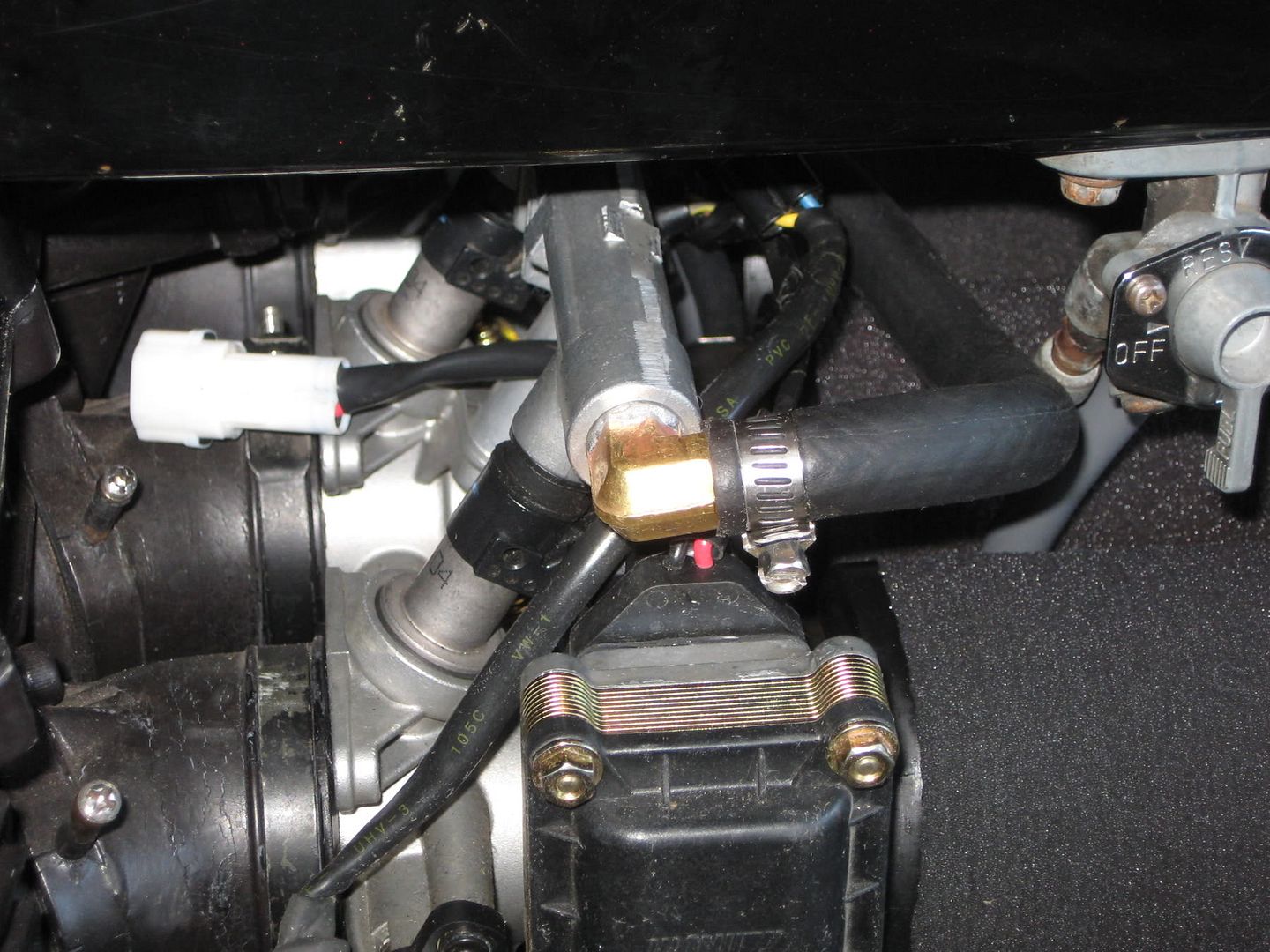

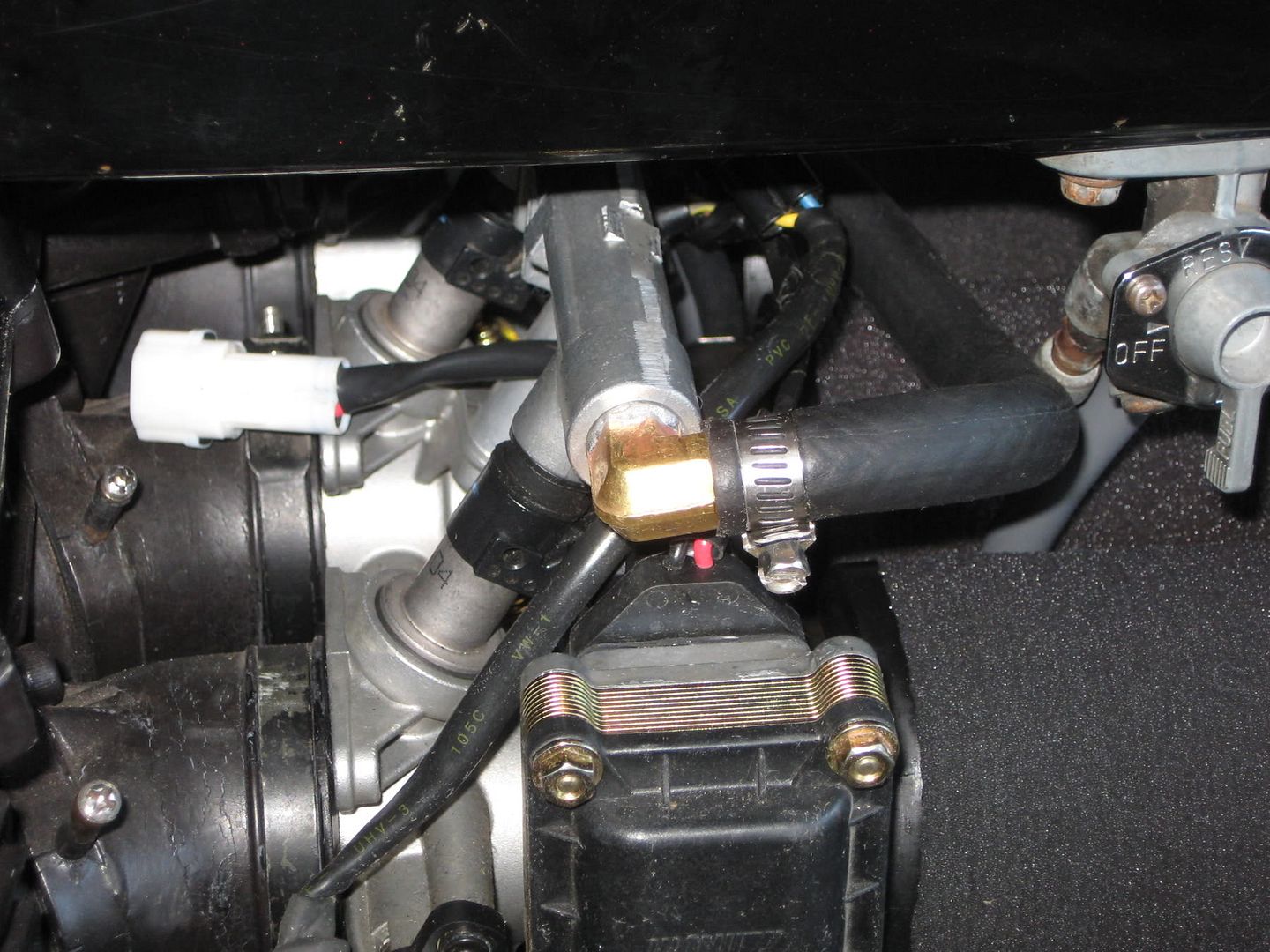

The picture below (currently a HUGE pain in my side as it has kept me from making my first test run on FI for 2 days now) is of a threaded brass elbow I absolutely cannot get to seal in the aluminum fuel rail for the life of me. I have used fuel tape and tapped it, and tried everything but epoxy (which is the absolute last resort due to its permanent nature). Last night I had the great idea to solder it. It would seal it, hold up to the pressure (38-45 psi), and be removable with heat. I got it all put back together for like the millionth time and it leaked. Other than electrical, I don't have much experience soldering. Some proper procedure, equipment, and material recommendations would rock.

thanXS in advance.

.

.

thanXS in advance.

.

.

- NOW IT'S FOR SALE! $1,800 OBO

- NOW IT'S FOR SALE! $1,800 OBO

. I guess I will try the fuel tape again and it that doesn't work, I will have to decide between the fuel tank epoxy and waiting on Muggyweld Super Allow 1.

. I guess I will try the fuel tape again and it that doesn't work, I will have to decide between the fuel tank epoxy and waiting on Muggyweld Super Allow 1.

Comment