Port Surfaces

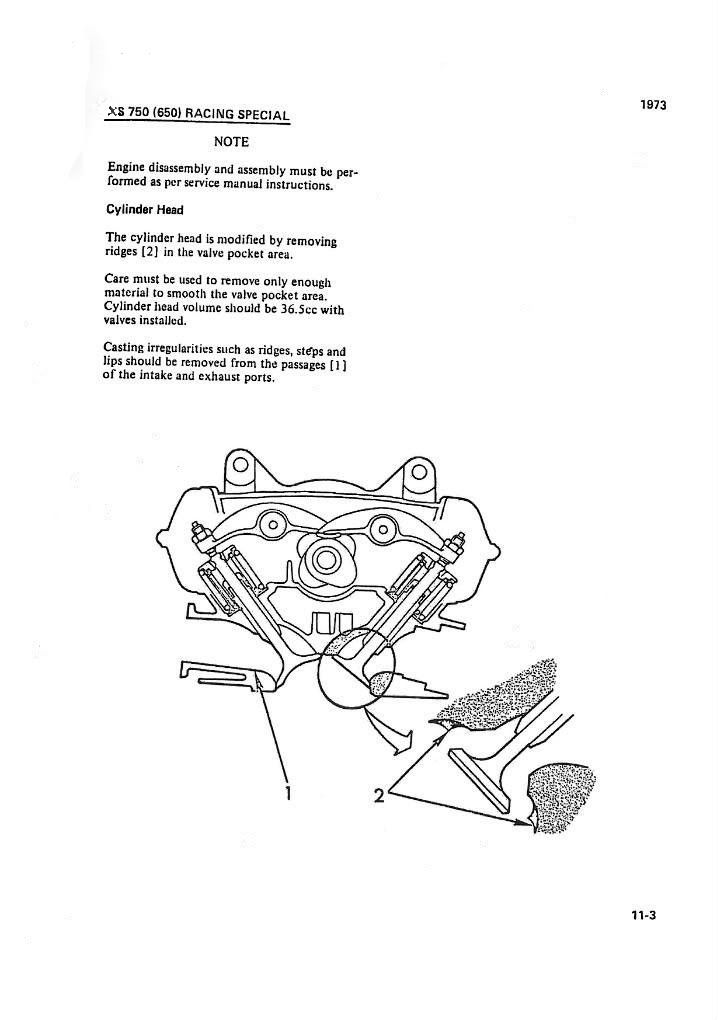

The intake ports see wet flow and the exhaust see dry and so the intake ports should have a finish that is course, something on the order of 400 grit and the exhaust should be as slick as possible. The most important part of the port is the bowl just below the valve and the short side radius. The intake port measures about 1.35 inches at the opening and the intake valve on the late head measures 1.5 inches and the port should be funnel shaped and the guide which is huge in stock form blended and shaped favoring the entry and floor of the port and the two left ports enter the chamber differently than the two right ports. The shape is the most important and the port can easily be ruined if it's not correct and it's velocity that you are after not maximum size and flow. The port volume should be based on the displacement of the cylinder and the rpm in which the motor will be working which is not unlike camshaft timing in that the bigger the motor the bigger the port volume needs to be. The age old mod of blending the intake boot to the head (port matching) and removing the casting flash with a porting tool (400 grit tootsie roll) is all the novice porter should attempt. The chambers are slick enough to begin with and should be left alone because it's easy to take a couple cc's out of them and a couple cc's just lost you a half point of compression. A fine stainless steel rotary wire brush turned at slow speed will slick them up without removing any material. Mention is made that the late head in stock form will flow about 10% more than a stock early head and because of the larger valve in the late head the funnel shape can be more pronounced than that of the early head because the size of the entry is the same for both. The late head is much better in stock form from about .200 valve lift up than the early one and in modified form the disparity is even greater. The early head is fine for a heavy touring bike but if it's top end horsepower you are after it's not the plan. The ultimate torquer using stock parts for a Wing Ding type XS would be the early head, late pistons and late cams. If you were building a race head and using custom pistons you would do major work on the chambers but if you are using stock pistons or off the shelf Wiseco's you are fighting for compression and so leave the chambers alone. You can cut the head .016 without having to worry about cam chain problems or having to advance the cams and pick up .38 of a point of compression. You can paint the piston domes with VHT Hi Temp header paint and cook them in an oven at 300 degrees for one hour which cures and hardens the paint so it won't come off but all this really does is speed up the carbon build up on the piston dome, ditto for glass beading the piston tops and I've tried all this stuff on race car motors on the dyno and found nothing power wise. Wiseco, Venolia, J&E and others offer coating services for some of their pistons but any of this skirt coating stuff is tricky business and can do more harm than good if not applied properly. The latest generation of Wiseco pistons for our XS bikes are plenty trick and all they need is a properly finished bore to work and I might add that a properly finished bore cannot be obtained with a hand held hone especially a dry hone. My cylinders were bored and honed by Advanced Sleeves in Mentor Ohio on a Sunnen CK-10 machine and they came out perfect. See picture,

