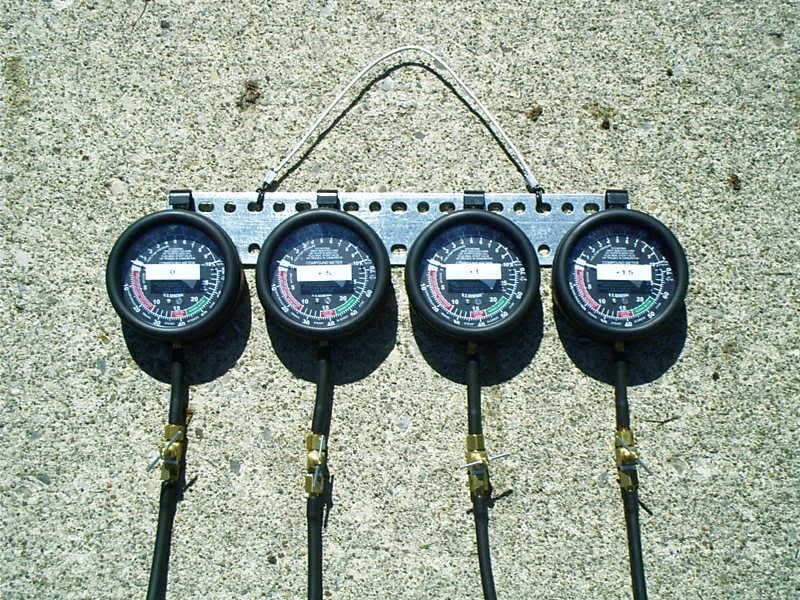

I built my own set of synch gauges, and like many others I put them all on the same cylinder at the same rpm to calibrate them. I found them all to be a little off using this method, so I labeled them and used that calibration for synchronizing carbs. DGXSER was over last week, and said that he had calibrated his gauge using a vacuum bleeder pump that also had a gauge. That got me to thinking (talk about being on foreign ground  ) so this morning I went over to Harbor Freight and bought a vacuum bleeder. I didn't get the Harbor Freight brand - I bit the bullet and got a genuine Mity Vac cause I wanted as much accuracy as I could get - besides they were out of the house brand

) so this morning I went over to Harbor Freight and bought a vacuum bleeder. I didn't get the Harbor Freight brand - I bit the bullet and got a genuine Mity Vac cause I wanted as much accuracy as I could get - besides they were out of the house brand  . I put it on my synch gauges, and what do you know - they all read dead even. I put the synch gauges on Betsy and adjusted her synch, and it made a difference. I was already pretty close, but not dead on it. Now I am, and it leaves me with this conclusion about using the vacuum from the motor to calibrate your gauges - it's not a terribly accurate way to do it. It'll let you know if they're way off, but I just don't think the tach is accurate enough to really calibrate them well. Just passing it along.

. I put it on my synch gauges, and what do you know - they all read dead even. I put the synch gauges on Betsy and adjusted her synch, and it made a difference. I was already pretty close, but not dead on it. Now I am, and it leaves me with this conclusion about using the vacuum from the motor to calibrate your gauges - it's not a terribly accurate way to do it. It'll let you know if they're way off, but I just don't think the tach is accurate enough to really calibrate them well. Just passing it along.

) so this morning I went over to Harbor Freight and bought a vacuum bleeder. I didn't get the Harbor Freight brand - I bit the bullet and got a genuine Mity Vac cause I wanted as much accuracy as I could get - besides they were out of the house brand

) so this morning I went over to Harbor Freight and bought a vacuum bleeder. I didn't get the Harbor Freight brand - I bit the bullet and got a genuine Mity Vac cause I wanted as much accuracy as I could get - besides they were out of the house brand  . I put it on my synch gauges, and what do you know - they all read dead even. I put the synch gauges on Betsy and adjusted her synch, and it made a difference. I was already pretty close, but not dead on it. Now I am, and it leaves me with this conclusion about using the vacuum from the motor to calibrate your gauges - it's not a terribly accurate way to do it. It'll let you know if they're way off, but I just don't think the tach is accurate enough to really calibrate them well. Just passing it along.

. I put it on my synch gauges, and what do you know - they all read dead even. I put the synch gauges on Betsy and adjusted her synch, and it made a difference. I was already pretty close, but not dead on it. Now I am, and it leaves me with this conclusion about using the vacuum from the motor to calibrate your gauges - it's not a terribly accurate way to do it. It'll let you know if they're way off, but I just don't think the tach is accurate enough to really calibrate them well. Just passing it along.

Comment