Hey there folks,

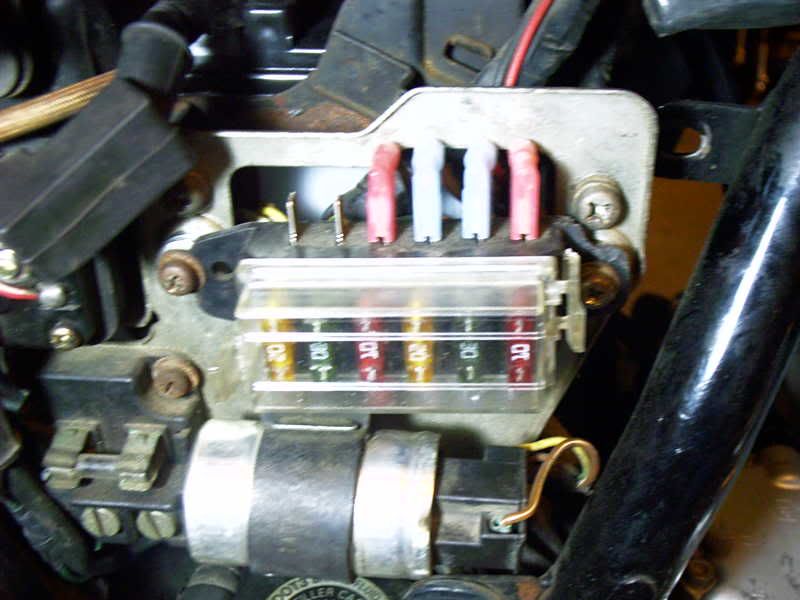

I was recently contacted by a fellow XSive that got one of the new fuseblocks with the insulated 90 degree connectors set. But he's having trouble crimping the connector onto the wires without destroying/mangling up the connector? I just tried it myself, and that plastic insulation is guerilla tough!! My el cheapo wire crimper tool with 3 crimping sizes would not give me enough leverage to adequately crimp the wire SNUGLY into the connector!

I just tried it myself, and that plastic insulation is guerilla tough!! My el cheapo wire crimper tool with 3 crimping sizes would not give me enough leverage to adequately crimp the wire SNUGLY into the connector!  I tried trimming off the insulation to reveal the bare metal, but it still didn't seem to work right!? :Confused:

I tried trimming off the insulation to reveal the bare metal, but it still didn't seem to work right!? :Confused:

I've seen several examples of folks who have gotten and used these new connectors, what is trick in getting them properly crimped? Did you use some large channel locks instead!?

If these connectors are too difficult to work with, then I might NOT provide them afterall, but would like to see/hear some feedback on how folks installed them! Thanks for both me and the "other" xsive...kept anonymous.

T.C.

I was recently contacted by a fellow XSive that got one of the new fuseblocks with the insulated 90 degree connectors set. But he's having trouble crimping the connector onto the wires without destroying/mangling up the connector?

I just tried it myself, and that plastic insulation is guerilla tough!! My el cheapo wire crimper tool with 3 crimping sizes would not give me enough leverage to adequately crimp the wire SNUGLY into the connector!

I just tried it myself, and that plastic insulation is guerilla tough!! My el cheapo wire crimper tool with 3 crimping sizes would not give me enough leverage to adequately crimp the wire SNUGLY into the connector!  I tried trimming off the insulation to reveal the bare metal, but it still didn't seem to work right!? :Confused:

I tried trimming off the insulation to reveal the bare metal, but it still didn't seem to work right!? :Confused: I've seen several examples of folks who have gotten and used these new connectors, what is trick in getting them properly crimped? Did you use some large channel locks instead!?

If these connectors are too difficult to work with, then I might NOT provide them afterall, but would like to see/hear some feedback on how folks installed them! Thanks for both me and the "other" xsive...kept anonymous.

T.C.

that i bought years ago when i became an electrician.good luck with your fuse blocks....Thanks again T.C for the fuse block they work so good

that i bought years ago when i became an electrician.good luck with your fuse blocks....Thanks again T.C for the fuse block they work so good

Comment