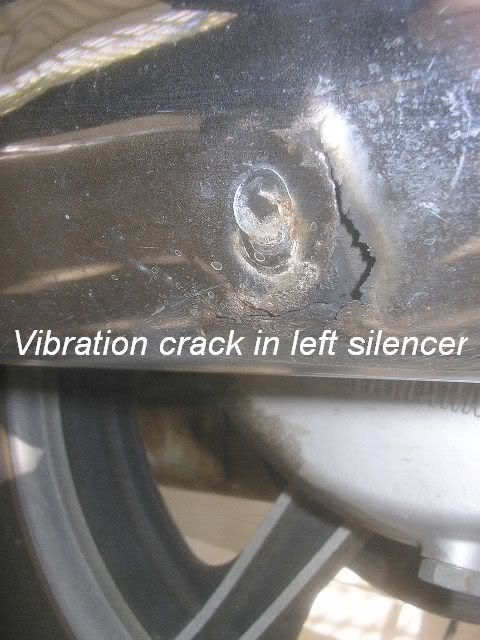

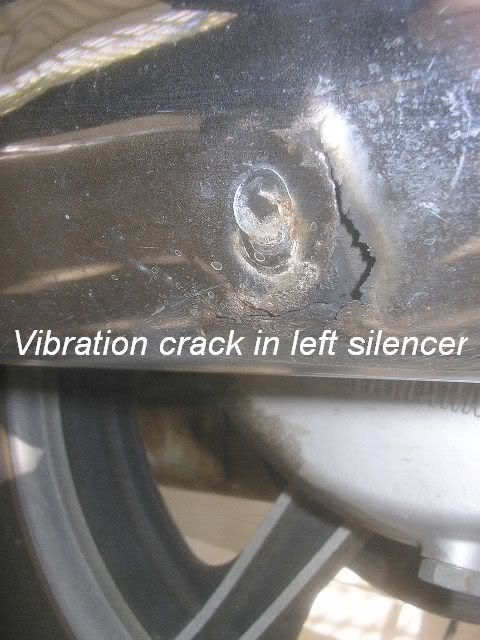

XSives- see pic

Can this vibration crack in the left silencer material be repaired? As one can see its very thin in this oem welded area. Because of it's low position the crack is not visible to the casual eye. I've heard stainless wire can be used to mig-weld plated steel- is this true? Anyone out there with experience in this type of repair?

Rob

Can this vibration crack in the left silencer material be repaired? As one can see its very thin in this oem welded area. Because of it's low position the crack is not visible to the casual eye. I've heard stainless wire can be used to mig-weld plated steel- is this true? Anyone out there with experience in this type of repair?

Rob

Comment