Hey folks,

This is NO April's Fool thread. A couple of nights ago, was doing the laundry, and noticed that the dryer seemed to be running a long time. Checked the clothes....and they were still damp and COLD! Rechecked the settings, changed from SENSOR dry to Timed Dry, same thing, NO HEAT!

Rechecked the settings, changed from SENSOR dry to Timed Dry, same thing, NO HEAT!

Read up on it...a Maytag Commercial Grade dryer from some 16 years ago, found a parts/price listing....and figured the most common cause of loss of heat was a fried/broken heating element! Found one for about $85.00! But I also found some other repair links, learned about testing it with an OHMMETER first!

But I also found some other repair links, learned about testing it with an OHMMETER first!

Tonight after dinner, got into it, had to pull it out from it's upstairs hallway slot, disconnect the power and exhaust vent, then pulled the front off first.

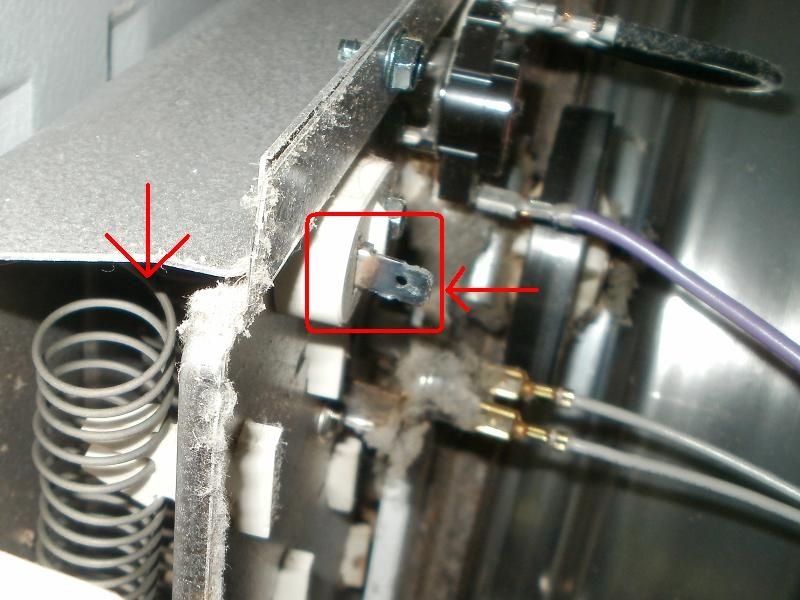

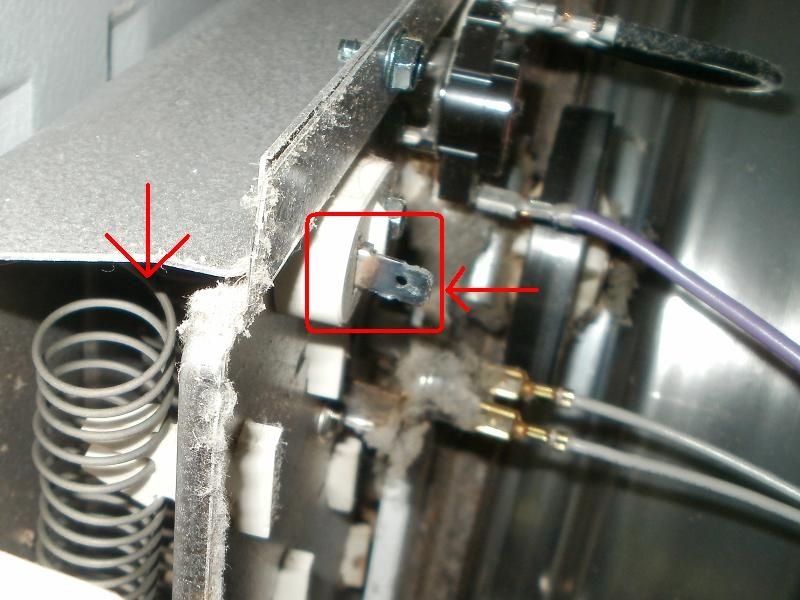

Then got down and looked up/back towards the heating element...and was a bit surprised to see this!

Pulled the bottom loose so I could get better access, and pulled the wire and crimp on clip off and laid it against the dryer for this shot.

This plug is at the END of the heating coil elements, and apparently gets rather warm/hot...note the blue discoloration of the prong! The copper wire was STIFF, the crimp on clip was actually MELTED apart from the wire!!!

So...I went to my local auto parts store, got some nice 10-12 gauge 1/4" crimp on clips for a few bucks, cut about 2" off of the end of the burnt wire to get to clean copper, stripped the insulation back a bit, and crimped on a new connector, plugged it back onto the heating element prong, put it all back together, and VIOLA it's heating again!!!!

SO....nice not to have to replace the $85.00 heating element, just a $0.50 crimp on connector and a couple of hours of labor....now I can do my laundry this weekend!!

Hope you enjoyed the show! T.C.

This is NO April's Fool thread. A couple of nights ago, was doing the laundry, and noticed that the dryer seemed to be running a long time. Checked the clothes....and they were still damp and COLD!

Rechecked the settings, changed from SENSOR dry to Timed Dry, same thing, NO HEAT!

Rechecked the settings, changed from SENSOR dry to Timed Dry, same thing, NO HEAT!

Read up on it...a Maytag Commercial Grade dryer from some 16 years ago, found a parts/price listing....and figured the most common cause of loss of heat was a fried/broken heating element! Found one for about $85.00!

But I also found some other repair links, learned about testing it with an OHMMETER first!

But I also found some other repair links, learned about testing it with an OHMMETER first!

Tonight after dinner, got into it, had to pull it out from it's upstairs hallway slot, disconnect the power and exhaust vent, then pulled the front off first.

Then got down and looked up/back towards the heating element...and was a bit surprised to see this!

Pulled the bottom loose so I could get better access, and pulled the wire and crimp on clip off and laid it against the dryer for this shot.

This plug is at the END of the heating coil elements, and apparently gets rather warm/hot...note the blue discoloration of the prong! The copper wire was STIFF, the crimp on clip was actually MELTED apart from the wire!!!

So...I went to my local auto parts store, got some nice 10-12 gauge 1/4" crimp on clips for a few bucks, cut about 2" off of the end of the burnt wire to get to clean copper, stripped the insulation back a bit, and crimped on a new connector, plugged it back onto the heating element prong, put it all back together, and VIOLA it's heating again!!!!

SO....nice not to have to replace the $85.00 heating element, just a $0.50 crimp on connector and a couple of hours of labor....now I can do my laundry this weekend!!

Hope you enjoyed the show! T.C.

Comment