Damn, I forgot what the original question was, I must be getting old.

The intake ports see wet flow and the exhaust see dry and so the intake ports should have a finish that is course, something on the order of 400 grit and the exhaust should be as slick as possible. The most important part of the port is the bowl just below the valve and the short side radius. The intake port measures about 1.35 inches at the opening and the intake valve on the late head measures 1.5 inches and the port should be funnel shaped and the guide which is huge in stock form blended and shaped favoring the entry and floor of the port and the two left ports enter the chamber differently than the two right ports. The shape is the most important and the port can easily be ruined if it's not correct and it's velocity that you are after not maximum size and flow. The port volume should be based on the displacement of the cylinder and the rpm in which the motor will be working which is not unlike camshaft timing in that the bigger the motor the bigger the port volume needs to be. The age old mod of blending the intake boot to the head (port matching) and removing the casting flash with a porting tool (400 grit tootsie roll) is all the novice porter should attempt. The chambers are slick enough to begin with and should be left alone because it's easy to take a couple cc's out of them and a couple cc's just lost you a half point of compression. A fine stainless steel rotary wire brush turned at slow speed will slick them up without removing any material. Mention is made that the late head in stock form will flow about 10% more than a stock early head and because of the larger valve in the late head the funnel shape can be more pronounced than that of the early head because the size of the entry is the same for both. The late head is much better in stock form from about .200 valve lift up than the early one and in modified form the disparity is even greater. The early head is fine for a heavy touring bike but if it's top end horsepower you are after it's not the plan. The ultimate torquer using stock parts for a Wing Ding type XS would be the early head, late pistons and late cams. If you were building a race head and using custom pistons you would do major work on the chambers but if you are using stock pistons or off the shelf Wiseco's you are fighting for compression and so leave the chambers alone. You can cut the head .016 without having to worry about cam chain problems or having to advance the cams and pick up .38 of a point of compression. You can paint the piston domes with VHT Hi Temp header paint and cook them in an oven at 300 degrees for one hour which cures and hardens the paint so it won't come off but all this really does is speed up the carbon build up on the piston dome, ditto for glass beading the piston tops and I've tried all this stuff on race car motors on the dyno and found nothing power wise. Wiseco, Venolia, J&E and others offer coating services for some of their pistons but any of this skirt coating stuff is tricky business and can do more harm than good if not applied properly. The latest generation of Wiseco pistons for our XS bikes are plenty trick and all they need is a properly finished bore to work and I might add that a properly finished bore cannot be obtained with a hand held hone especially a dry hone. My cylinders were bored and honed by Advanced Sleeves in Mentor Ohio on a Sunnen CK-10 machine and they came out perfect. See picture,

Damn, I forgot what the original question was, I must be getting old.

Comment