Just a word of caution for anyone considering milling on their head. Just remember that as you mill the head, you're taking away meat from where the exhaust studs go into the head as well as on the intake where your carb boots screw in...

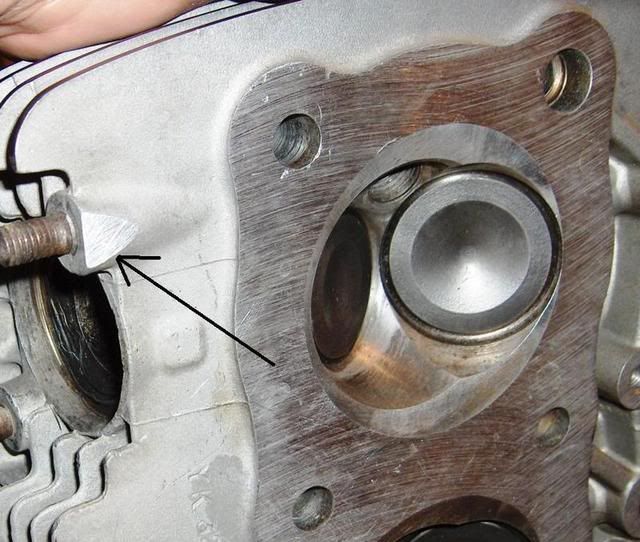

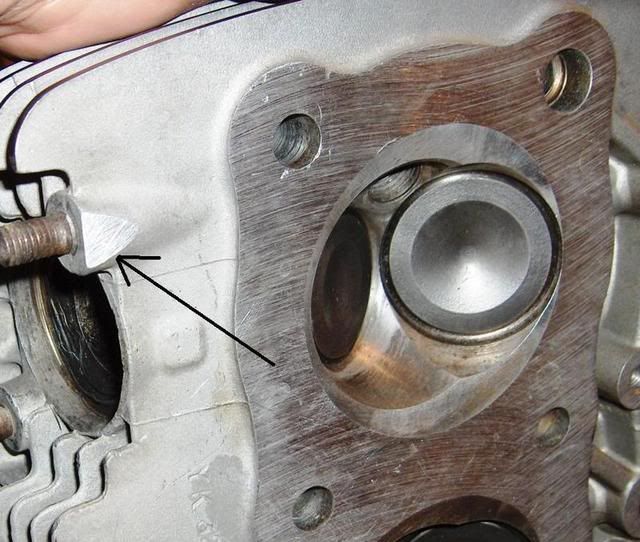

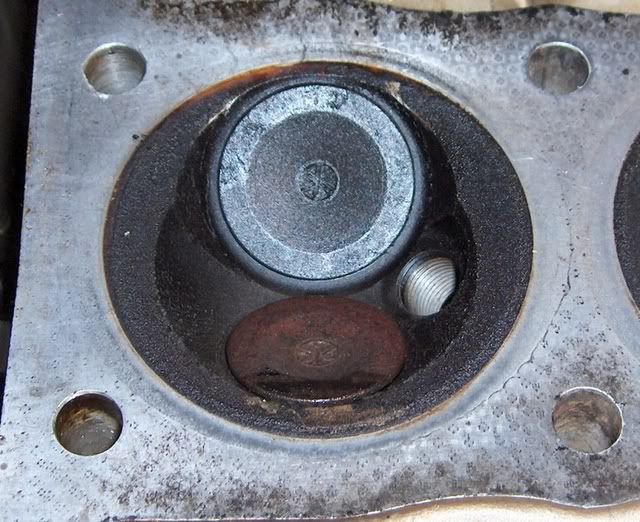

If you have the later model heads with the bigger valves like these, notice how close they are to the edge after milling.

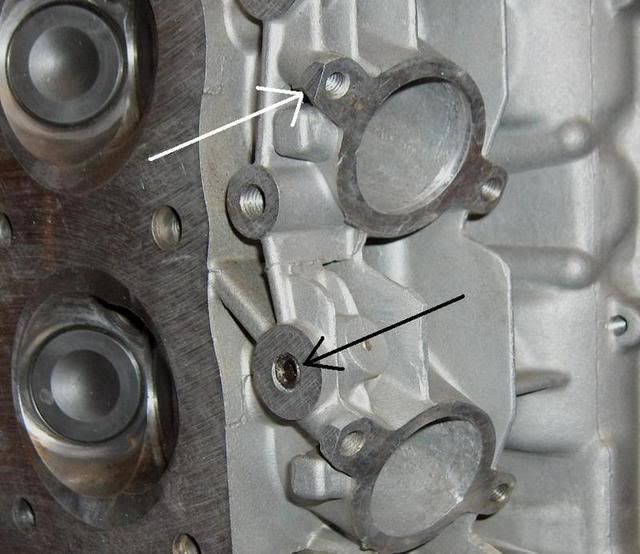

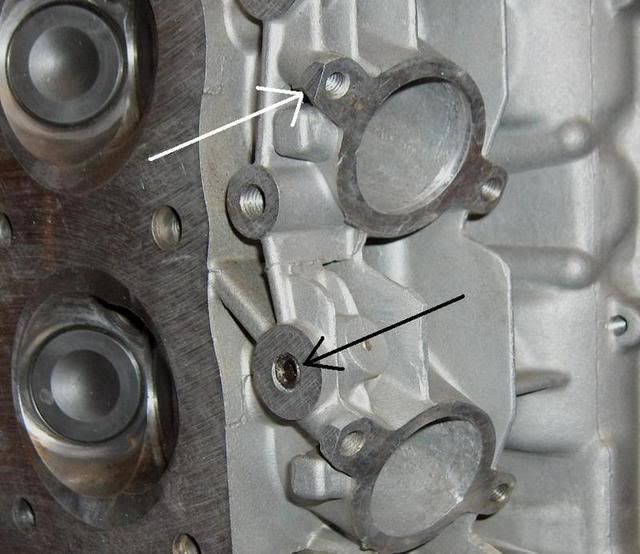

In the second photo you'll also see how I tapped and blocked off the YICS tubes (Black arrow). If for some reason I decided to ever go back to that system, those allen screws will come out.

I had quite a bit of work done to this head. Most of it was done in opening up the area immediately before the intake valves. The roughest of the casting was knocked down, but it was left rough. Nothing was done to the exhaust side except that both intake and exhaust valve seats were opened a bit to where the valve faces were hitting more towards the edges than in the middle of the face like the book calls for. I'm doing all this with the new 1179 bore, so if I make more power, I won't be exactly sure where it came from: The milled head, the porting, or just more CC's???

Tod

If you have the later model heads with the bigger valves like these, notice how close they are to the edge after milling.

In the second photo you'll also see how I tapped and blocked off the YICS tubes (Black arrow). If for some reason I decided to ever go back to that system, those allen screws will come out.

I had quite a bit of work done to this head. Most of it was done in opening up the area immediately before the intake valves. The roughest of the casting was knocked down, but it was left rough. Nothing was done to the exhaust side except that both intake and exhaust valve seats were opened a bit to where the valve faces were hitting more towards the edges than in the middle of the face like the book calls for. I'm doing all this with the new 1179 bore, so if I make more power, I won't be exactly sure where it came from: The milled head, the porting, or just more CC's???

Tod

Comment