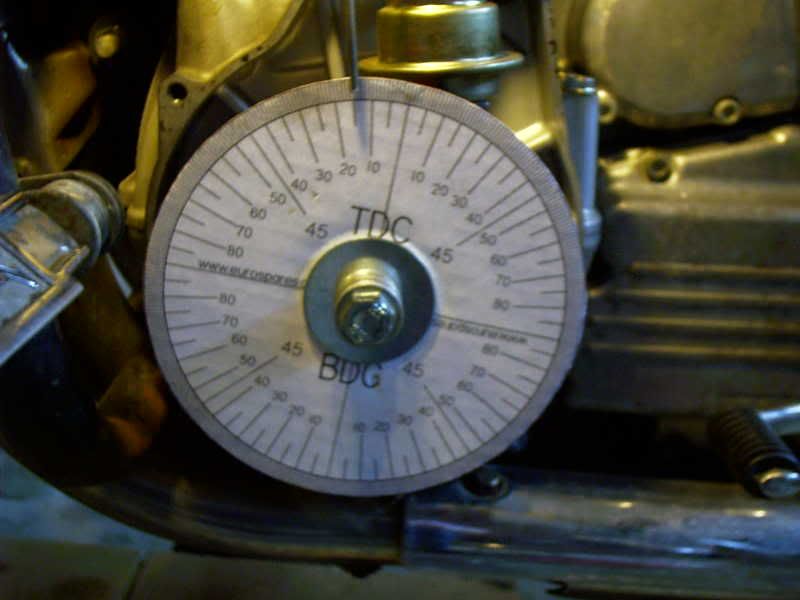

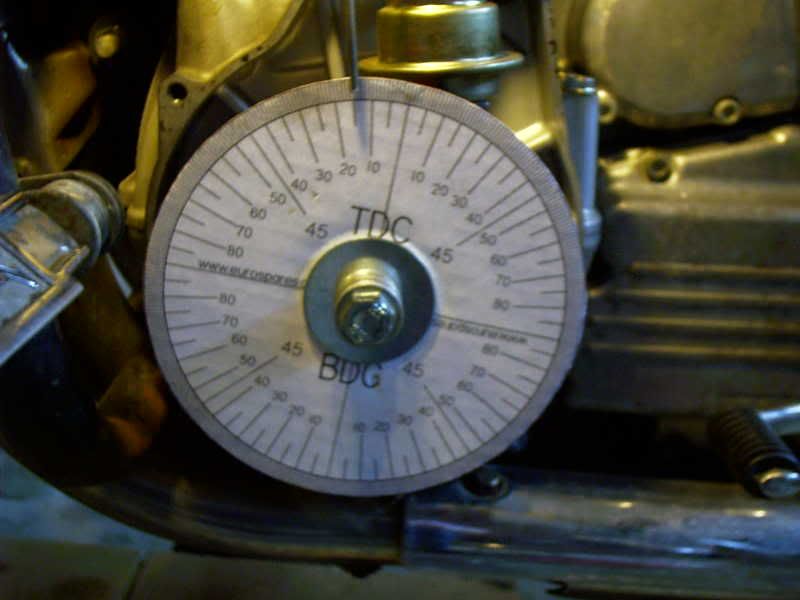

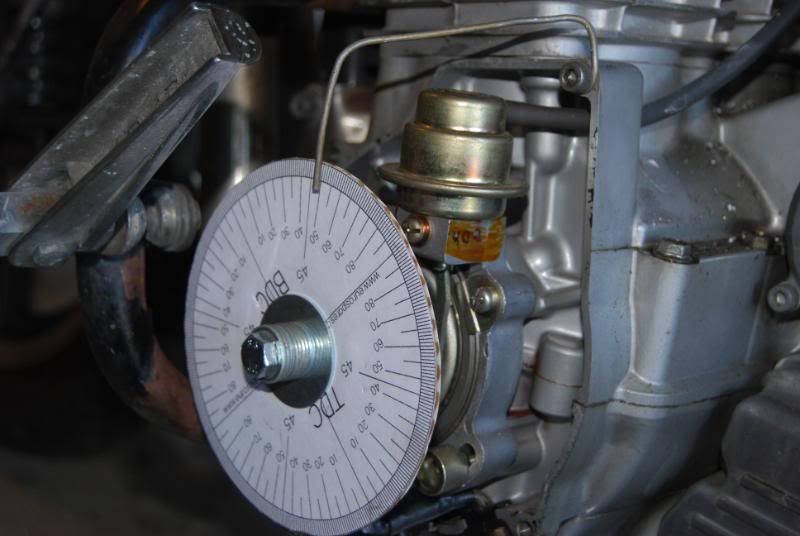

A degree wheel is one of those tools you rarely need, but when you need it, you need it. Today I needed one, and not being one to drop $50 on a little metal disc I may not use again for a long time I got creative. I found an image of a degree wheel, printed it on paper, and rubber cemented it to a piece of cardboard. The cool thing about doing it this way is you can make the wheel virtually any size you want. On the bike I was working on I couldn't use a 7" wheel as the engine guards were in the way. I just sized it down when printing, and made one the perfect size for the application. I bolted it to the motor over the top of the timing plate with some washers to take up the slack, and I bolted a piece of coat hanger to the motor, and used that for my pointer. Total expenditure was $2 for a bottle of rubber cement. Here's a link to the degree wheel graphic, and here's a pic of the installed wheel -

.

.

Comment