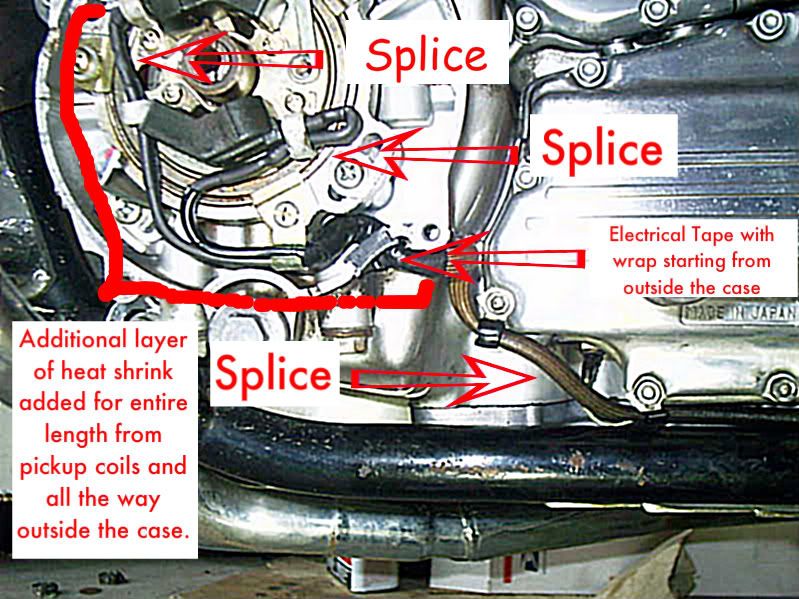

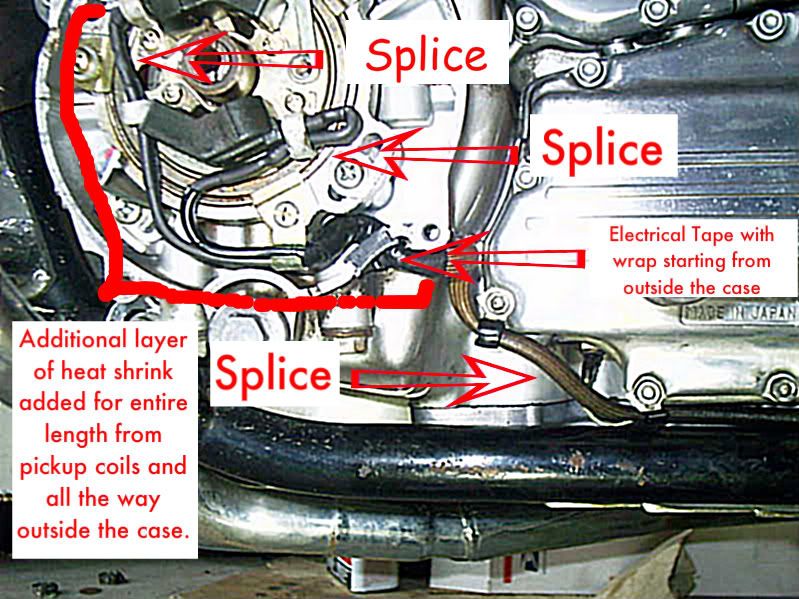

So I just finished tracking down an intermittent problem with my pickup coil wires. They had been fixed at least twice before, and it was a real PITA trying to diagnose the problem. When I fixed the wires, I did it so I won't have to do it again. I took the pickup coil assembly completely out, marked the location of the wires and cut them all. Then with the piece in front of me where I could really work on it well, I unsoldered the short connections to the pickup coils and resoldered long test lead wires in four different colors. Then I put a long piece (3" or so) of heat shrink over the connections. Then I took a larger piece of heat shrink and encased both wires for each pickup coil all the way outside the case. I peeled the fabric sheathing back from the wires under the transmission case and secured it with a twist tie to hold it in place. Then I cut the wires before the original yamaha splice, slid some more heat shrink onto the wires, grafted in my new wires cut to the appropriate length, and applied heat shrink. Then I pulled the fabric sheathing back up over the wires, and wrapped it with electrical tape starting on the outside and working in.

The thing I like about this setup is that I don't have four thin wires bending all over the place under the timing cover - I've got two with very heavy insulation over them. This should provide protection should they ever get up against the timing wheel or rub internally. My solder connections are all immobilized with the clips, so the only thing that moves is the test lead wires. Even that has such thick insulation on it that it won't allow the wires to make sharp bends which could break the wires internally. Besides, it just looks pretty. Here's a pic -

The thing I like about this setup is that I don't have four thin wires bending all over the place under the timing cover - I've got two with very heavy insulation over them. This should provide protection should they ever get up against the timing wheel or rub internally. My solder connections are all immobilized with the clips, so the only thing that moves is the test lead wires. Even that has such thick insulation on it that it won't allow the wires to make sharp bends which could break the wires internally. Besides, it just looks pretty. Here's a pic -

.

. .

.

Comment