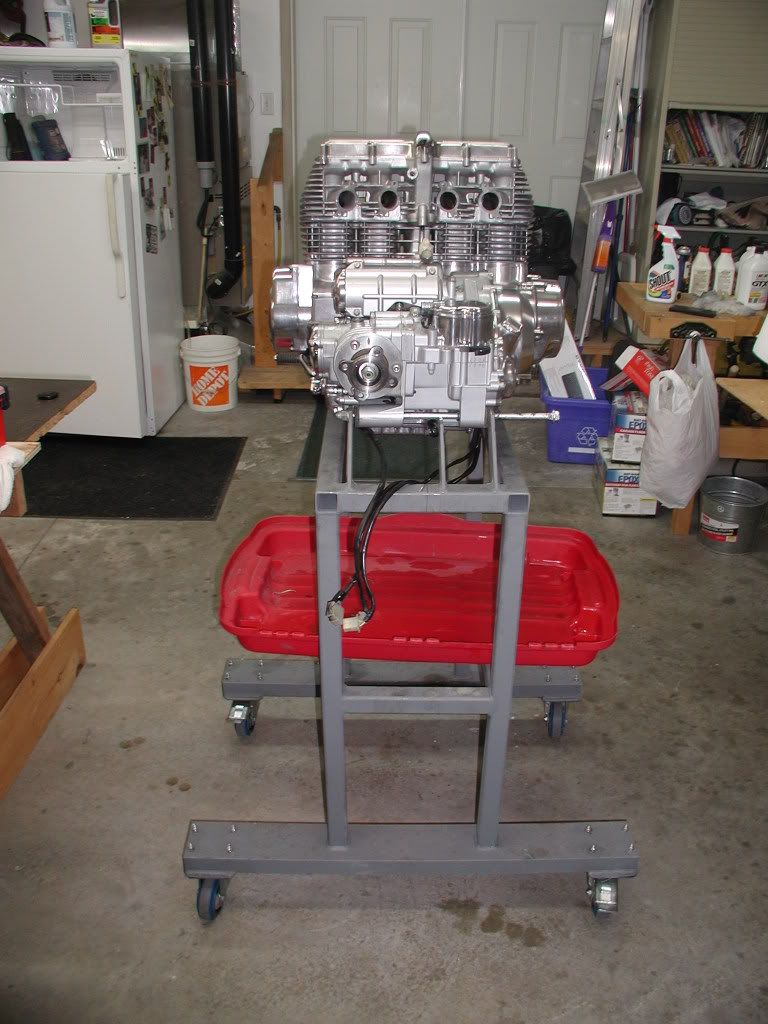

General: This stand was made from 3/16 x 1 1/4 inch tubular steel, with the motor mounts made from 3/16 flat steel. The base is channel with flat steel welded to bottom on the corners to accomodate the 4 inch wheels. Two of the wheels are locking and are located on opposite corners. I have a rotten back so my stand is tall. The frame height is 37 3/4, with 4 inch wheels making the overall height from the floor to the top of the valve cover about 59 inches. Also the channel extends past the frame 12 inches for lateral stability. You can launch a rocket off this thing. The actual frame on mine measures 13 1/2 x 25 1/4 but the 25 1/4 could change if you use longer flat steel for motor mounts.

Next thing you'll notice once you have your motor out is that it isn't symetrical. I used the centre line of the cam chain tensioner hole as my starting point.

Note #1 : the motor mounts at the back of my unit are 5 1/2 inches long from the out side of the frame, the ones at the front are 4 inches. I did this so that the engine tips slightly forward so the engine oil will drain completely. As I said above these can be longer to have the base of the pan sitting farther above the top of the frame.

Note #2 The center motor mount at the rear can be moved from the 2 3/8 position up to a maximum of 4 inches. Anything wider than that will obstruct the middle gear drain plug.

Note #3, The rear middle motor mount really doesn't need a full hole. Once I drilled the holes I cut the top half of this one off. It provides no lateral stability but is there only to support the center of the long thru bolt that passes through the entire width of the rear mounts.

Mine also has intermediate bracing around the mid height position. Really not needed but I use it to place a plastic tote lid in. It's good for placing the oil drain pan in as well as catching nuts and bolts etc. before they hit the floor and vanish.

This next one is a shot of the wheel base

Last thing to mention are the bracket holes. The fronts are a different size than the back ones. I'd imagine it has something to do with four mounts at the front when it's in the frame.

I know someone will ask what this costs to make. The wheels were the most expensive part. Your costs will vary.

Good luck

Mack

General: This stand was made from 3/16 x 1 1/4 inch tubular steel, with the motor mounts made from 3/16 flat steel. The base is channel with flat steel welded to bottom on the corners to accomodate the 4 inch wheels. Two of the wheels are locking and are located on opposite corners. I have a rotten back so my stand is tall. The frame height is 37 3/4, with 4 inch wheels making the overall height from the floor to the top of the valve cover about 59 inches. Also the channel extends past the frame 12 inches for lateral stability. You can launch a rocket off this thing. The actual frame on mine measures 13 1/2 x 25 1/4 but the 25 1/4 could change if you use longer flat steel for motor mounts.

Next thing you'll notice once you have your motor out is that it isn't symetrical. I used the centre line of the cam chain tensioner hole as my starting point.

Note #1 : the motor mounts at the back of my unit are 5 1/2 inches long from the out side of the frame, the ones at the front are 4 inches. I did this so that the engine tips slightly forward so the engine oil will drain completely. As I said above these can be longer to have the base of the pan sitting farther above the top of the frame.

Note #2 The center motor mount at the rear can be moved from the 2 3/8 position up to a maximum of 4 inches. Anything wider than that will obstruct the middle gear drain plug.

Note #3, The rear middle motor mount really doesn't need a full hole. Once I drilled the holes I cut the top half of this one off. It provides no lateral stability but is there only to support the center of the long thru bolt that passes through the entire width of the rear mounts.

Mine also has intermediate bracing around the mid height position. Really not needed but I use it to place a plastic tote lid in. It's good for placing the oil drain pan in as well as catching nuts and bolts etc. before they hit the floor and vanish.

This next one is a shot of the wheel base

Last thing to mention are the bracket holes. The fronts are a different size than the back ones. I'd imagine it has something to do with four mounts at the front when it's in the frame.

I know someone will ask what this costs to make. The wheels were the most expensive part. Your costs will vary.

Good luck

Mack

Comment